High-volume and capacity ratio spherical lithium ferric phosphate and preparation method thereof

A technology of lithium iron phosphate and specific capacity, which is applied in the field of lithium-ion battery cathode materials and its preparation, can solve the problems of low tap density, low volume specific capacity, and low electronic conductivity, and achieve the effect of preventing rapid growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

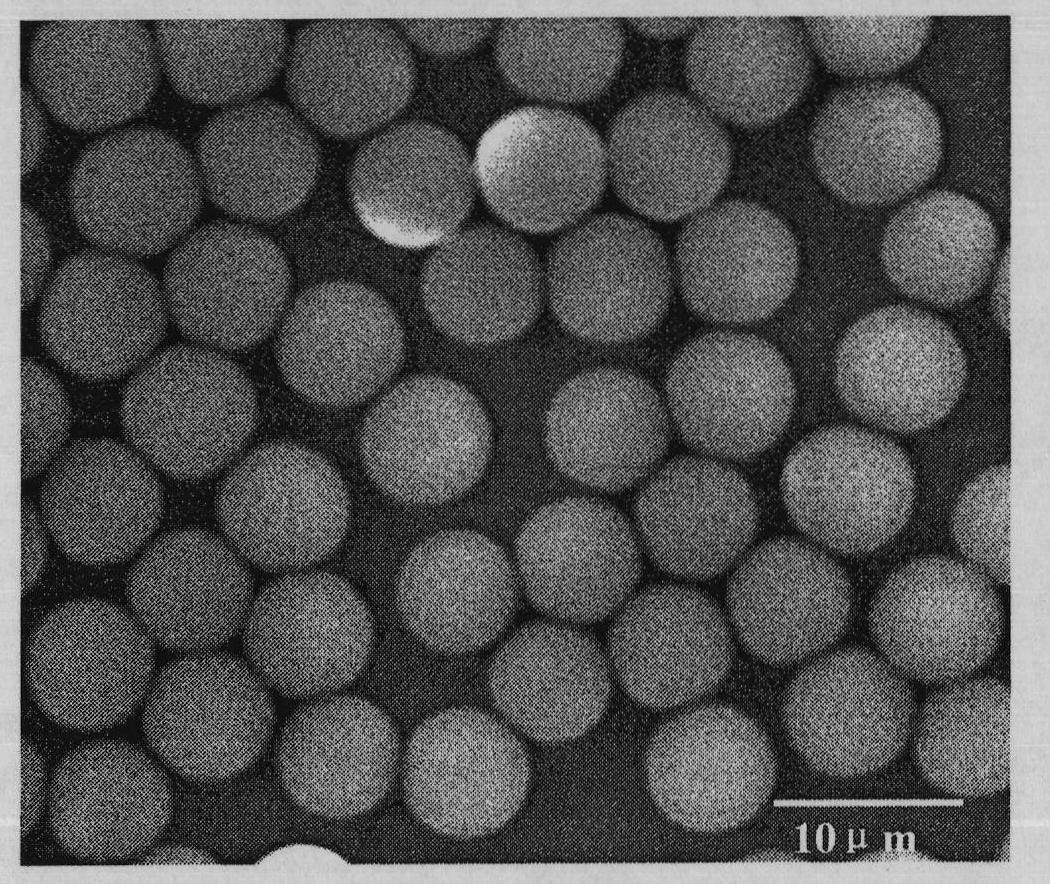

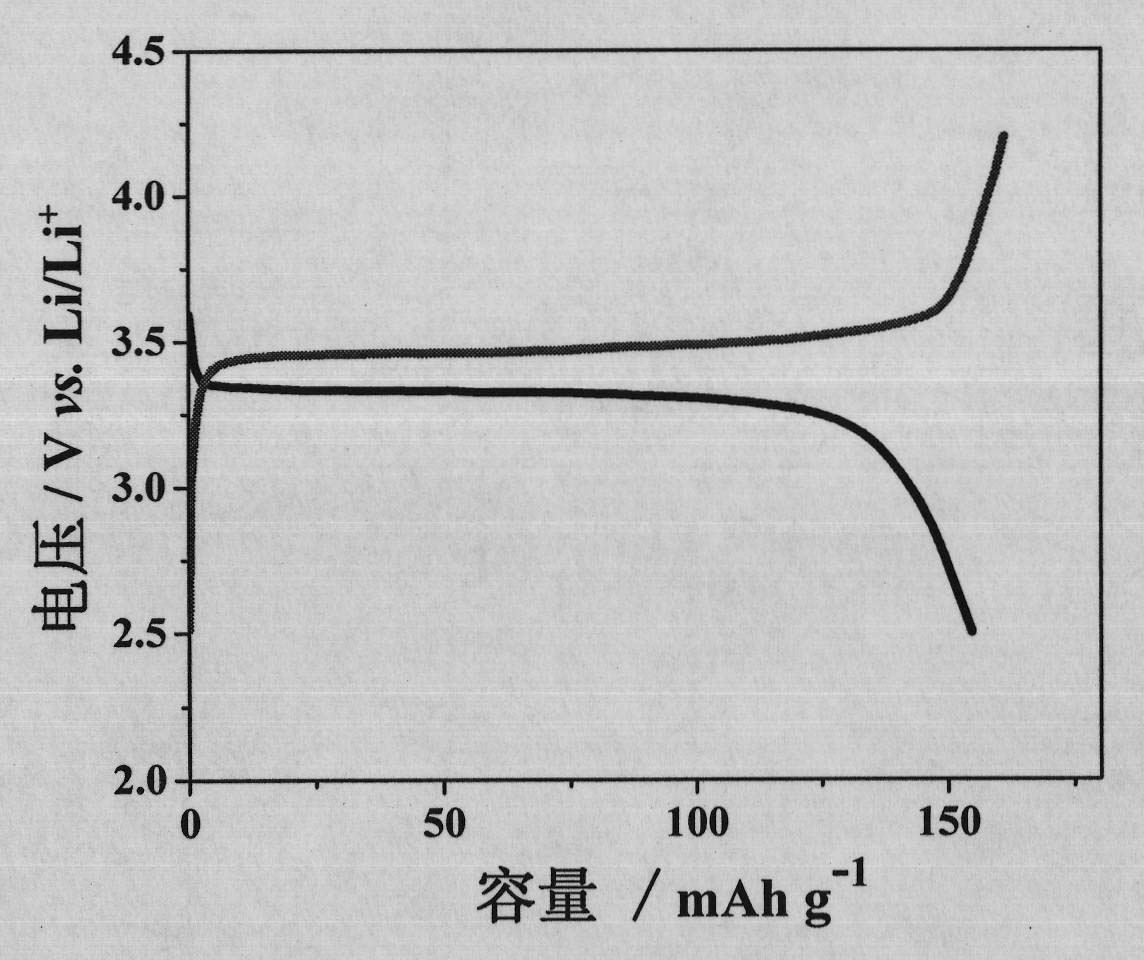

[0024] 0.21 g of LiOH·H 2 O was added to the prepared 0.5mol / L HNO 3 Dissolve in the solution, then add 1.11 g of FePO 4 4H 2 O and 0.44 g vitamin C, stir the solution and mix well. use NH 3 The water was adjusted to just precipitate (pH = 7). Then the solution was put into a microwave oven, and the solvent was evaporated to dryness by alternately heating for 5 seconds and intermittently for 5 seconds to obtain a yellow powder. Grind the obtained yellow powder into fine particles, put it into a porcelain boat, put it into a high-temperature furnace, and raise the temperature to 700°C at a rate of 5°C / min in a high-purity nitrogen atmosphere, and keep it warm for 6 hours to obtain a spherical lithium iron phosphate sample. The tap density is 2g / cm 3 . XRD test shows pure lithium iron phosphate with olive structure. The topography of the sample and the first charge-discharge curve at 0.1C are shown in figure 1 and figure 2 middle. Such as figure 1 As shown, the obta...

Embodiment 2

