Novel high-efficient energy-saving salt granulating process

A high-efficiency, energy-saving, granulation technology, applied in the direction of mold extrusion granulation, etc., can solve the problems of bulky equipment, granulation agglomeration, large space occupation, etc., to solve the problem of low molding rate, increase extrusion bulk density, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

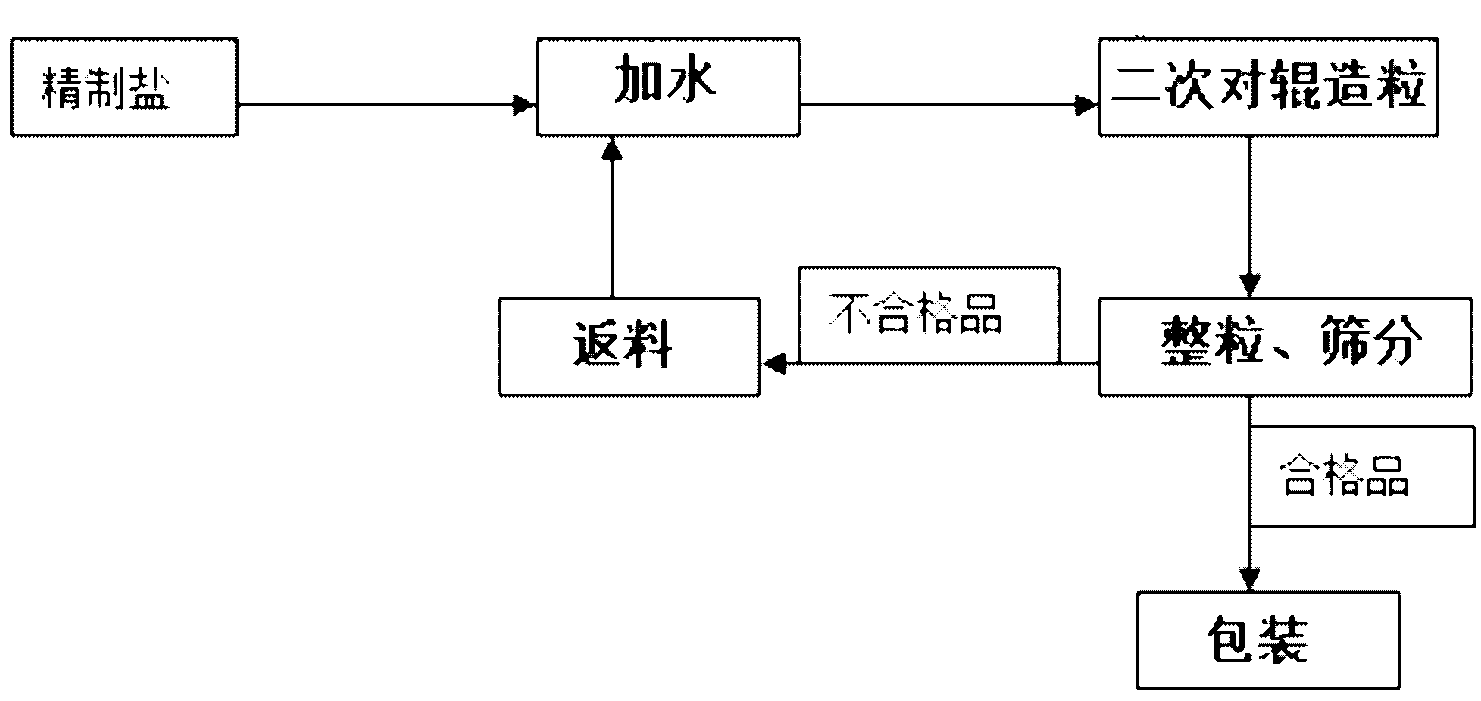

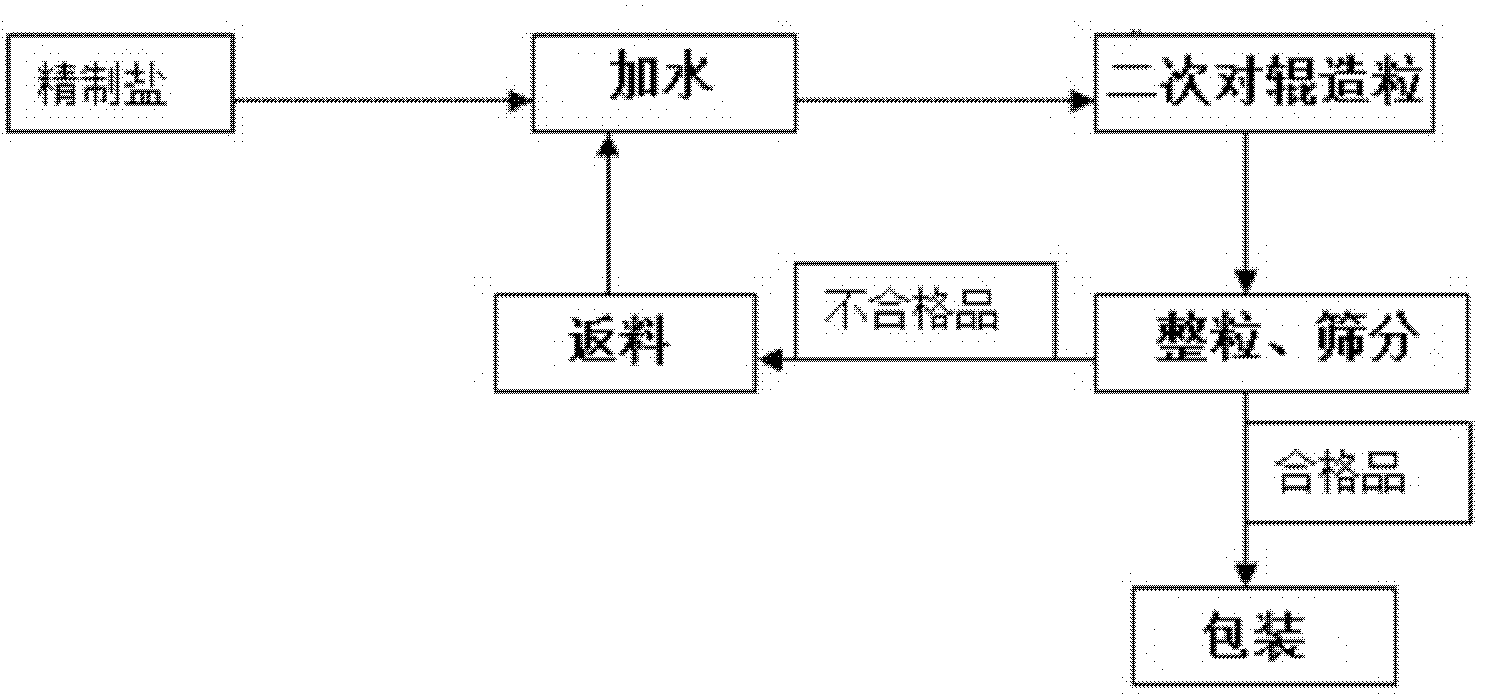

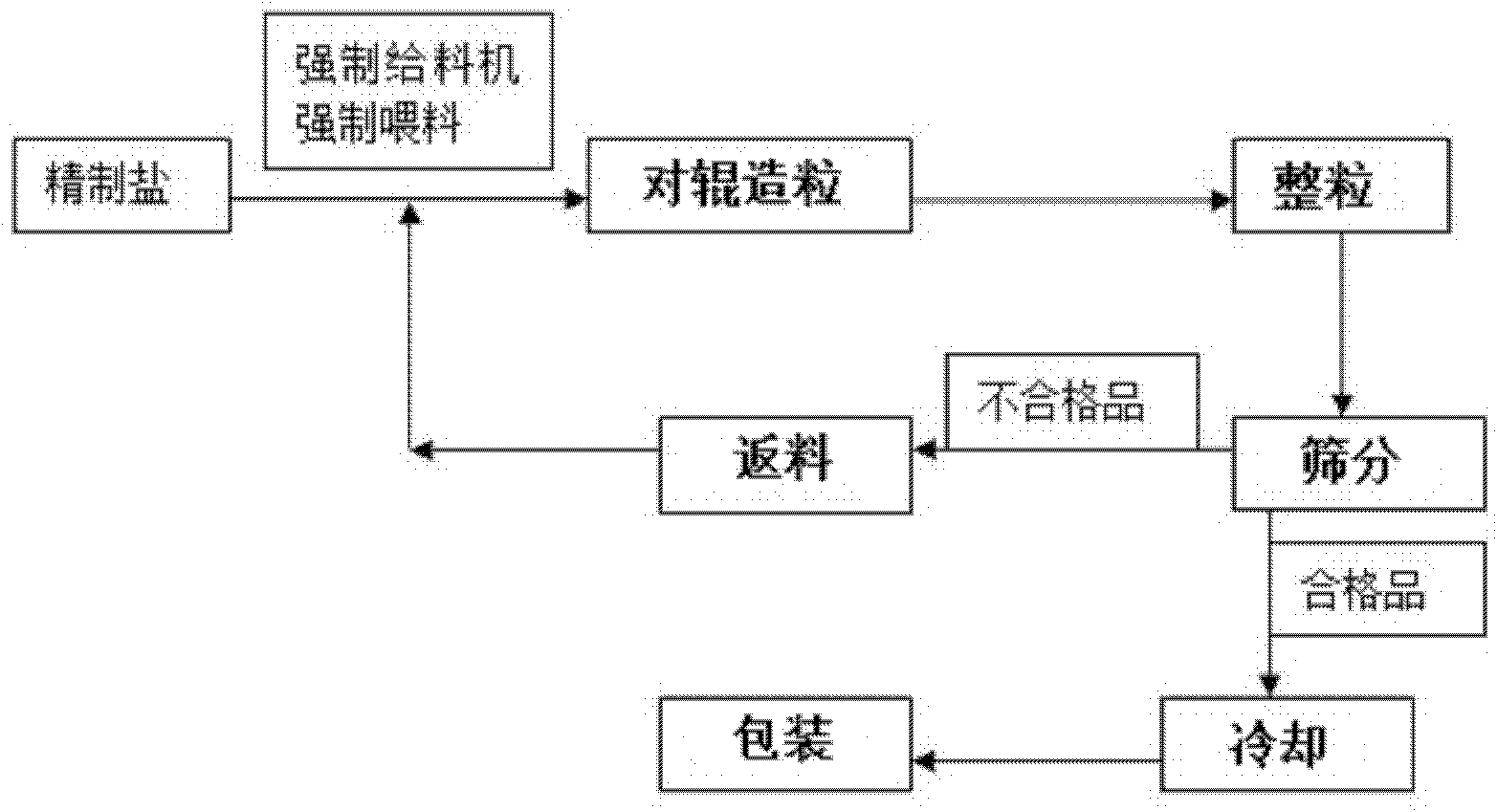

[0036] New high-efficiency and energy-saving salt granulation process

[0037] Its process flow chart is as shown in Figure 3, and its process steps are:

[0038] A. Use the water adding system to add water to the refined dry salt and mix well;

[0039] B. Carry out double-roll granulation with the double-roll granulator to add water and mix the raw material to obtain the semi-finished product;

[0040] C. Carry out granulation and screening of the semi-finished product after roller granulation;

