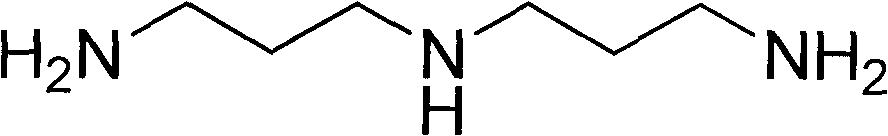

Preparation method of N-(3-aminopropyl)-1,3-propane diamine

A technology of aminopropyl and propylenediamine, which is applied to the preparation of amino compounds, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of high energy consumption, poor selectivity, and low yield, and achieve simple process and three wastes The effect of less and lower cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

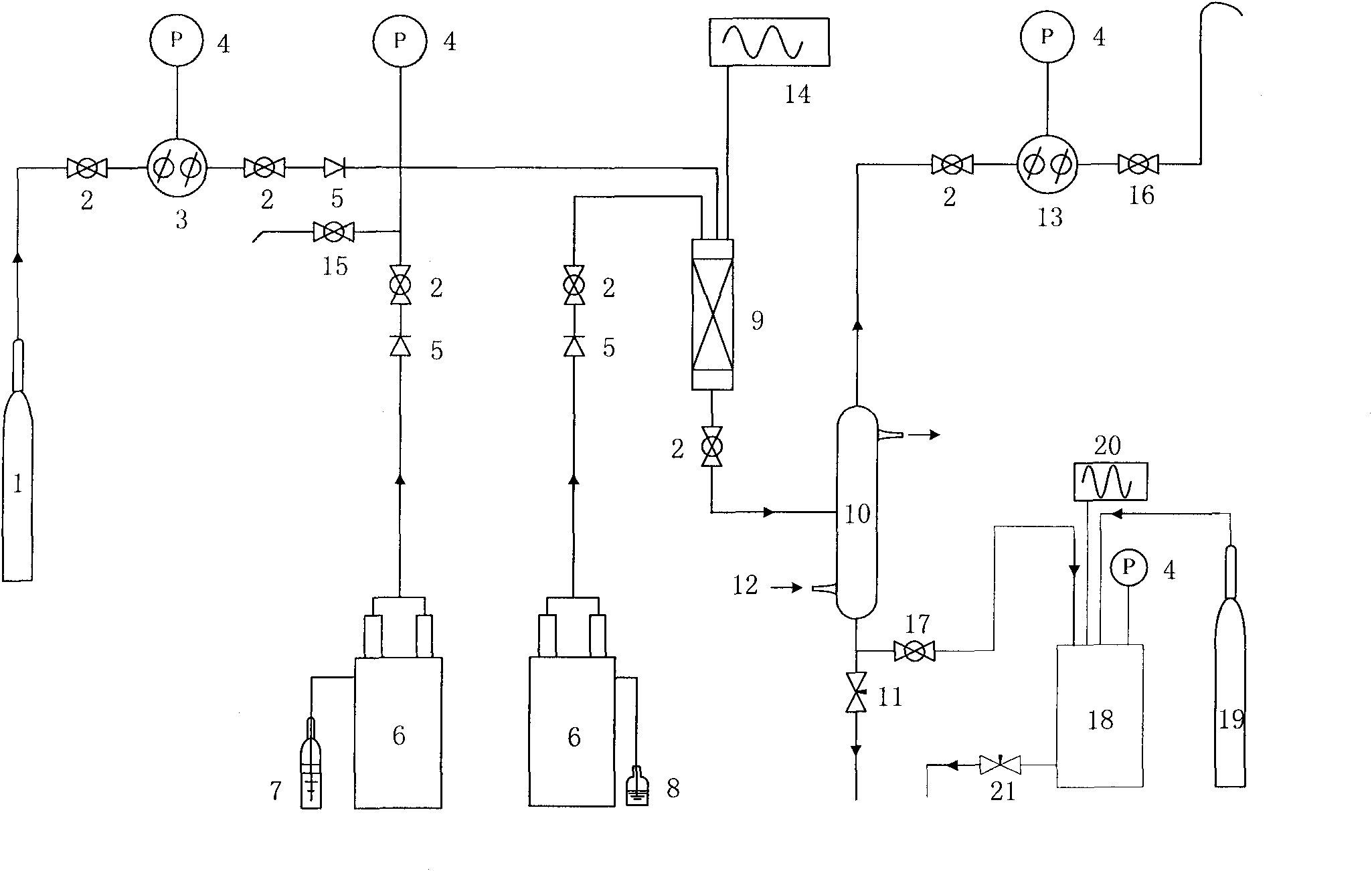

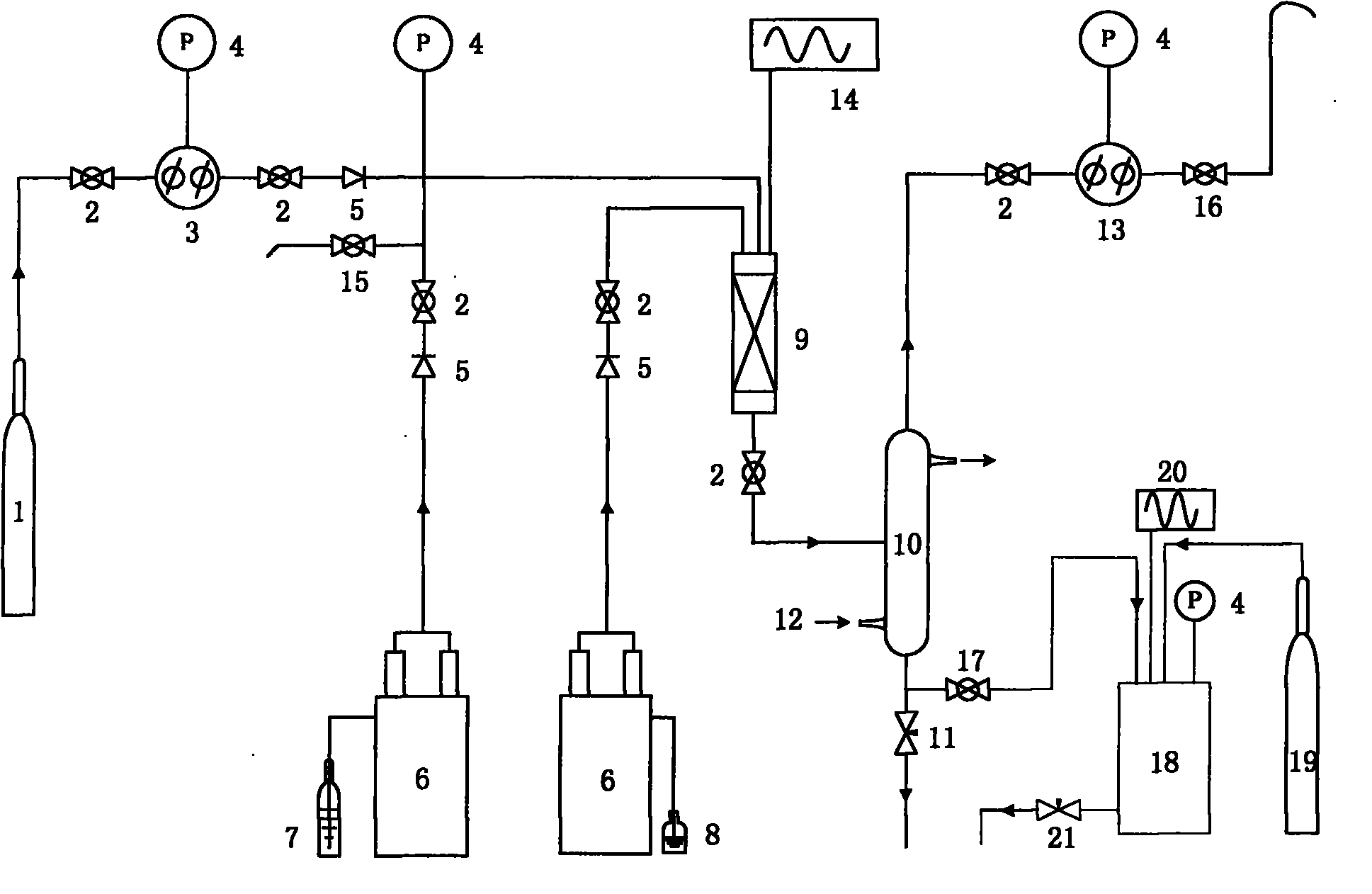

[0015] Close the first needle valve 11, the raw material vent valve 15, the second ball valve 16 and the third ball valve 17, open the constant pressure valve 3, the pressure valve 13 and all the first ball valves 2, and the reactor 9 is filled with 3A spherical molecular sieves, Use nitrogen to set the pressure of the constant pressure valve 3 and the pressure valve 13 to 5 MPa, then close 3 and 13, open the second ball valve 16, use the first temperature controller 14 to control the temperature of the reactor 9 to 50 ° C, and open the condensation at the same time water12. After the temperature and pressure are stabilized, use metering pump 6 to mix liquid ammonia and acrylonitrile with a molar ratio of 1.5:1 and a total volume space velocity of 0.5h -1 At the same time, it is sent into the reactor 9, and the first needle valve 11 is adjusted to control the pressure of the reaction system to be about 5MPa. After the device was running for 5 hours, a small amount of reaction...

Embodiment 2

