Vegetable oil modified ethyl cellulose and preparation method thereof

A technology for the modification of ethyl cellulose and vegetable oil, which is applied in the field of modified ethyl cellulose synthesis, and can solve problems such as environmental pollution, brittle texture and easy breakage, affecting the performance and service life of ethyl cellulose materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

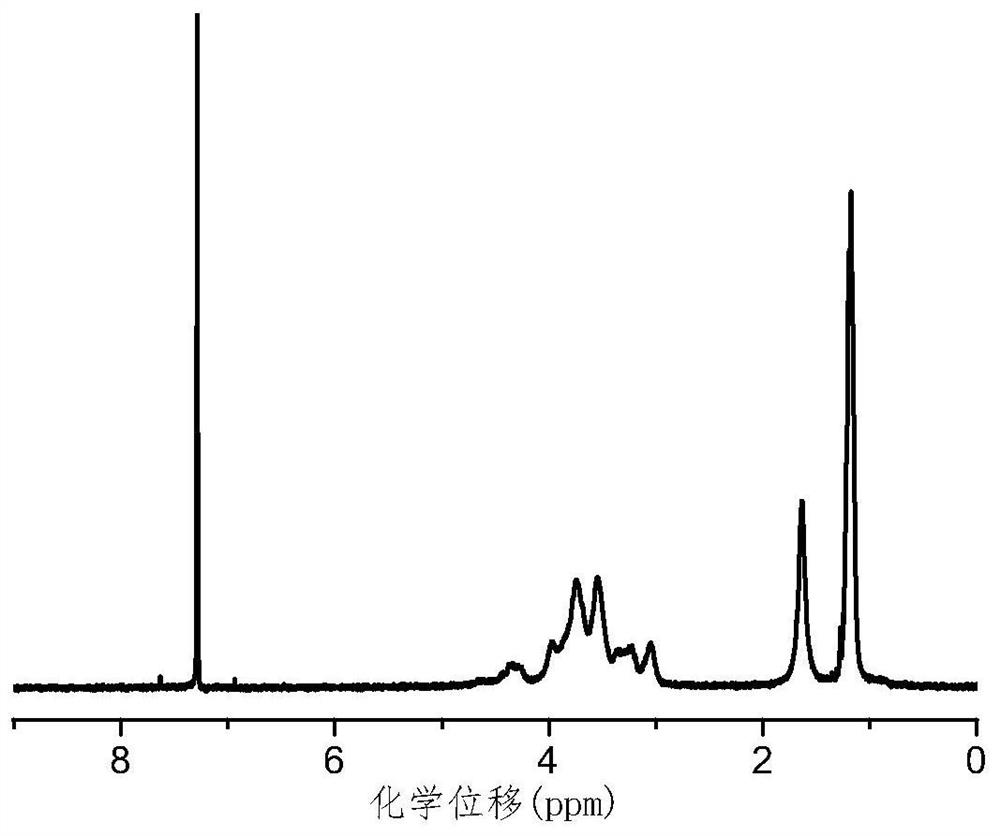

[0025] 3 g of soybean oil and 7 g of ethyl cellulose were dissolved in 150 mL of tetrahydrofuran, 0.1 g of sodium methoxide was added, the temperature was controlled at 60 ° C, and the reaction was stirred for 24 h under nitrogen protection. 10wt.% methanol aqueous solution is used to precipitate the polymer, and the soybean oil modified ethyl cellulose is obtained after separation and drying. Use proton nuclear magnetic spectrum to utilize internal standard method to measure the content of unsaturated double bond in the modified ethyl cellulose, the results are shown in Table 1 and figure 2 .

Embodiment 2

[0027] 4g of soybean oil and 6g of ethyl cellulose were dissolved in 150mL of tetrahydrofuran, 0.1g of sodium methoxide was added, the temperature was controlled at 60°C, and the reaction was stirred for 24h under nitrogen protection. 10wt.% methanol aqueous solution is used to precipitate the polymer, and the soybean oil modified ethyl cellulose is obtained after separation and drying. The content of unsaturated double bonds in the modified ethyl cellulose was determined by the internal standard method by proton nuclear magnetic spectroscopy, and the results are shown in Table 1.

