Method for improving salt resistance of lawn plant by filling soil through adopting waste colloidal particle as salt storing layer

A technology of waste rubber particles and salt storage, which is applied in the field of improving the salt resistance of lawn plants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

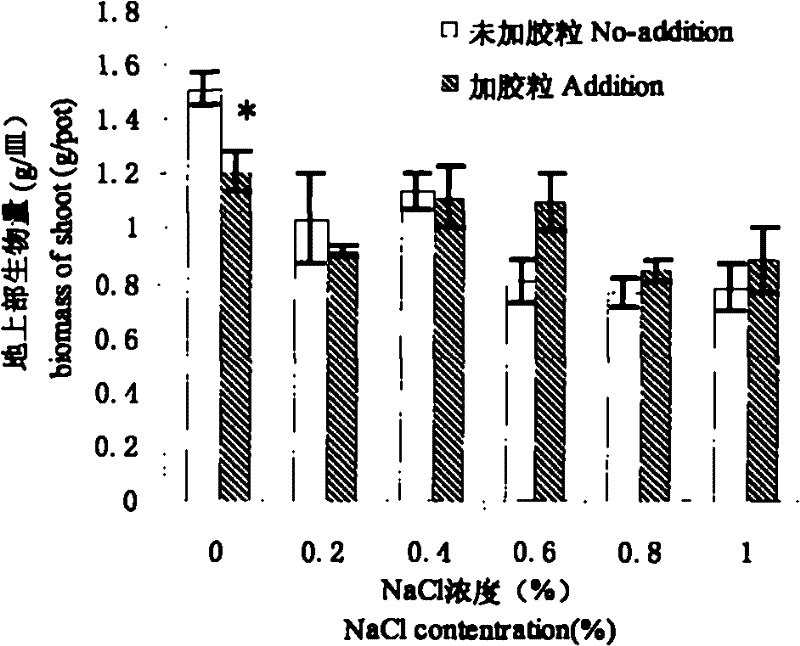

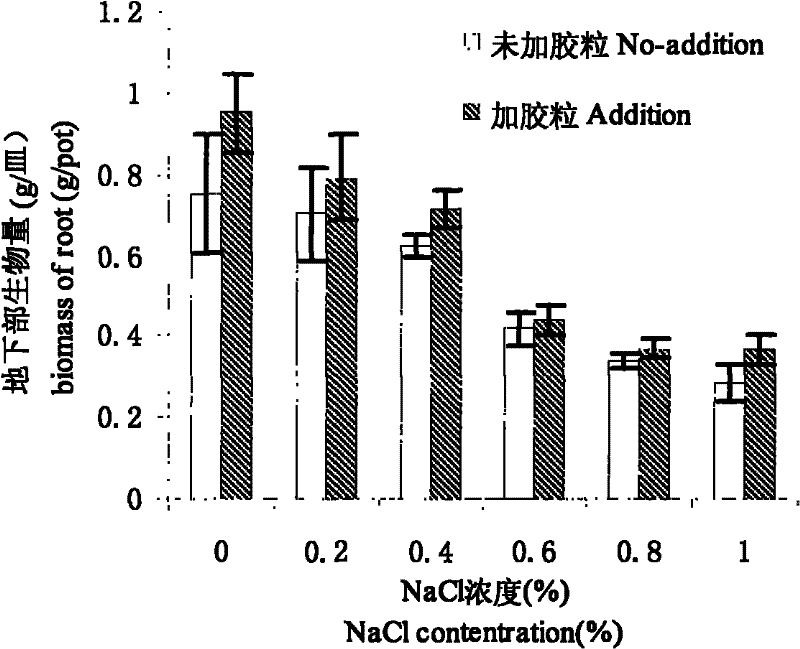

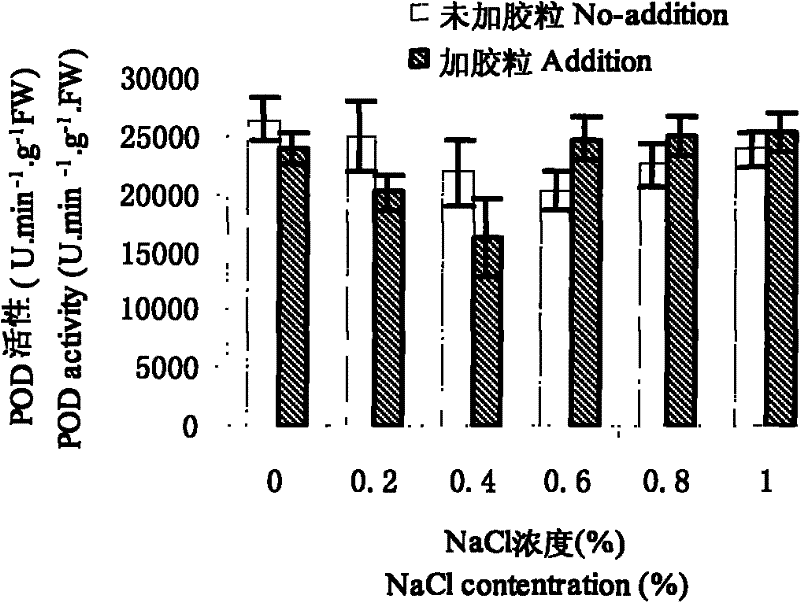

[0049] (1) Adopting the method of tall fescue potted planting, put the waste rubber particles with a diameter of 0.5mm as the salt storage layer on the bottom of the container at 20 cm, and place the soil on it to form a matrix salt storage layer, wherein the ratio of soil to rubber particles is 10 : 1, the seeding rate of every pot of tall fescue is 0.5g;

[0050] (2) Salt stress is carried out after sowing 15 days after the seedlings have fully emerged, and the stress mode is progressive stress, that is, once every 5 days, adding an aqueous solution containing 0.2% NaCl to the salt storage layer matrix each time, and the stress is completed after 20 days;

[0051] (3) After the stress was finished, tall fescue continued to be cultivated for 15 days, and the above-ground parts of the plants were taken to measure various physiological indicators; wherein the average temperature during the test was 18°C, and the average relative humidity was 37.1%; the light was natural incident...

Embodiment 2

[0054] (1) Adopting the method of tall fescue potted planting, put the waste rubber particles with a diameter of 1mm as the salt storage layer at the bottom of the container 30cm, and place the soil on it to form a matrix, wherein the ratio of soil to rubber particles is 10:1, and each The sowing amount of potted tall fescue is 0.5g;

