Oxaliplatin chitosan-stearic acid grafting micelle and application

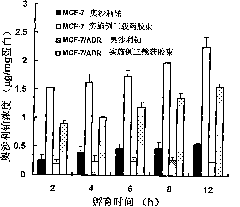

A technology of oxaliplatin and stearic acid, which is applied in the field of preparation of oxaliplatin chitosan-stearic acid graft micelles, can solve the problems of not many, difficult polymer micelles, etc., and achieve the improvement of cell Toxicity, improve clinical anti-tumor efficacy, increase the effect of intracellular drug concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Preparation of low molecular weight chitosan

[0020] Get 90g of chitosan (95% degree of deacetylation) with a commercially available molecular weight of 450kDa, add it to 3000mL of 1.25% (v / v) hydrochloric acid aqueous solution, under the temperature condition of 55~60°C, after swelling for 2 hours, Add 5% cellulase (w / w), and degrade at a temperature of 55-60°C. Control the reaction temperature and time to obtain low molecular weight chitosan. The resulting degradation reaction solution was fractionated by ultrafiltration using 50Kda and 10Kda ultrafiltration membranes (Biomax-10, Millipore Co., USA), and the ultrafiltrate with a molecular weight of 10-50Kda was taken for freeze-drying. Gel permeation chromatography was used to measure chitosan molecular weight, using TSK-gel G3000SW chromatographic column, 0.1mol / L sodium acetate (pH6.0) as mobile phase, with molecular weight 0.73, 5.9, 11.8, 47.3, 212.0, 788.0Kda glucose The elution curve of the polysaccharide ...

Embodiment 2

[0029] 1) Preparation of low molecular weight chitosan

[0030] Get 90g of chitosan (95% degree of deacetylation) with a commercially available molecular weight of 450kDa, add it to 3000mL of 1.25% (v / v) hydrochloric acid aqueous solution, under the temperature condition of 55~60°C, after swelling for 2 hours, Add 5% cellulase (w / w), and degrade at a temperature of 55-60°C. Control the reaction temperature and time to obtain low molecular weight chitosan. The resulting degradation reaction solution was fractionated by ultrafiltration using 50Kda and 10Kda ultrafiltration membranes (Biomax-10, Millipore Co., USA), and the ultrafiltrate with a molecular weight of 10-50Kda was taken for freeze-drying. Gel permeation chromatography was used to measure chitosan molecular weight, using TSK-gel G3000SW chromatographic column, 0.1mol / L sodium acetate (pH6.0) as mobile phase, with molecular weight 0.73, 5.9, 11.8, 47.3, 212.0, 788.0Kda glucose The elution curve of the polysaccharide ...

Embodiment 3

[0039] 1) Preparation of low molecular weight chitosan

[0040] Get 90g of chitosan (95% degree of deacetylation) with a commercially available molecular weight of 450kDa, add it to 3000mL of 1.25% (v / v) hydrochloric acid aqueous solution, under the temperature condition of 55~60°C, after swelling for 2 hours, Add 5% cellulase (w / w), and degrade at a temperature of 55-60°C. Control the reaction temperature and time to obtain low molecular weight chitosan. The resulting degradation reaction solution was fractionated by ultrafiltration using 50Kda and 10Kda ultrafiltration membranes (Biomax-10, Millipore Co., USA), and the ultrafiltrate with a molecular weight of 10-50Kda was taken for freeze-drying. Gel permeation chromatography was used to measure chitosan molecular weight, using TSK-gel G3000SW chromatographic column, 0.1mol / L sodium acetate (pH6.0) as mobile phase, with molecular weight 0.73, 5.9, 11.8, 47.3, 212.0, 788.0Kda glucose The elution curve of the polysaccharide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com