Preparation method of mannitol

A technology of mannitol and water extraction, applied in the field of mannitol preparation, can solve the problems of low efficiency of glucose electrolysis, problem of raw material sources, poor quality of mannitol, etc., achieve good decolorization effect, low cost, and good crystallization effect Effect

Inactive Publication Date: 2010-08-25

苏州宝泽堂医药科技有限公司

View PDF1 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the prior art, mannitol is usually chemically synthesized, but there are many problems: the glucose electrolysis method has low efficiency, high energy consumption, and low purity; the products of the reduction method of polysaccharides have isomerization problems, and the cost is high and the purity is low; The source of raw materials for the sugar reduction method is problematic, etc.

The extraction method of mannitol mainly uses kelp as raw material, the quality of the obtained mannitol is poor, it is difficult to filter, and the production cost is high, so further purification is required

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a preparation method of mannitol. The technique comprises the following steps: extracting glossy privet leaf of triterpenic acid as a raw material, using 15-20 times (V / W) of deionized water to extract for 1.5-2 hours, carrying out ultrafiltration on extracting solution by an ultrafiltration membrane system with molecular weight cut off of 20000, heating and concentrating permeate till the relative density is 1.30-1.32, standing and crystallizing, using the deionized water to dissolve coarse crystal, boiling for 5 minutes, filtering with heat, recrystallizing for three times, using ether to clean, and drying at the temperature of 80-90 DEG C to obtain a product. The technique has simple operation, lower cost and higher purity and is beneficial to large-scale production operation.

Description

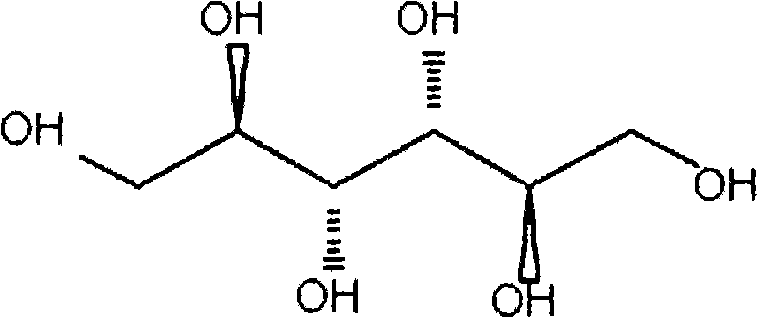

technical field The invention relates to a method for preparing mannitol, in particular to a method for extracting mannitol from privet leaf extraction residue. Background technique Mannitol, also known as D-mannitol and wood honey, is an isomer of sorbitol, both of which are hexavalent alcohols. English name: Mannitol Molecular formula: C 6 h 14 o 6 Molecular weight: 182.17 White needle crystal. The melting point is 166°C, the relative density is 1.52, 1.489 (20°C), and the boiling point is 290-295°C (467kPa). 1g of this product is soluble in about 5.5ml of water (about 18%, 25°C), 83ml of alcohol, more soluble in hot water, soluble in pyridine and aniline, and insoluble in ether. The aqueous solution is alkaline. With the chemical properties of polyols, it can be esterified, etherified, oxidized, and dehydrated. It is the only non-hygroscopic crystal among polyols. In the prior art, mannitol is usually chemically synthesized, but there are many problems: the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07C31/26C07C29/76

Inventor 李法庆张翼刘东锋

Owner 苏州宝泽堂医药科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com