Hypovanadic oxide-based composite film with adjustable radiance and preparation method thereof

A vanadium dioxide and composite thin film technology, applied in sputtering coating, vacuum evaporation coating, coating and other directions, can solve the problems of high emissivity at low temperature, excessive radiation heat dissipation, unfavorable heat preservation, etc. The effect of expanding the application range and suppressing the radiative heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1) Depositing a vanadium dioxide film on a transparent substrate: depositing a vanadium dioxide film with a thickness of 40 nanometers on a transparent substrate.

[0045] 2) deposition of conductive metal film by sputtering;

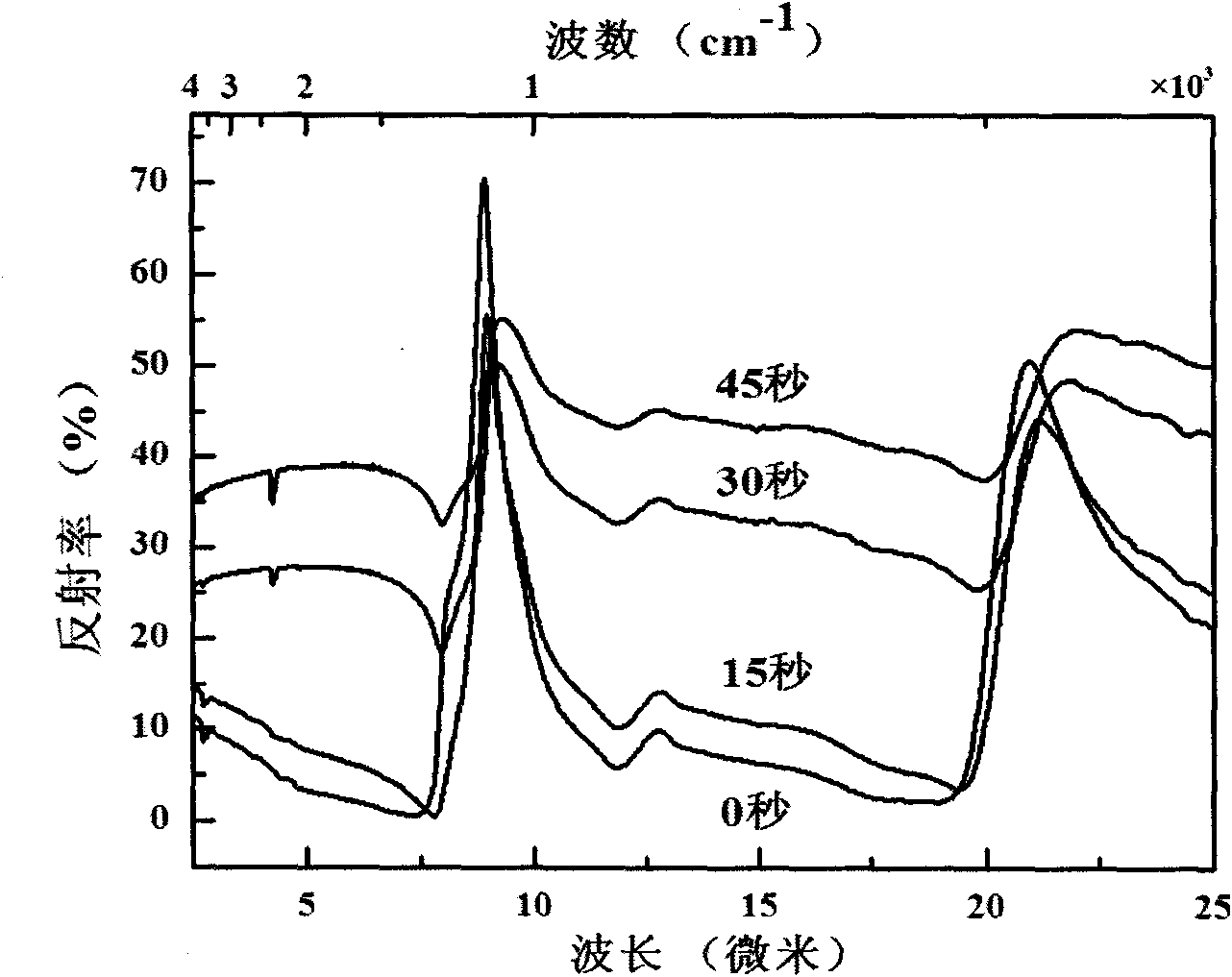

[0046] Preparation of conductive metal film: place a quartz substrate deposited with a 40-nanometer-thick vanadium dioxide film in a sputtering chamber, vacuumize to 8.0 Pa, use a platinum metal material with a weight percentage of 99.5% as a target, and work in an atmosphere of It is high-purity argon gas, and the argon gas is injected into the sputtering chamber at a flow rate of 30 sccm and the pressure is maintained at 8.0 Pa, the sputtering current is set at 30 mA, and the sputtering time is 30 seconds to obtain a vanadium dioxide-based composite film, in which the conductive metal The thickness of the film was 13 nm.

