Introduction-type roughening nitrogen polar surface gallium nitride based light-emitting diode and manufacturing method thereof

A light-emitting diode, gallium nitride-based technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., to achieve the effect of improving light extraction efficiency, maintaining electrical performance and manufacturing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

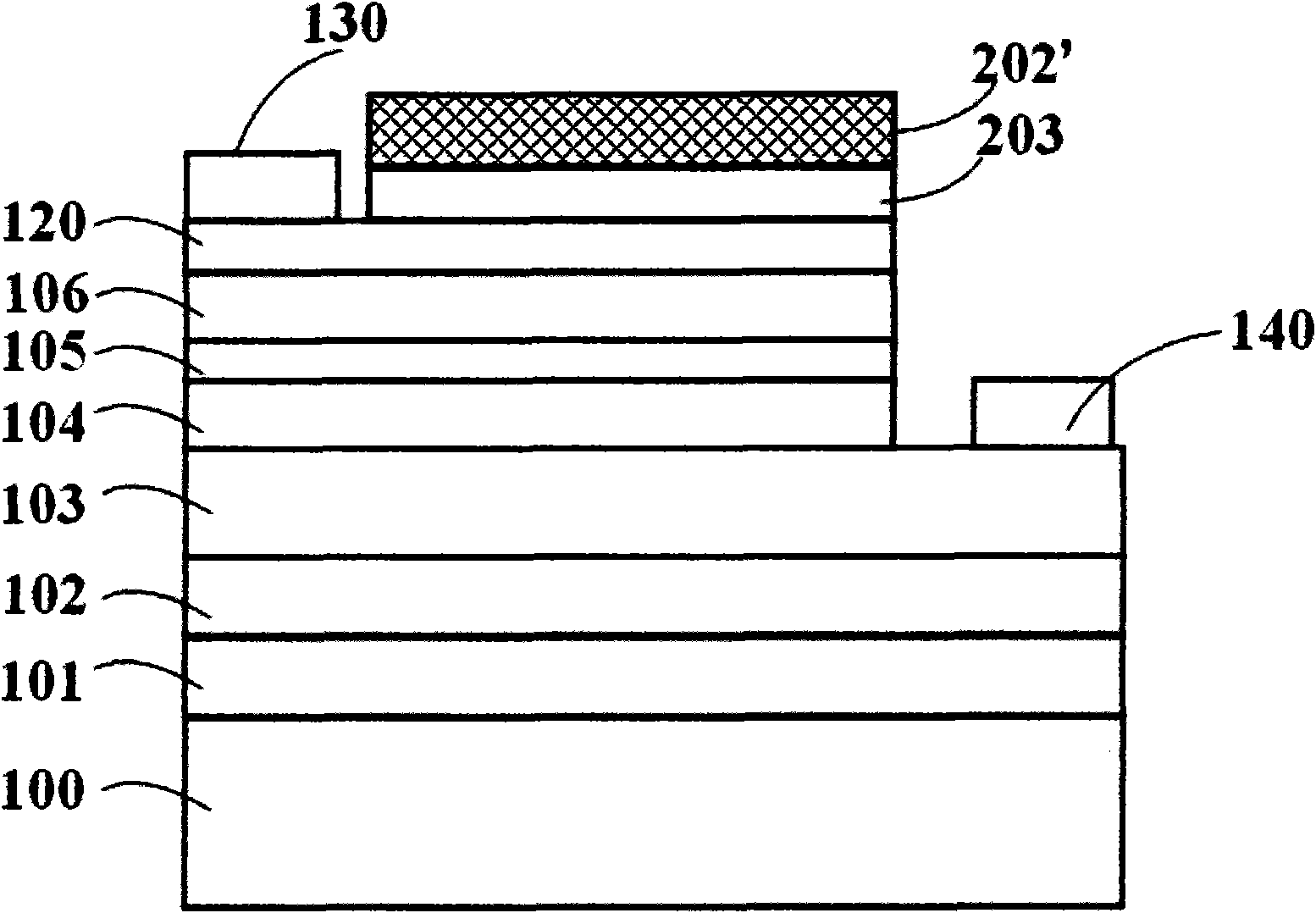

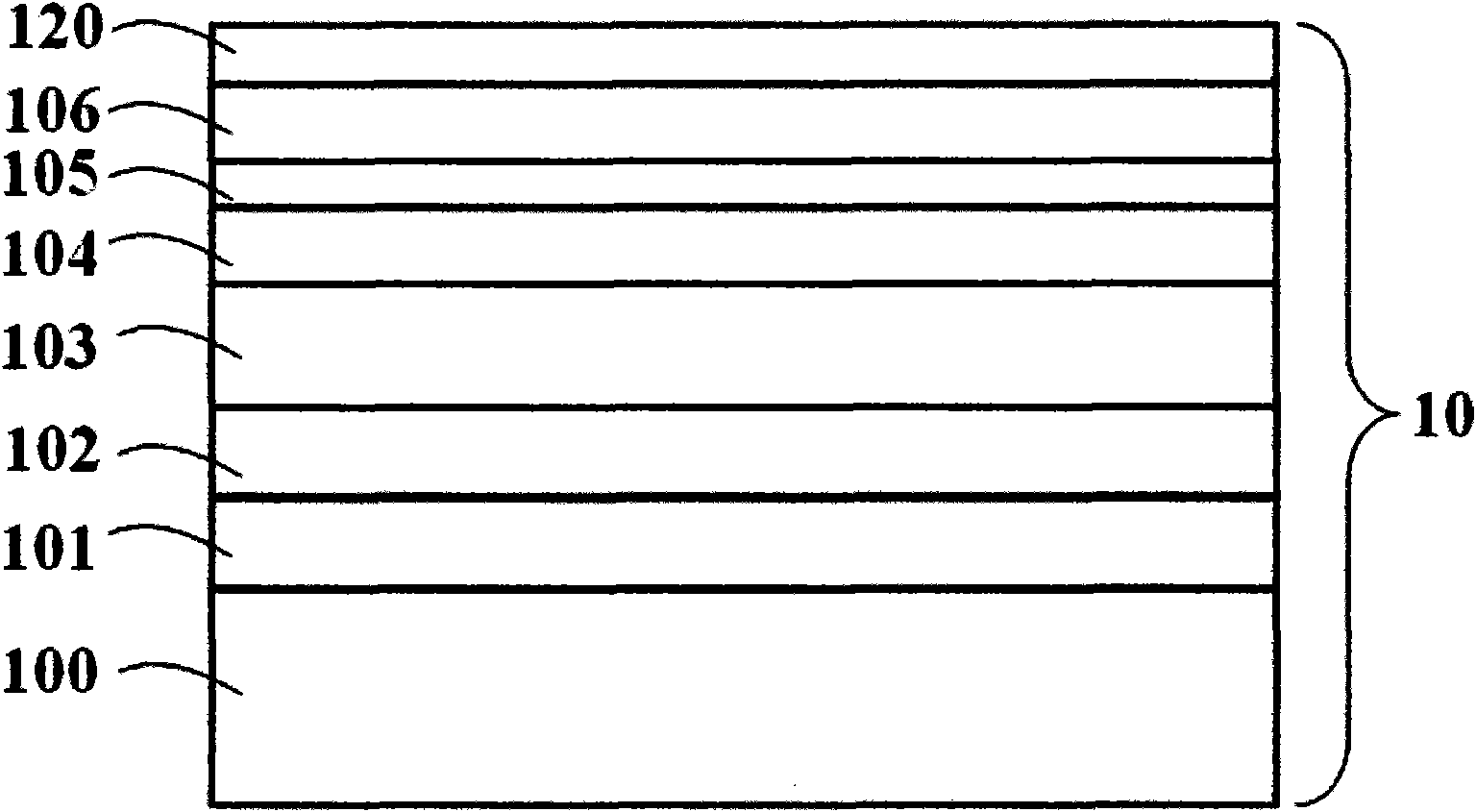

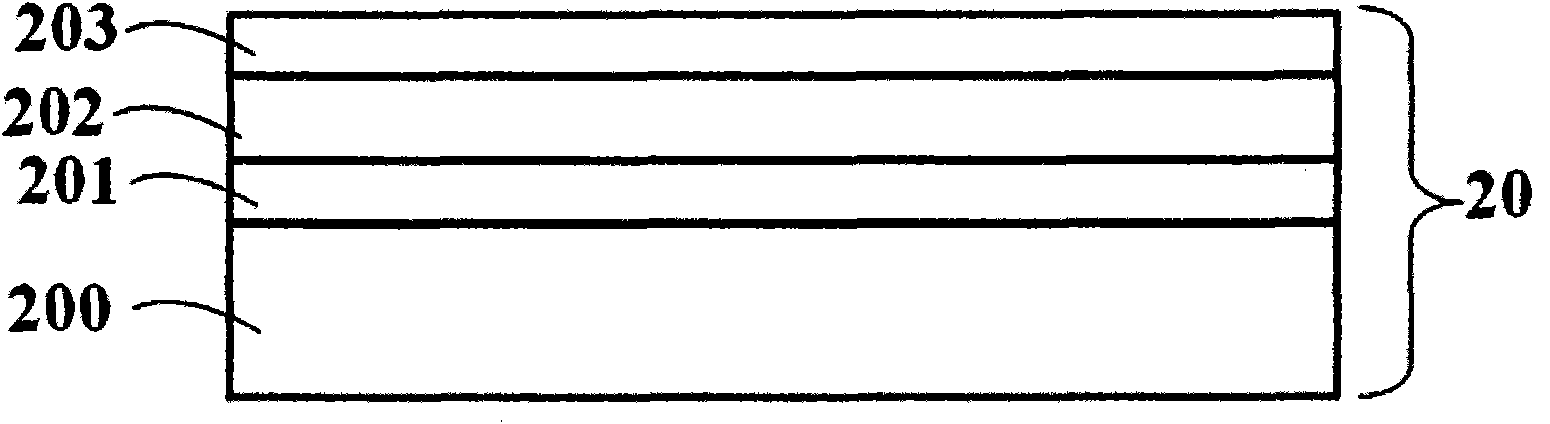

[0047] Such as figure 1 A schematic cross-sectional view of a gallium nitride-based light-emitting diode structure with an introductory roughened nitrogen polar surface shown, the structure comprising: a sapphire substrate 100; a buffer layer 101 formed on the sapphire substrate 100; a u-GaN layer 102 is formed on the buffer layer 101; the n-GaN layer 103 is formed on the buffer layer 102; the multi-quantum well active layer 104 is formed on a part of the n-GaN layer 103; the p-AlGaN confinement layer 105 is formed on On the multi-quantum well active layer 104; the p-GaN layer 106 is formed on the p-AlGaN confinement layer 105; the ITO transparent conductive layer 120 is formed on the p-GaN layer 106; the bonding layer 203 is formed on the ITO layer 120 Above part of the area, its material is In 0.2 Ga 0.8 N; the nitrogen polar surface roughened n-Ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com