Embodiment 3

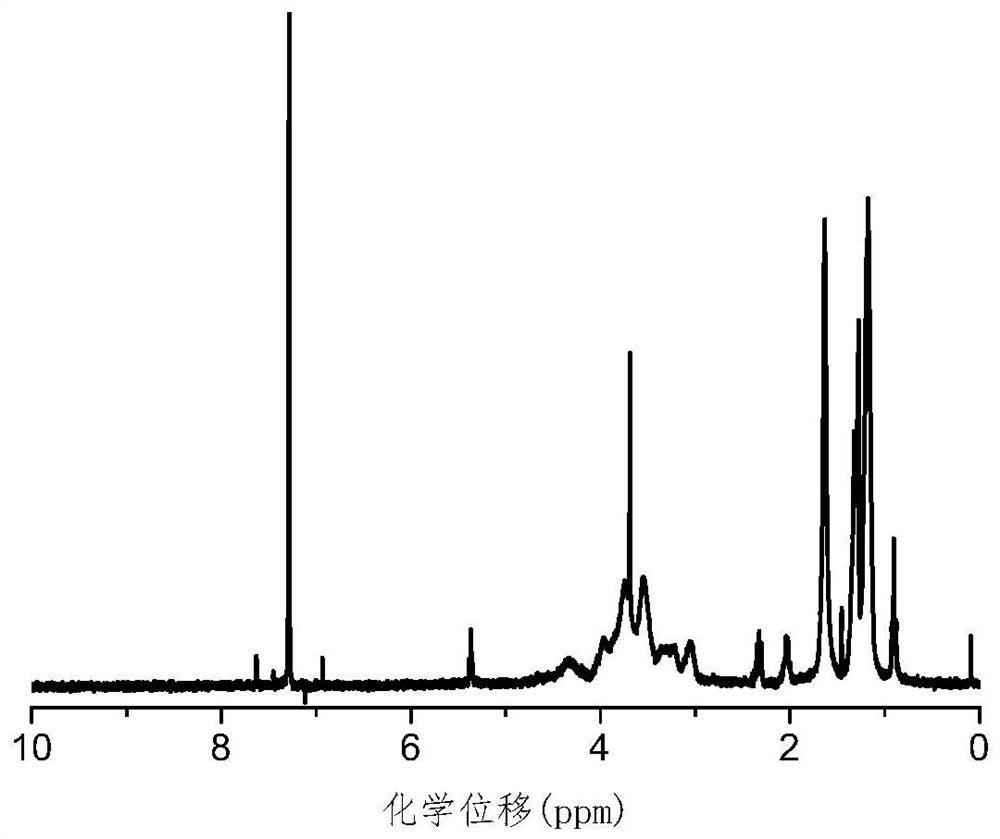

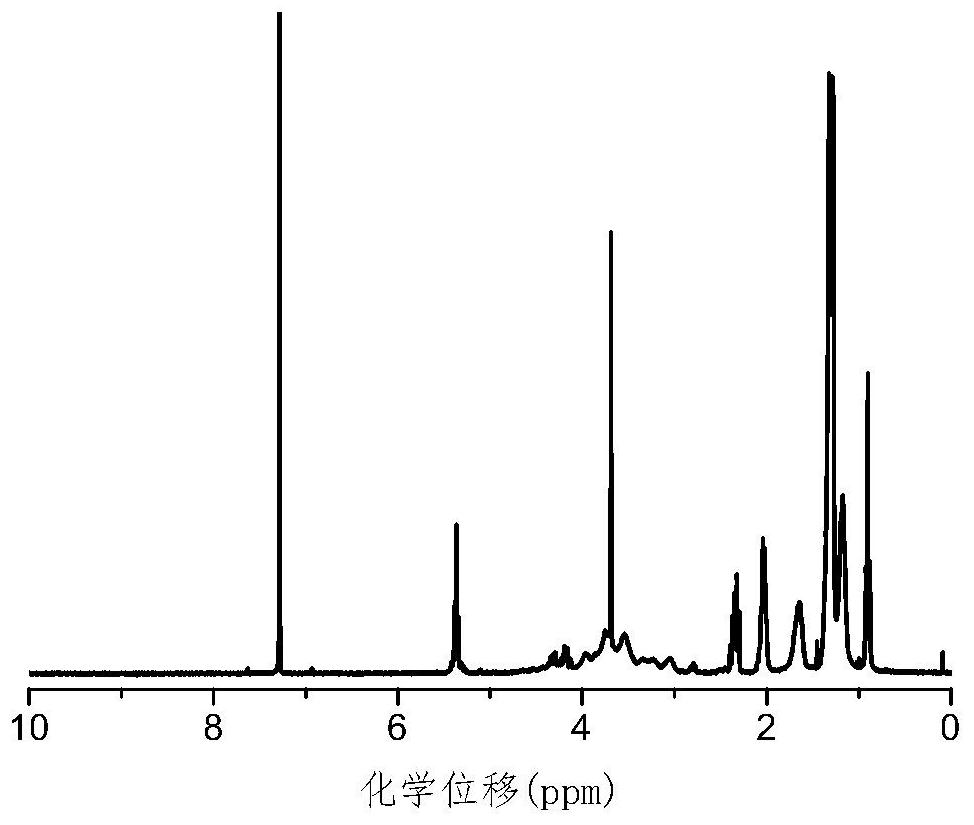

[0029] 5g of soybean oil and 5g of ethyl cellulose were dissolved in 150mL of tetrahydrofuran, 0.1g of sodium methoxide was added, the temperature was controlled at 60°C, and the reaction was stirred for 24h under nitrogen protection. 10wt.% methanol aqueous solution is used to precipitate the polymer, and the soybean oil modified ethyl cellulose is obtained after separation and drying. Use proton nuclear magnetic spectrum to utilize internal standard method to measure the content of unsaturated double bond in the modified ethyl cellulose, the results are shown in Table 1 and image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com