Silicone-type coatings and preparation method thereof

A silicone resin and coating technology, applied in the coating and other directions, can solve the problems of unfavorable electronic and electrical repair, easy dust accumulation, poor combination of elasticity, hardness and toughness, etc., to achieve comprehensive protection during production and use, shock resistance and damage resistance. The effect of improving airtightness, good air tightness and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] Synthesis of components

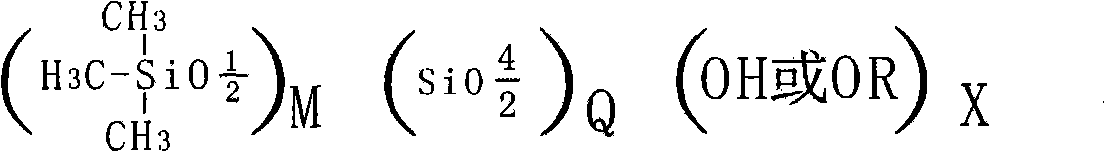

[0068] A1: Preparation of MQ silicone resin containing hydroxyl (-OH) or alkoxy (-OR)

[0069] In a four-necked bottle, add 448g of 16-18% hydrochloric acid aqueous solution. Under rapid stirring, add 3# water glass and water mixture (sio 2 Content 11.13%) 546g. After the addition is complete, add 220 grams of isopropanol over 3 minutes, stir for 1-2 minutes, then add a mixture of 77 grams of toluene and 20 grams of trimethylchlorosilane after 20 minutes, keep it at reflux temperature for 1 hour; then add toluene After 120g is cooled, separate into layers and wash with water. Then the water and part of the solvent are removed under reduced pressure to obtain a 50% solid content product and toluene mixture, structural formula

[0070] Put 100g of the above resin into a flask, add 10g of methyl orthosilicate and 15g of acetic acid, stir and react at 60-65°C for 3-4 hours, and then remove low molecular reactants and unreacted substances under reduced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com