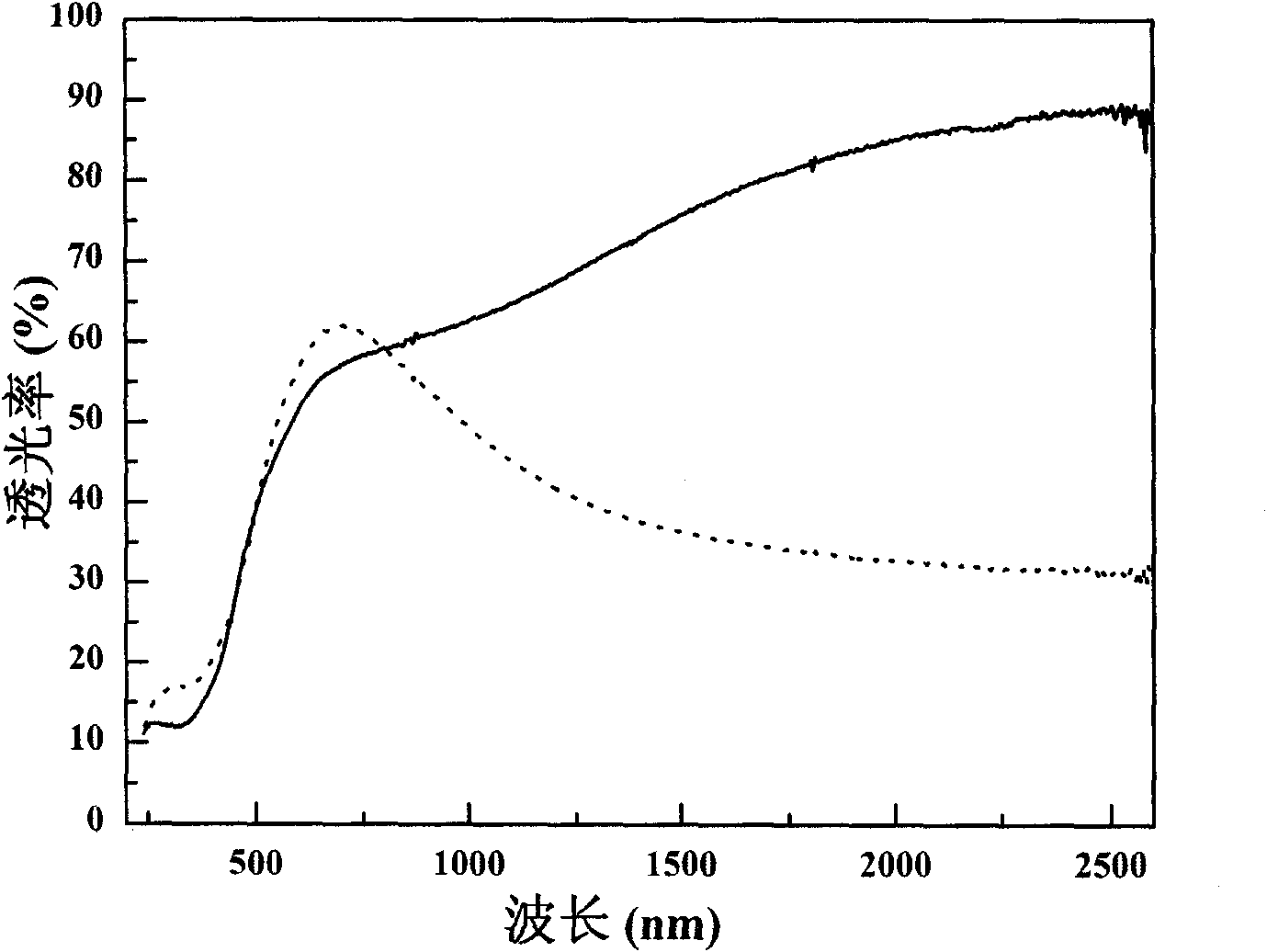

[0047] Utilize the international standard GB / T 2680-94 measurement to know that the emissivity of gained vanadium dioxide-...

Embodiment 2

[0050] 1) Depositing a vanadium dioxide film on a transparent substrate: depositing a vanadium dioxide film with a thickness of 40 nanometers on a transparent substrate.

[0051] 2) deposition of conductive metal film by sputtering;

[0052] Preparation of conductive metal film: place a quartz substrate deposited with a 40-nanometer-thick vanadium dioxide film in a sputtering chamber, vacuumize to 8.0 Pa, use a platinum metal material with a weight percentage of 99.5% as a target, and work in an atmosphere of It is high-purity argon gas, the argon gas is injected into the sputtering chamber at a flow rate of 30 sccm and the air pressure is maintained at 8.0 Pa, the sputtering current is set at 30 mA, and the sputtering time is 15 seconds to obtain a vanadium dioxide-based composite film, in which the conductive metal The thickness of the film is 6 nm.

