Solar power generation high-strength light-weight building composite board and manufacturing method thereof

A high-intensity, solar-powered technology, applied in buildings, building components, photovoltaic power generation, etc., can solve the problems of complex installation and insufficient utilization, and achieve the effects of low cost, good light absorption, and reduced surface reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

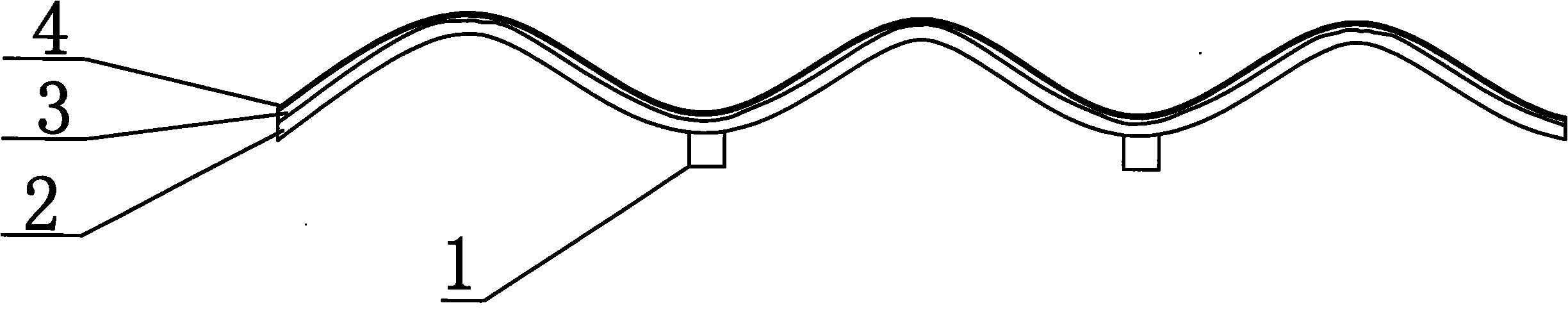

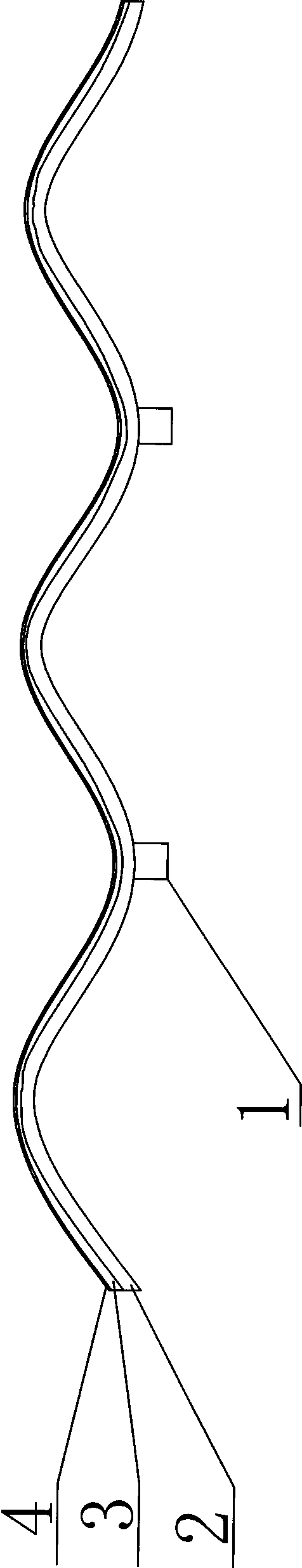

[0023] Solar power generation high-strength lightweight building composite board, its composition includes: high-strength lightweight building substrate 2, polycrystalline silicon or amorphous silicon film 3 is deposited on the high-strength lightweight building substrate, and the polycrystalline silicon or amorphous silicon There is a transparent resin film 4 on the outside of the film, and the other side of the high-strength lightweight building substrate has a lead box 1 .

Embodiment 2

[0025] The solar power generation high-strength lightweight building composite board, the composition of the high-strength lightweight building substrate includes: plant straw powder, fly ash, cement, sand, talcum powder, magnesium oxide, magnesium chloride, non-toxic viscose Mixture, modifier, 10-20 parts of plant straw powder, 10-20 parts of fly ash, 7-11 parts of cement, 5-9 parts of sand, 10-25 parts of talcum powder, 20-35 parts of magnesium oxide , 3-8 parts of magnesium chloride, 5-15 parts of non-toxic adhesive, and 0.001-1 part of modifier are poured into the mixer and mixed, then evenly poured into the mold, coated with carbon fiber mesh, and shaped by vibration rolling. Add the core tube and cover plate, add the material again and mix it evenly on the mold, after the second rolling and smoothing, transfer it to the natural curing room for 4-24 hours and then demould.

[0026] The solar power generation high-strength lightweight building composite board, the non-toxi...

Embodiment 3

[0030] A method for manufacturing a high-strength and lightweight building composite panel for solar power generation, the process of which is as follows:

[0031] (1) Make the above-mentioned high-strength light-weight building substrate: the thickness is 10mm-200mm; 10-20 parts of plant straw powder, 10-20 parts of fly ash, 7-11 parts of cement, 5-9 parts of sand, Pour 10-25 parts of talcum powder, 20-35 parts of magnesium oxide, 3-8 parts of magnesium chloride, 5-15 parts of non-toxic adhesive, and 0.001-1 part of modifier into the mixer, and then pour it into the mold evenly , add carbon fiber mesh, vibrate and roll, shape, add core tube and cover plate, add materials and mix again and evenly add to the mold, after the second rolling and smoothing, transfer to the natural curing room for 4-24 hours before demoulding ; and frosting the composite surface of the high-strength lightweight building substrate;

[0032] (2) Deposit polysilicon or amorphous silicon thin film 400-60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com