[0055] (2) Salt stress is carried out after sowing 15 days after the seedlings have fully emerged, and the stress mode is progressive stress, that is, once every 5 days, adding an aqueous solution containing 0.4% NaCl to the salt storage layer matrix each time, and the stress is completed after 20 days;

[0056] (3) After the stress was finished, tall fescue continued to be cultivated for 15 days, and the above-ground parts of the plants were taken to measure various physiological indicators; wherein the average temperature during the test was 18°C, and the average relative humidity was 37.1%; the light was natural incident light; During the cul...

Embodiment 3

[0058] (1) Adopting the method of tall fescue potted planting, put the waste rubber particles with a diameter of 0.8mm as the salt storage layer at the bottom of the container at 30 cm, and place the soil on it to form a matrix, wherein the ratio of soil to rubber particles is 10:1, The sowing amount of each pot of tall fescue is 0.5g;

[0059] (2) Salt stress is carried out after sowing 15 days after the seedlings have fully emerged, and the stress mode is progressive stress, that is, once every 5 days, adding an aqueous solution containing 0.8% NaCl to the salt storage layer matrix each time, and the stress is completed after 20 days;

[0060] (3) After the stress was finished, tall fescue continued to be cultivated for 15 days, and the above-ground parts of the plants were taken to measure various physiological indicators; wherein the average temperature during the test was 18°C, and the average relative humidity was 37.1%; the light was natural incident light; During the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com