[0026] Weigh out 0.52 g of CH 3 COOLi·2H 2 O was added to the prepared 0.5mol / L HNO 3 Dissolve in the solution, then add 1.11 g of FePO 4 4H 2 O and 0.44 g vitamin C, stir the solution and mix well. use NH 3 The water was adjusted to just precipitate (pH = 7). Then the solution was put into a microwave oven, and the solvent was evaporated to dryness by alternately heating for 5 seconds and intermittently for 30 seconds to obtain a yellow powder. Grind the obtained yellow powder into fine particles, put it into a porcelain boat, put it into a high-temperature furnace, and raise the temperature to 700°C at a rate of 5°C / min in a high-purity nitrogen atmosphere, and keep it warm for 6 hours to obtain a spherical lithium iron phosphate sample. The tap density is 1.7g / cm 3 .

Embodiment 3

[0028] 0.19 g of Li 2 CO 3 Add prepared 0.5mol / L HNO 3 Dissolve in the solution, then add 1.11 g of FePO 4 4H2 O and 0.44 g vitamin C, stir the solution and mix well. use NH 3 The water was adjusted to just precipitate (pH = 7). Then the solution was put into a microwave oven, and the solvent was evaporated to dryness by alternately heating for 10 seconds and intermittently for 30 seconds to obtain a yellow powder. Grind the obtained yellow powder into fine particles, put it into a porcelain boat, put it into a high-temperature furnace, and raise the temperature to 700°C at a rate of 5°C / min in a high-purity nitrogen atmosphere, and keep it warm for 6 hours to obtain a spherical lithium iron phosphate sample. The tap density is 1.7g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com