Method for preparing temperature-resistant type compound bonding agent

A composite adhesive, temperature-resistant technology, applied in the direction of adhesives, etc., can solve the problems of poor wetting and leveling performance, high molecular weight, etc., and achieve the effects of saving organic diluent solvents, large cross-linking density, and reducing use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment provides a method for preparing a temperature-resistant composite adhesive, which can prepare a high-performance temperature-resistant composite adhesive used in composite flexible packaging film materials. The preparation method includes:

[0026] Prepare polyester polyol earlier, each raw material is all by mass percentage in the following steps;

[0027] a. Esterification reaction:

[0028] 3-6% trimethylolpropane, 20-30% terephthalic acid, 20-30% sebacic acid, 15-25% diethylene glycol, 15-25% neopentyl Diol is added into the polyester synthesis kettle, the temperature is raised to 210-230° C., and the reaction is carried out for 2 to 3 hours to complete the esterification; in the esterification reaction step, the water output of the polyester synthesis kettle is kept stable at the total amount of each raw material used in the esterification reaction. 0.5~1% / hour of quality, water distillation accounts for 6~12% of the total mass of raw materials use...

Embodiment 2

[0039] This embodiment provides a method for preparing a temperature-resistant composite adhesive, which can prepare a high-performance temperature-resistant composite adhesive used in composite flexible packaging film materials. The preparation method includes:

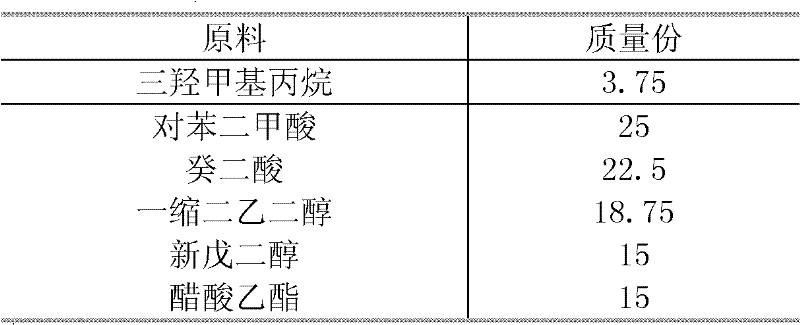

[0040] Prepare adhesive (preparing polyester polyol earlier), get each raw material as follows:

[0041]

[0042] Steps:

[0043] a. Esterification reaction:

[0044] 3.75 mass parts of trimethylolpropane, 25 mass parts of terephthalic acid, 22.5 mass parts of sebacic acid, 18.75 mass parts of diethylene glycol, and 15 mass parts of neopentyl glycol were added to poly In the ester synthesis kettle, heat up to 210-230°C and react for 2.5 hours; during the reaction, pay attention to observe the water outlet of the polyester synthesis kettle, and keep the water output stable at 0.5-1% of the total mass of each raw material per hour; distill water 9.42 parts by mass; the esterification reaction is completed, and the...

Embodiment 3

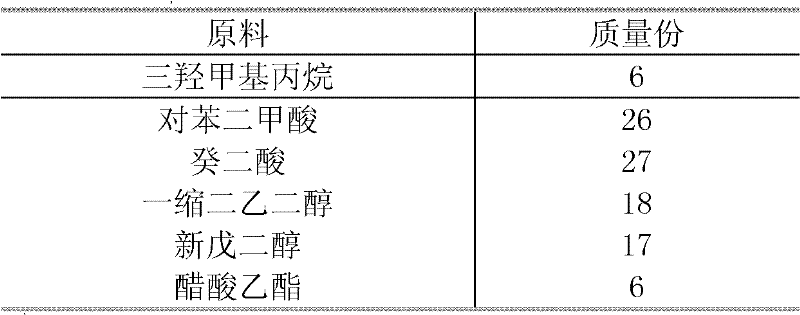

[0052] This embodiment provides a method for preparing a temperature-resistant composite adhesive, which can prepare a high-performance temperature-resistant composite adhesive used in composite flexible packaging film materials. The preparation method includes:

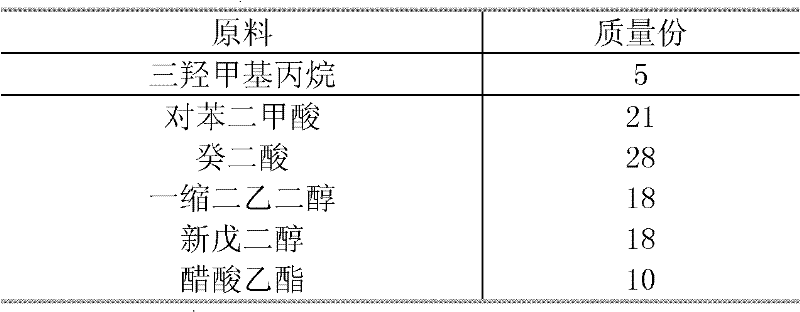

[0053] Prepare adhesive, get each raw material according to the table:

[0054]

[0055] Steps:

[0056] a. Esterification reaction:

[0057] 5 parts by mass of trimethylolpropane, 21 parts by mass of terephthalic acid, 28 parts by mass of sebacic acid, 18 parts by mass of diethylene glycol, and 18 parts by mass of neopentyl glycol were added to the poly In the ester synthesis kettle, heat up to 210-230°C and react for 3 hours; during the reaction, pay attention to observe the water outlet of the polyester synthesis kettle, and keep the water output stable at 0.5-1% of the total mass of raw materials used in the esterification reaction per hour , 9.53 parts by mass of distilled water; the esterification reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com