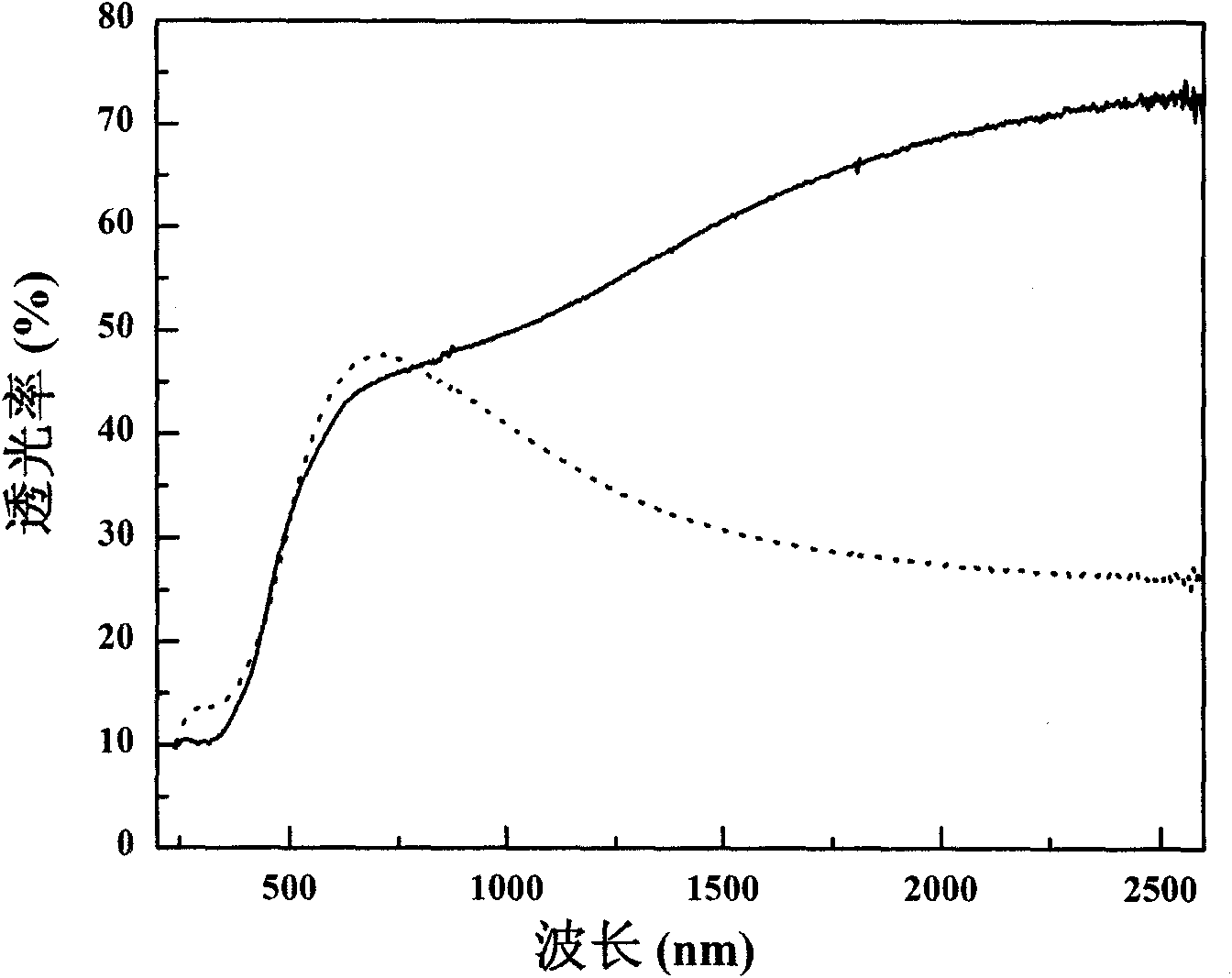

[0053] According to the measurement of the international standard GB / T 2680-94, it can be seen that the emissivity of the ob...

Embodiment 3

[0056] 1) Depositing a vanadium dioxide film on a transparent substrate: depositing a vanadium dioxide film with a thickness of 40 nanometers on a transparent substrate.

[0057] 2) deposition of conductive metal film by sputtering;

[0058] Preparation of conductive metal film: place a quartz substrate deposited with a 40-nanometer-thick vanadium dioxide film in a sputtering chamber, vacuumize to 8.0 Pa, use a platinum metal material with a weight percentage of 99.5% as a target, and work in an atmosphere of It is high-purity argon gas, and the argon gas is injected into the sputtering chamber at a flow rate of 30 sccm and the pressure is maintained at 8.0 Pa. The sputtering current is set at 30 mA, and the sputtering time is 45 seconds to obtain a vanadium dioxide-based composite film, in which the conductive metal film The thickness is 18 nm. According to the measurement of the international standard GB / T 2680-94, it can be seen that the emissivity of the obtained vanadium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com