Method for preparing granular herbal pieces prepared for decoction through steam explosion of monkshood

A technology of granule decoction pieces and aconite, which is applied in the directions of pharmaceutical formulations, medical preparations containing active ingredients, and bulk transportation, etc., can solve the problems of long time required, high preparation cost, loss of active ingredients, etc., to reduce medical expenses, The effect of improving the dissolution rate and promoting the release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

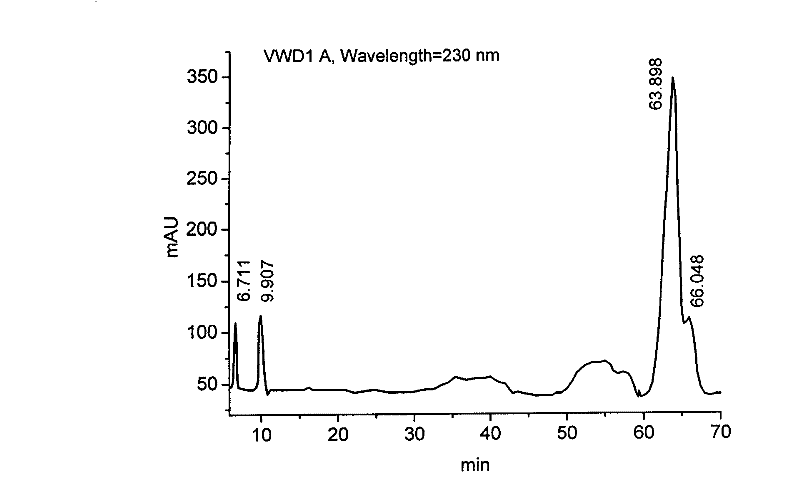

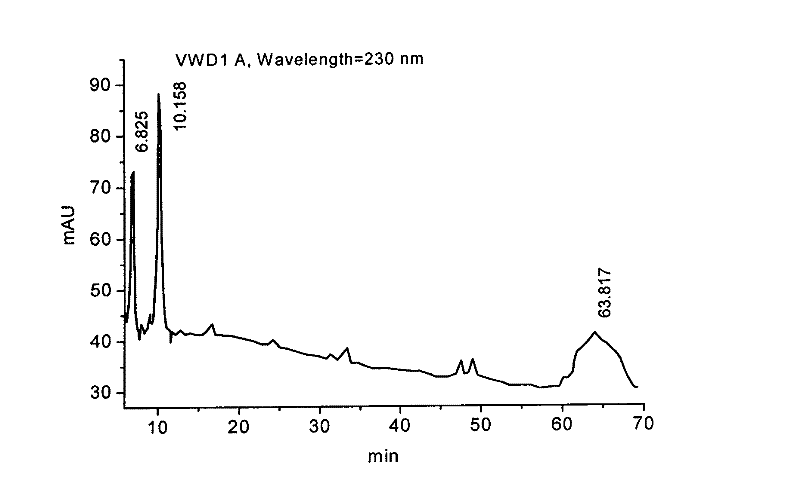

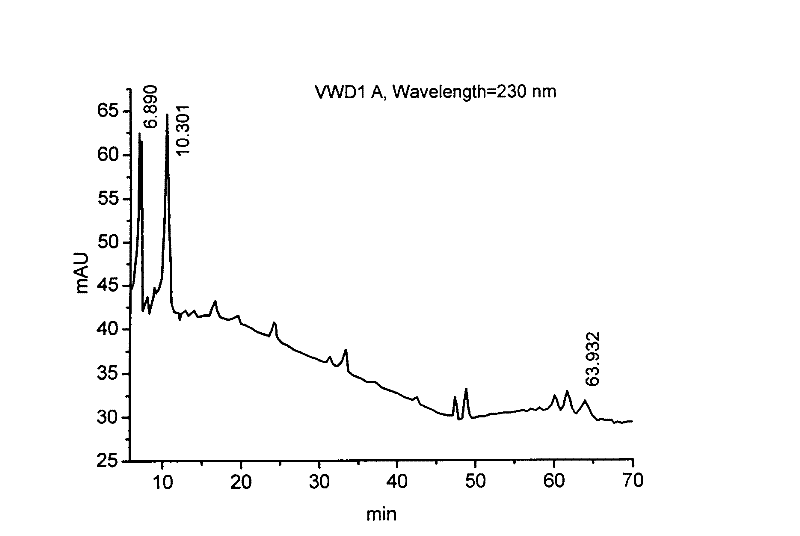

Image

Examples

Embodiment 1

[0020] Add 400g of succulent slices to 400mL of distilled water, soak for 16h, and steam-explode in a 4L test steam explosion tank under the condition of 155°C-2min. After steam-explosion treatment, dry with hot air at 50°C. The dried steam-exploded aconite is crushed to 20 mesh with a traditional Chinese medicine pulverizer to obtain the steam-exploded granule of the aconite.

Embodiment 2

[0022] Add 200kg of Shengfu Tablets, add 250L of distilled water, soak for 24h, in 0.5m 3 The steam explosion tank is processed under the condition of 175°C-2min. After the steam explosion treatment, it is dried with hot air at 40°C. The dried aconite is crushed to 10 mesh with a traditional Chinese medicine crusher to obtain the steam explosion of the aconite. Granules.

Embodiment 3

[0024] Fresh aconite 400g, sliced and processed in a 4L steam explosion tank under the condition of 175°C-2min for steam explosion, after steam explosion treatment, hot air drying was carried out at 40°C, and the dried aconite was crushed with a traditional Chinese medicine grinder to The 10-mesh steam-explosion granule of aconite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com