Polyamide thermal barrier strip preparation technology

A preparation process and a technology for heat insulation strips, which are applied in the field of preparation process of polyamide heat insulation strips, can solve the problems of uneven thickness, reduce production efficiency, affect uniformity and quality, etc., achieve simple preparation process, improve production efficiency, The effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

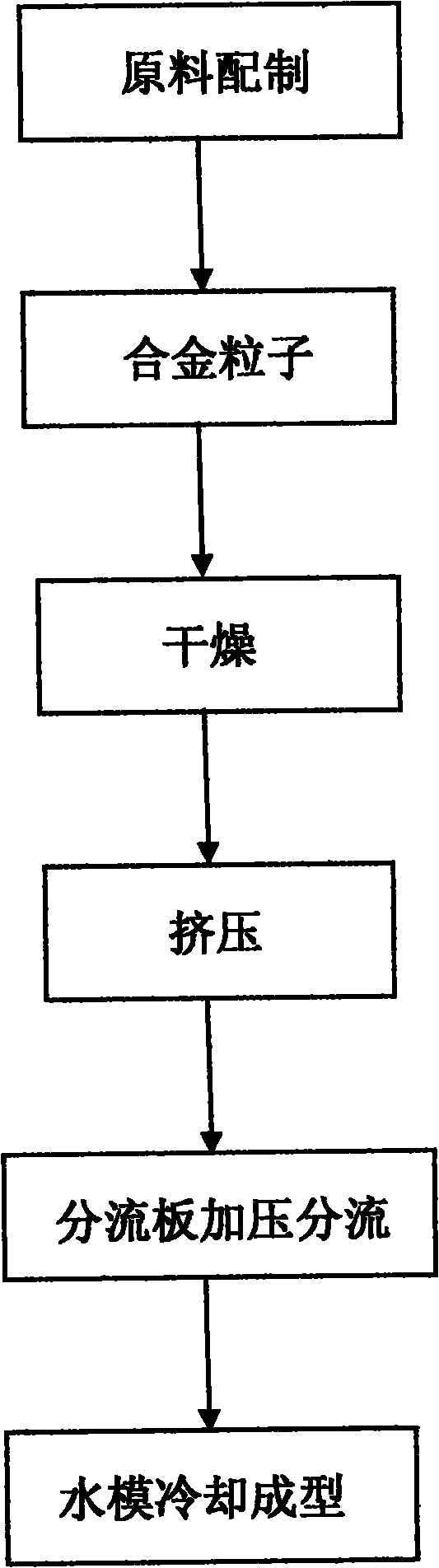

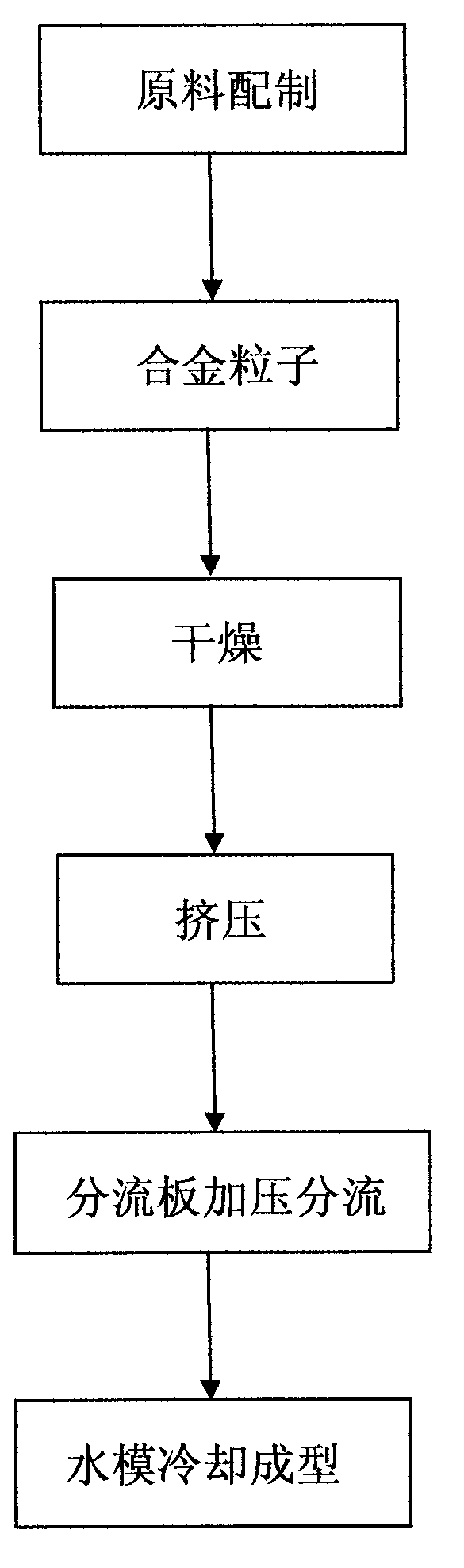

Method used

Image

Examples

Embodiment 1

[0040] Example 1: Preparation of type I polyamide heat insulation strips: raw material PA66 resin slices, glass fiber, polyolefin elastomer POE, γ-glycidyl etheroxypropyltrimethoxysilane KH560, TUF4588, and nylon chrome were weighed Preparation, by weight percentage, wherein 66 parts of PA66 resin chip, 25 parts of glass fiber, 6 parts of toughening agent, 1 part of phase solvent, 0.5 part of hydrolysis-resistant agent, 1.5 parts of nylon chrome, the prepared raw materials will be prepared in the twin-screw Mixing and refining into alloy particles in the extruder, and then use the dryer to dry the alloy particles under vacuum, use the extruder to extrude the dried alloy particles to the splitter plate, and control the melt temperature at 290 ~320°C, use a pressurizing device to pressurize the melt in the inner cavity of the manifold, use the manifold to divide the melt into two layers of 20 branches, and the matching extrusion die connected to the manifold adopts an I-shaped mo...

Embodiment 2