[0041] D. For qualified products, they are packaged; for unqualified products, they are returned to the water adding system through the return system for re-granulation processing.

[0042] Among them, adding water to the raw materials is mainly through the automatic metering belt scale connected with the raw material storage tank at the top, and connected with the screw mixing conveyor at the bottom. At the outlet of the belt scale, a frequency conversion water pump is used to contr...

Embodiment 2

[0046] The raw material salt is centrifuge wet salt (with a water content of 2.4%) for vacuum salt production. No additional water is added, and other process steps remain unchanged. Finally, it is concluded that using refined centrifuge wet salt as the raw material for granulation salt granulation, the molding rate It can reach more than 85%, and the strength of the granulated salt can reach 30N on average, which shows that the wet salt of the vacuum centrifuge can also be directly used as the granulated raw material salt of the scope of the present invention.

Embodiment 3

[0048] The raw material salt still adopts the vacuum salt refining dry salt (GB5461-2000) in the embodiment 1, but the bittern used is different in nature, and the difference in calcium and magnesium content. Ultimately, it is shown that the present invention can also achieve the effect of the present invention on the refined salts produced by brines of different properties, that is to say, the present invention is applicable to the refined salts produced by brines of various properties.

[0049] For double-roll granulation, the top is connected to the outlet end of the screw mixing conveying device of the water adding system, and the outlet of the double-roll granulator is connected to the granulation screening device. One outlet of the screening device is connected to the conveying belt of qualified products, and then connected to the finished product storage barrel, and the outlet of the storage barrel is connected to the packaging machine. The other outlet of the screening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com