Online cleaning roll-type membrane bioreactor

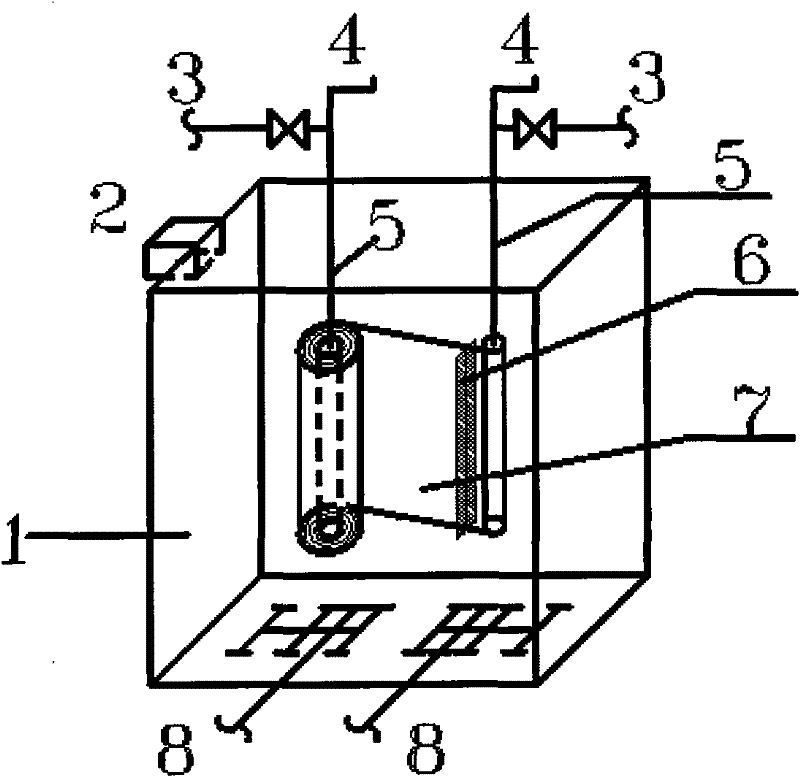

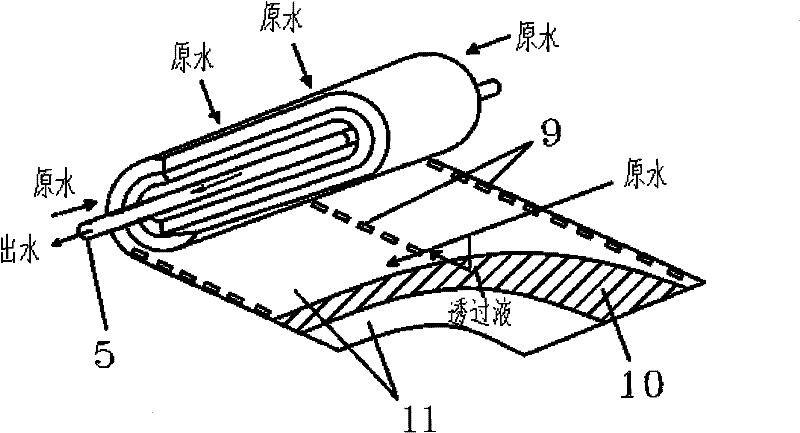

A bioreactor, rolled membrane technology, applied in sustainable biological treatment, biological water/sewage treatment, membrane technology, etc., can solve the problems of large one-time investment, low filling density, high operating energy consumption, and achieve infrastructure investment. The effect of saving, high packing density and reducing operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

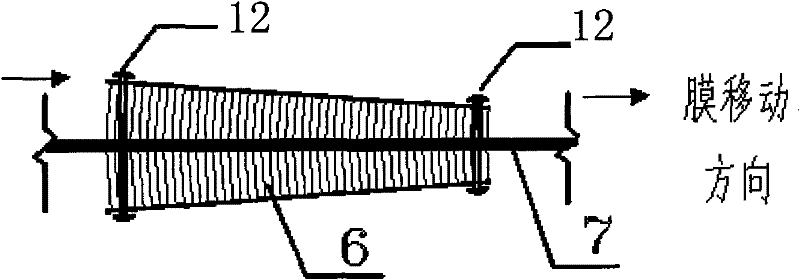

Embodiment 1

[0025] The diaphragm 7 is made of polyvinylidene fluoride (PVDF), and the mechanical cleaning device 6 is made of a brush. It was applied to the treatment of catering wastewater in a large supermarket. Reactor sludge concentration MLSS=22g / L. Membrane operating flux is 8~10L / m 2 h, after 27 days of stable operation, reach the end of the operation. The influent COD concentration is 1031±171.2mg / L, the effluent COD concentration is 79±17.2mg / L, and the average removal rate is 92.3%. After online physical cleaning, the membrane flux recovery rate can reach 59.7%.

Embodiment 2

[0027] Diaphragm 7 is made of polyethersulfone (PES), and mechanical cleaning device 6 is made of sponge. It is applied to the aerobic biological treatment of urban domestic sewage. Reactor sludge concentration MLSS=7g / L, membrane operating flux is 20L / m 2 h, after 13 days of stable operation, reach the end of the operation. The influent COD concentration is 286.0±71.2mg / L, the effluent COD concentration is 21±4.3mg / L, and the average removal rate is 92.6%. After online physical cleaning, the membrane flux recovery rate can reach 64.0%.

Embodiment 3

[0029] The diaphragm 7 is made of polyvinylidene fluoride (PVDF), and the mechanical cleaning device 6 is made of a brush. It is applied to the aerobic biological treatment of urban domestic sewage. Reactor sludge concentration MLSS=8g / L, membrane operating flux is 20L / m 2 h, after 19 days of stable operation, reach the end of the operation. The influent COD concentration is 286.0±71.2mg / L, the effluent COD concentration is 20±4.3mg / L, and the average removal rate is 93.0%. After online physical cleaning, the membrane flux recovery rate can reach 67.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com