[0017] Close the first needle valve 11, the raw material vent valve 15, the second ball valve 16 and the third ball valve 17, open the constant pressure valve 3, the pressure valve 13 and all the first ball valves 2, and the reactor 9 is filled with 3A spherical molecular sieves, Use nitrogen to set the pressure of the constant pressure valve 3 and the pressure valve 13 to 4MPa, then close 3 and 13, open the second ball valve 16, use the first temperature controller 14 to control the temperature of the reactor 9 to be 80°C, and open the condensation at the same time water12. After the temperature and pressure are stabilized, use metering pump 6 to mix liquid ammonia and acrylonitrile with a molar ratio of 1:1 and a total volume space velocity of 0.5h -1 At the same time, it is sent into the reactor 9, and the first needle valve 11 is adjusted to control the pressure of the reaction system to be about 4MPa. After the device was running for 5 hours, a small amount of reaction l...

Embodiment 3

[0019] Close the first needle valve 11, the raw material vent valve 15, the second ball valve 16 and the third ball valve 17, open the constant pressure valve 3, the pressure valve 13 and all the first ball valves 2, and the reactor 9 is filled with 5A spherical molecular sieves, Use nitrogen to set the pressure of the constant pressure valve 3 and the pressure valve 13 to 5 MPa, then close 3 and 13, open the second ball valve 16, use the first temperature controller 14 to control the temperature of the reactor 9 to be 15 °C, and open the condensation at the same time water12. After the temperature and pressure are stabilized, use metering pump 6 to mix liquid ammonia and acrylonitrile with a molar ratio of 5:1 and a total volume space velocity of 0.8h -1 At the same time, it is sent into the reactor 9, and the first needle valve 11 is adjusted to control the pressure of the reaction system to be about 5MPa. After the device was running for 3 hours, a small amount of reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com