[0041] Example 2: Preparation of C-type polyamide heat insulation strips: raw material PA66 resin slices, glass fiber, polyolefin elastomer POE, γ-glycidyl etheroxypropyltrimethoxysilane KH560, TUF4588, and nylon chrome were weighed Preparation, by weight percentage, wherein 65 parts of PA66 resin chip, 26 parts of glass fiber, 6.5 parts of toughening agent, 1 part of phase solvent, 0.5 part of hydrolysis resistance agent, 1 part of nylon chrome, the prepared raw materials are prepared in a twin-screw The alloy particles are mixed and refined in the extruder, and then the alloy particles are dried under vacuum by the dryer, and the dried alloy particles are extruded to the diverter plate by the extruder, and the melt temperature is controlled at 290 ~320°C, use a pressurizing device to pressurize the melt in the inner cavity of the manifold, use the manifold to divide the melt into two layers of 20 branches, and the matching extrusion die connected to the manifold adopts a C-sh...

Embodiment 3

[0042]Example 3: Preparation of K-type polyamide heat insulation strips: raw material PA66 resin slices, glass fiber, polyolefin elastomer POE, γ-glycidyl etheroxypropyltrimethoxysilane KH560, TUF4588, and nylon chrome were weighed Preparation, in terms of weight percentage, wherein 65 parts of PA66 resin chip, 25 parts of glass fiber, 6.5 parts of toughening agent, 1.5 parts of phase solvent, 0.5 part of hydrolysis resistance agent, 1.5 parts of nylon chrome, the prepared raw materials will be prepared in the twin-screw Mixing and refining into alloy particles in the extruder, and then use the dryer to dry the alloy particles under vacuum, use the extruder to extrude the dried alloy particles to the splitter plate, and control the melt temperature at 290 ~320°C, use a pressurizing device to pressurize the melt in the inner cavity of the manifold, use the manifold to divide the melt into two layers of 20 branches, and the matching extrusion die connected to the manifold adopts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com