Transparent flexible ultraviolet detector and preparation method thereof

An ultraviolet detector and transparent technology, applied in the field of photodetectors, can solve the problems of complex process, high preparation cost, inflexibility, etc., and achieve the effect of abundant resources and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

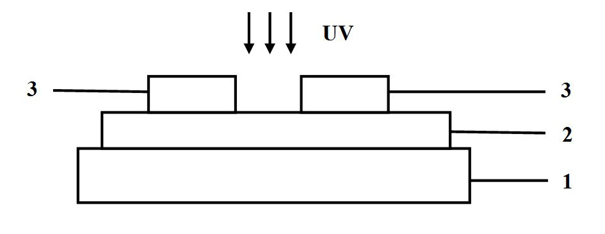

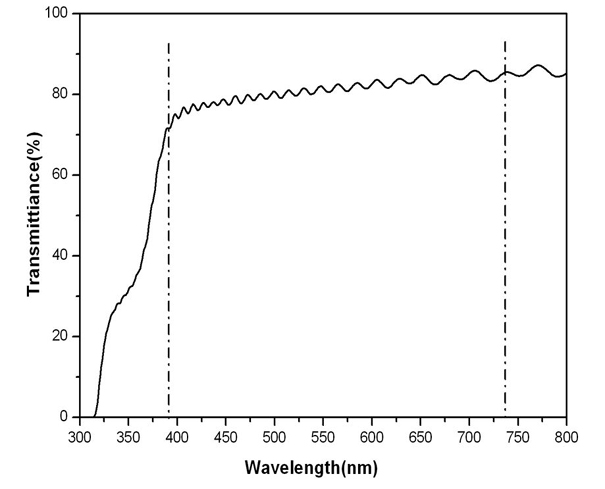

[0022] The ultraviolet detector structure of the present embodiment is as figure 1 As shown, a transparent plastic substrate 1 is included, a 100nm thick ZnO film 2 is deposited on the surface of the transparent plastic substrate 1, a 100nm thick ITO transparent interdigital electrode 3 is arranged on the surface of the ZnO thin film 2, and between adjacent interdigital electrodes The interdigital spacing between them is 600 μm. The material used for the transparent plastic substrate in this embodiment is polyethylene terephthalate (PET) film. The light transmittance of the ultraviolet detector obtained by testing is as follows: figure 2 As shown, the transmittance of the ultraviolet detector in the visible light band reaches 80%, realizing the transparency of the ultraviolet detector.

[0023] The preparation method of the ultraviolet detector of the present embodiment is as follows:

[0024] 1) Clean the polyethylene terephthalate (PET) transparent flexible substrate, dr...

Embodiment 2

[0030] The ultraviolet detector of this embodiment is basically the same as that of Embodiment 1, except that the thickness of the ZnO thin film is 50 nm, the thickness of the ITO interdigitated electrode is 100 nm, and the interdigital distance is 200 μm.

[0031] The preparation method of the ultraviolet detector of this embodiment is the same as that of Embodiment 1, the difference is that the parameters of the pulsed laser deposition are: high-purity oxygen ambient pressure is 50Pa, the pulsed laser energy is 300mJ, the pulsed laser frequency is 3Hz, and the growth time is 30min; The magnetron sputtering parameters are as follows: the ambient pressure of high-purity argon is 5Pa, the sputtering power is 200W, and the sputtering time is 30min.

Embodiment 3

[0033] The ultraviolet detector of this embodiment is basically the same as that of Embodiment 1, except that the thickness of the ZnO thin film is 200 nm, the thickness of the ITO interdigitated electrode is 300 nm, and the interdigital distance is 1000 μm.

[0034] The preparation method of the ultraviolet detector of this embodiment is the same as that of Embodiment 1, the difference is that the parameters of the pulsed laser deposition are: high-purity oxygen ambient pressure is 50Pa, the pulsed laser energy is 300mJ, the pulsed laser frequency is 3Hz, and the growth time is 30min; The magnetron sputtering parameters are as follows: the ambient pressure of high-purity argon is 20Pa, the sputtering power is 80W, and the sputtering time is 200min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Interdigital spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com