Method for measuring content of phosphorus and iron in catalyst by using X-ray fluorescence method

A co-catalyst, X-ray technology, used in measurement devices, preparation of test samples, material analysis using wave/particle radiation, etc., to achieve accurate results, fast analysis speed, and high precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

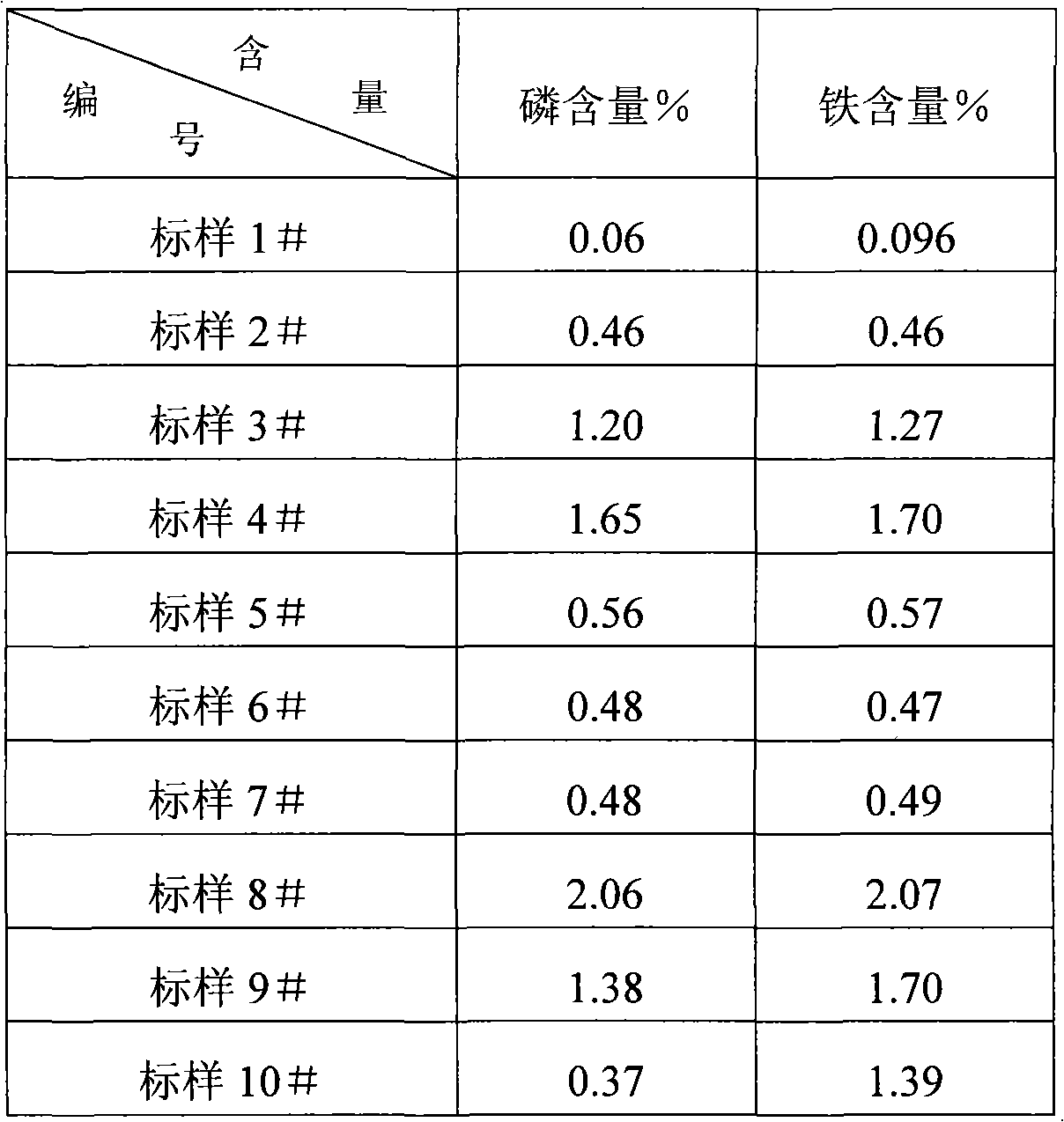

[0031] Preparation of standard samples

[0032] High-purity SiO 2 (purity 99.9%) and high purity Al 2 o 3 (Analytical pure) Mix evenly at a mass ratio of 3:7, then roast at 800°C for 1 hour to make a standard carrier; add a predetermined amount of phosphorus and iron standard solutions, and then add 2 o 3 : CeO 2 :Pr 5 o 11 :Nd 2 o 3 Mixed rare earths with a mass ratio of 20:70:2:2; add absolute ethanol, grind and mix to a uniform powder, transfer the powder into a porcelain crucible, and finally evaporate and dry, which is the standard sample A, in which phosphorus, iron See Table 1 for the content.

