Robot airship control system for overhead line inspection and control method thereof

A technology for inspection robots and control systems, applied in control/regulation systems, vehicle position/route/altitude control, non-electric variable control, etc., can solve problems such as insufficient endurance, high crash risk, and difficulty in loading and unloading insulation. Achieve the effect of reducing inspection dead zone, solving personnel loss, and reducing crash risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Further illustrate the present invention below in conjunction with accompanying drawing.

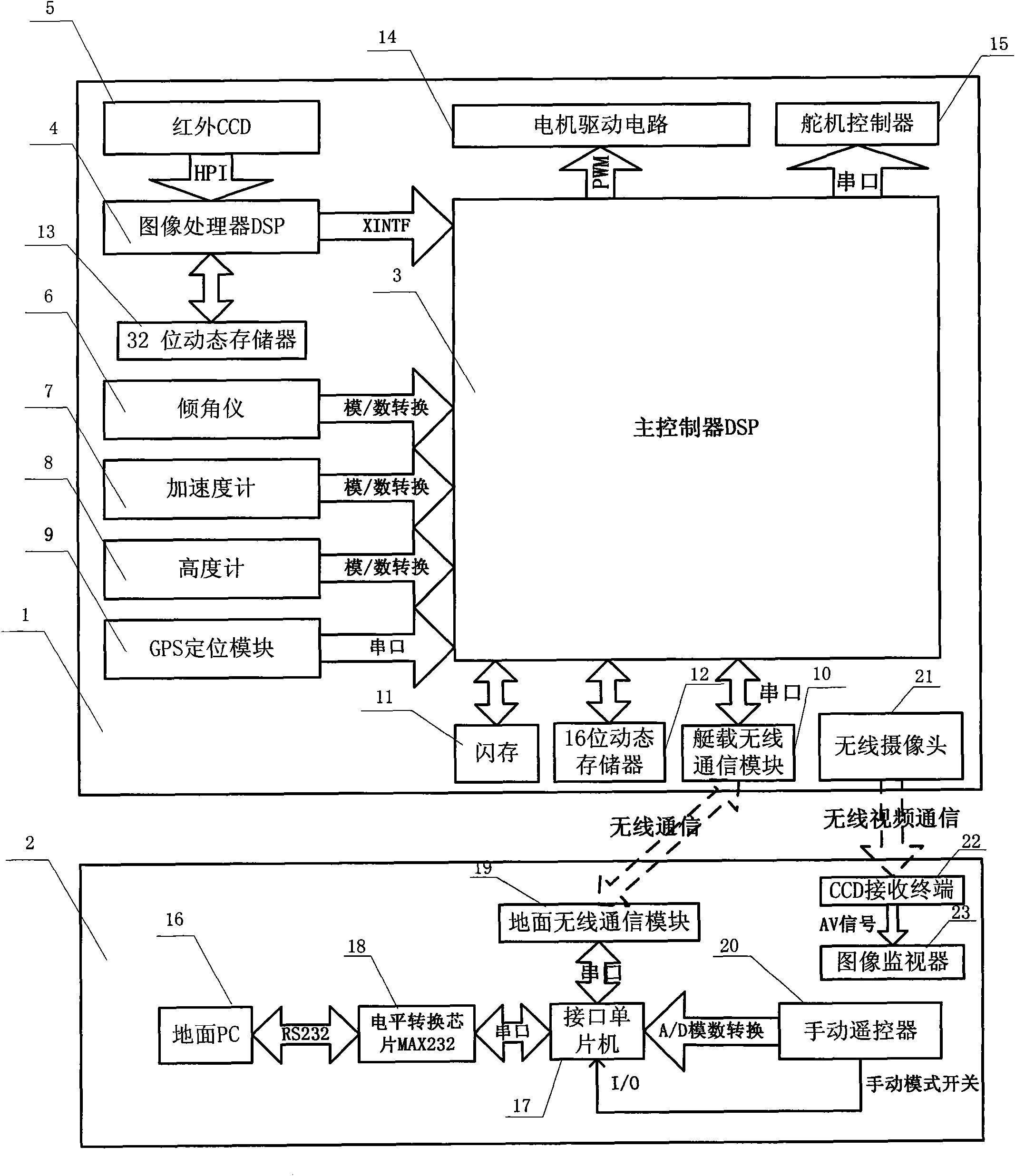

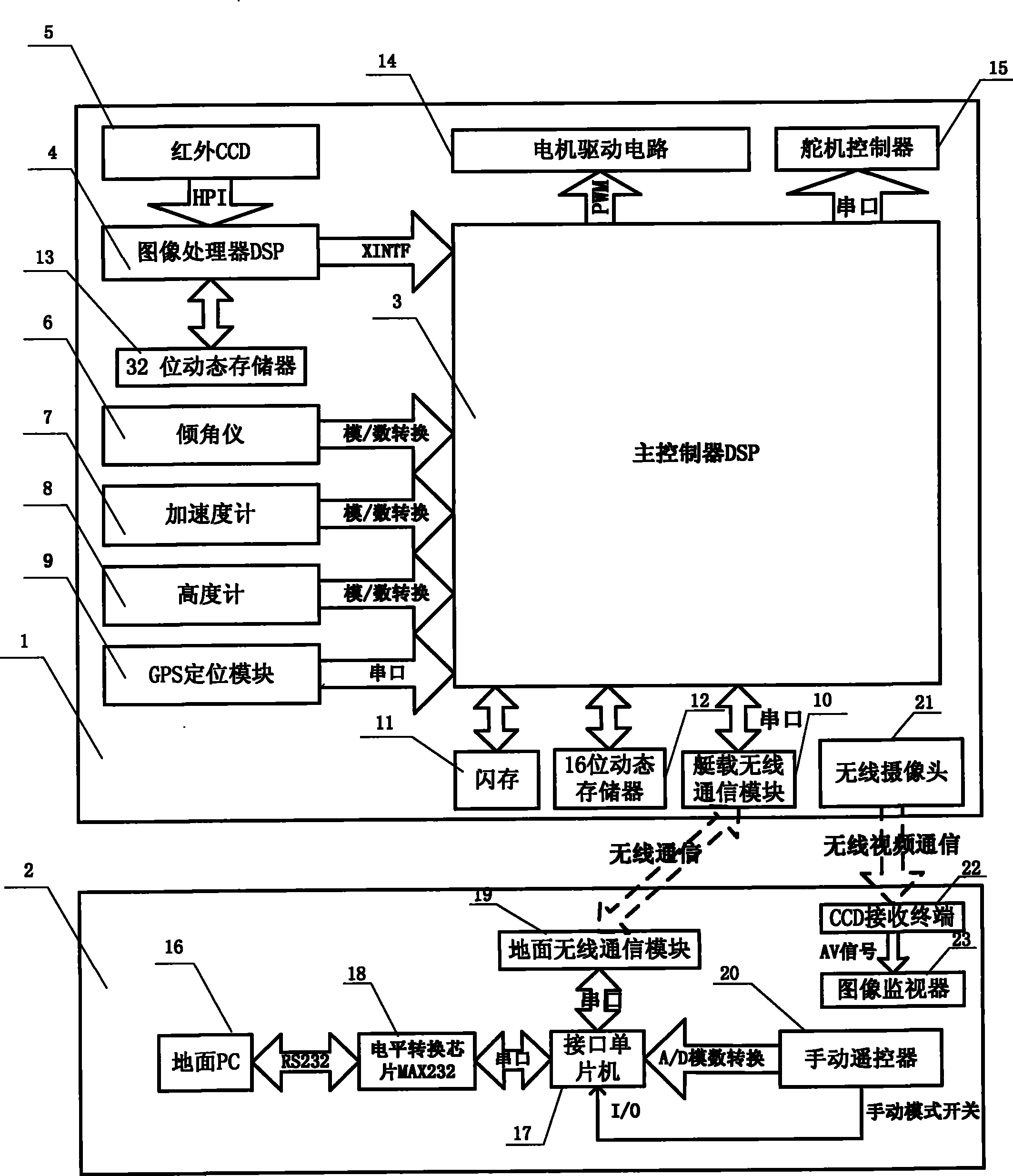

[0033] see figure 1 , the aerial line inspection robot airship control system of the present invention includes two parts, a boat-borne system 1 and a ground system 2, and the boat-borne system 1 includes a main controller DSP3, an image processor DSP4, an infrared CCD5, an inclinometer 6, and an accelerometer 7 , altimeter 8, GSP positioning module 9, boat-borne wireless communication module 10, flash memory 11, 16-bit dynamic memory 12, 32-bit dynamic memory 13, motor drive circuit 14, steering gear controller 15 and wireless camera 21; main controller DSP 3 is connected with the flash memory 11 and the 16-bit dynamic memory 12 through the external extension bus, and the image processor DSP 4 is connected with the 32-bit dynamic memory 13 through the external extension bus; the XINTF port of the image processor DSP 4 is connected to the XINTF of the main controller DSP 3 port; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com