Catalyst for alkyl transfer and conversion of C9 and C9+ heavy aromatics to light aromatics

A heavy aromatics, transalkylation technology, applied in physical/chemical process catalysts, molecular sieve catalysts, hydrocarbons, etc., can solve the problems of low selectivity of target products, low conversion rate of heavy aromatics, and precious metals loaded on catalysts, etc. To achieve the effect of reducing aromatic ring loss, high acid site utilization, and favorable diffusion

Active Publication Date: 2010-08-25

CHINA PETROLEUM & CHEM CORP +1

View PDF9 Cites 26 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

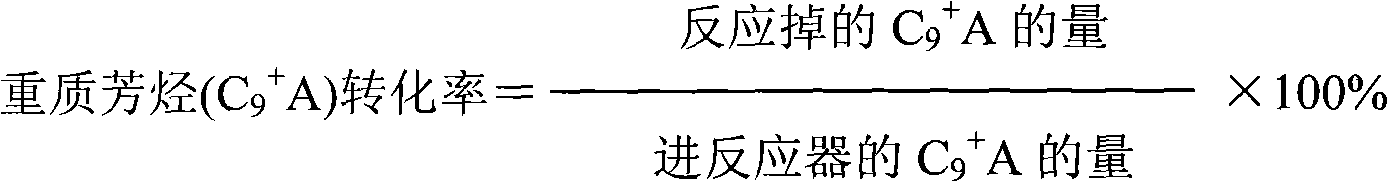

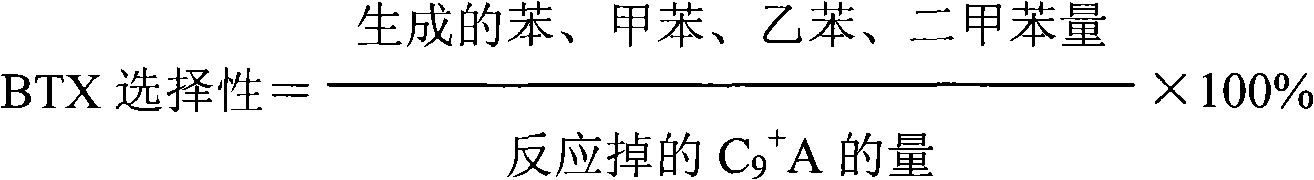

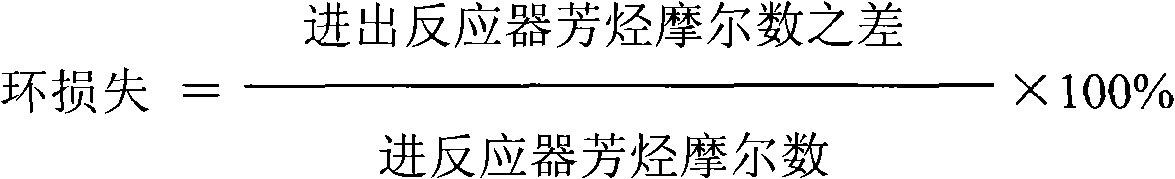

The technical problem to be solved by the present invention is to overcome the conversion rate of heavy aromatics in the prior art when benzene, toluene, and xylene are prepared by lightening and transalkylation processes using heavy aromatics with carbon nine and above as raw materials Low, low selectivity of the target product, serious ring opening of the aromatic ring, the catalyst needs to support the technical problems of noble metals, to provide a new carbon nine and above heavy aromatics lightening and transalkylation catalyst

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a catalyst for the alkyl transfer and the conversion of C9 and C9+ heavy aromatics to light aromatics, which mainly solves the existing technical problems of low heavy aromatic conversion rate, low target product selectivity, serious aromatic ring opening phenomena and catalyst requirement for noble metal loading in the process of processing C9 and C9+ heavy aromatics to increase the yield of benzene, methyl benzene and dimethyl benzene in the prior art. By adopting the technical scheme of comprising 20-90 parts of hydrogen nano zeolite and 10-80 parts of adhesive in parts by weight, wherein the mol ratio of SiO2 to Al2O3 in the hydrogen nano zeolite is 8-200, the invention well solves the problems, and can be used in industrial production for the conversion of heavy aromatics to light aromatics and the alkyl transfer.

Description

C9 and above heavy aromatics lightening and transalkylation catalyst technical field The invention relates to a catalyst for lightening and transalkylation of heavy aromatics with carbon nine and above, in particular to increasing the production of benzene and toluene through lightening and transalkylation of heavy aromatics with carbon nine and above as raw materials , Xylene, no need to support noble metal catalysts. Background technique Nanoparticles have obvious volume effect, surface effect and quantum size effect. Due to their large external specific surface area and high intracrystalline diffusion rate, nano zeolites can improve the utilization rate of catalysts, enhance the conversion capacity of macromolecules, and reduce the depth of Reaction, increased selectivity and reduced coking deactivation all showed superior performance. Heavy aromatics (or heavy aromatics) refer to the by-products of carbon nine and above aromatics in the process of petroleum and coal ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01J29/06B01J29/18B01J29/40C07C4/12C07C4/18C07C6/12

CPCY02P20/52

Inventor 祁晓岚孔德金左煜陈雪梅

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com