[0033] Table 1 Contents of phosphorus and iron in standard sample A

[0034]

[0035] The sample compression method is to add 1g of sample to the rimmed model, spread it evenly, and then add 1.5g of high-density polyethylene to it at 8000 kg / cm 2 compressed into tablets.

Embodiment 2

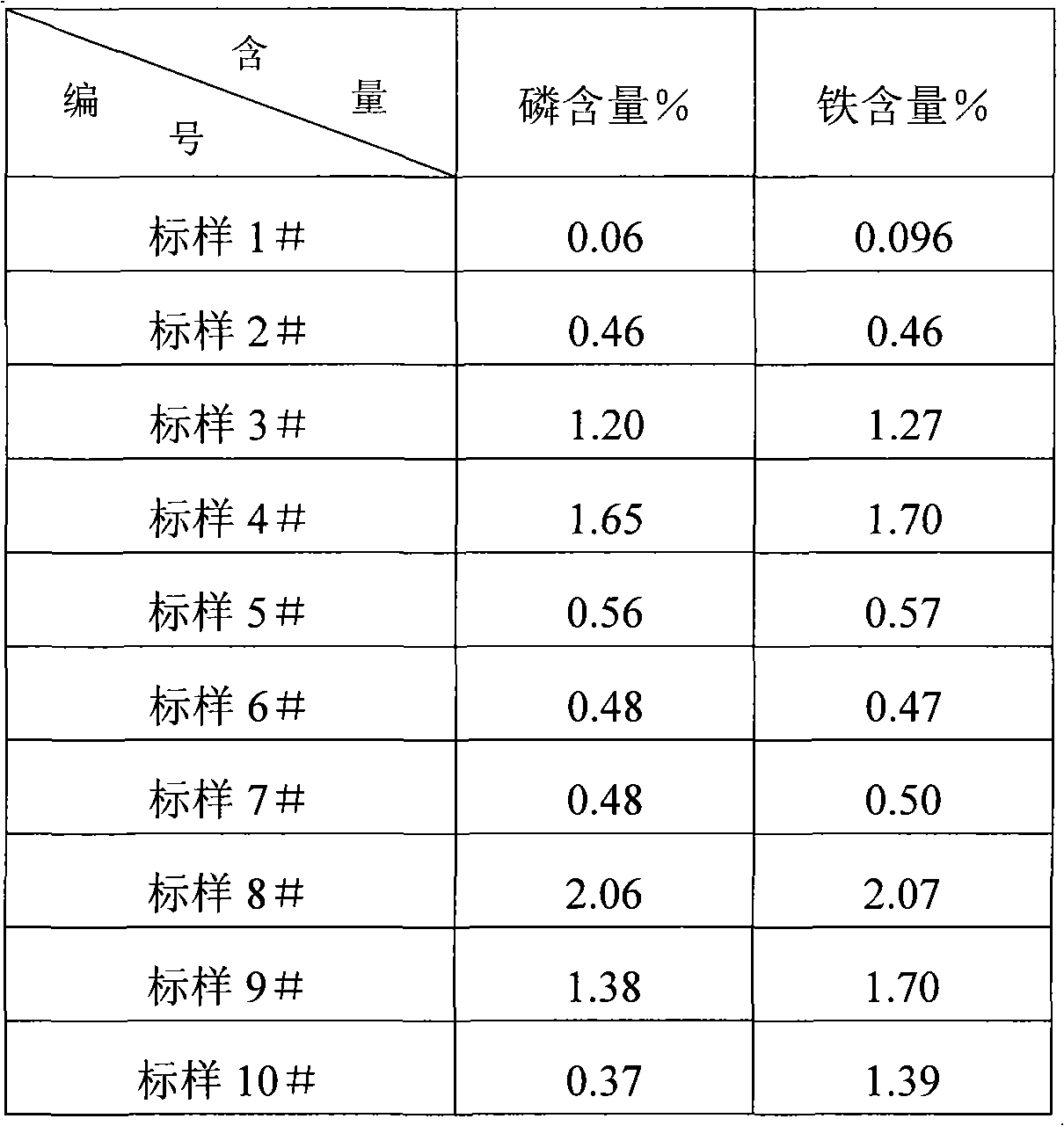

[0037] The preparation of standard sample B (SiO in the standard sample 2 :Al 2 o 3 The mass ratio is 3:7)

[0038] Accurately measure 10ml of the prepared phosphorus and iron solution, add it to 10.0023g of ZSM-5 molecular sieves roasted at 800°C for 1 hour, add 2g of mixed rare earth (La 2 o 3 : CeO 2 :Pr 5 o 11 :Nd 2 o 3 The mass ratio is 20:70:2:2), add 50ml of absolute ethanol (analytical grade), grind and mix until uniform. Then add 8g of pseudo-boehmite, 4g of alumina sol and 20g of kaolin, then add about 200ml of absolute ethanol (analytical grade), grind and mix until uniform, finally evaporate and dry, which is the standard sample B, wherein the contents of phosphorus and iron are shown in Table 2. Adopt the tabletting method identical with embodiment 1.

[0039] Table 2 Contents of phosphorus and iron in standard sample B

[0040]

Embodiment 3

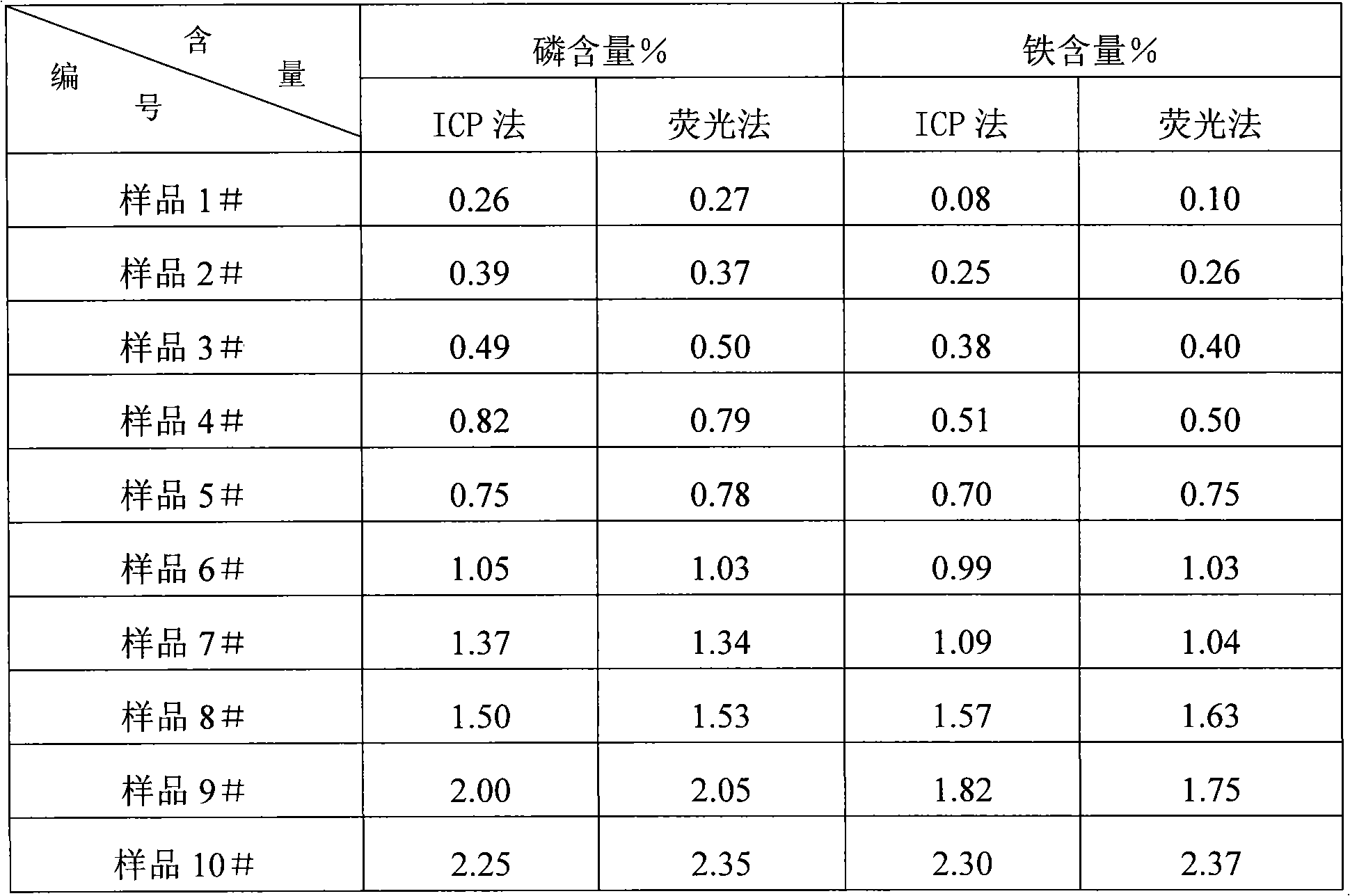

[0042] By measuring the characteristic spectral line intensity I of phosphorus and iron elements in standard samples A and B respectively i , to get the standard curve equation X i = aI i 2 +bI i +c, where X i is the apparent content of phosphorus and iron, I i is the characteristic spectral line intensity of the element, and a, b, and c are the coefficients of the standard curve equation. Since the matrix effect is serious in X-ray fluorescence analysis, the standard curve equation must be corrected. The present invention corrects and adopts empirical equation Wi=(aI i 2 +bI i +c)(1+∑AijWj) to obtain the correction coefficient Aij, Aij is the correction coefficient for the influence of metal j in the standard sample on the determination of metal i, and Wj is the apparent content of metal element j in the standard sample.

[0043] The relationship curve between the apparent concentration and the spectral line intensity obtained by fitting the content of phosphorus and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com