Method for preparing magnesium chloride loaded late transition metal catalyst

A late-transition metal and magnesium chloride technology, which is applied in the field of preparation of magnesium chloride-supported post-transition metal catalysts, can solve problems such as uncontrollable, complicated carrier preparation, and poor particle shape of the carrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

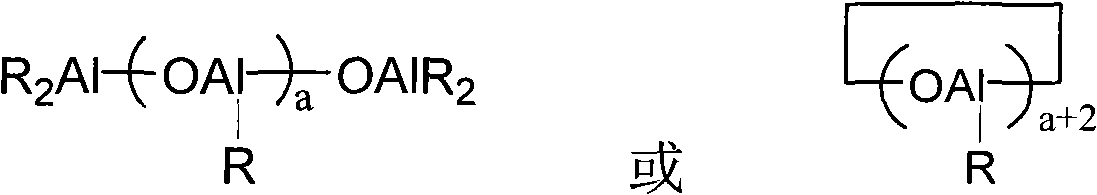

Method used

Image

Examples

Embodiment 1

[0048] Under nitrogen protection, in a glass reactor, add 25.21 grams of anhydrous magnesium chloride at room temperature, then add 700 milliliters of dried THF, start stirring, raise the temperature to 65 ° C, stir and dissolve for 5 hours to ensure that the magnesium chloride is completely dissolved, and then pass through Buchi B -290 spray dryer prepares spherical magnesium chloride / tetrahydrofuran particles, the content of tetrahydrofuran is 23wt%, and the particle size is D 50 is 16 microns.

[0049] Spherical magnesium chloride / tetrahydrofuran particles were vacuum-dried at 100°C for 2 hours, and then vacuum-dried at 300°C for 10 hours to obtain a spherical magnesium chloride carrier with good fluidity. No tetrahydrofuran was detected by gas chromatography analysis.

[0050] Under the protection of nitrogen, take 4.61 grams of the magnesium chloride carrier obtained above and add it to a glass reactor, add 60 milliliters of dried toluene, disperse into a suspension, add ...

Embodiment 2

[0054] Spherical MgCl / THF particles were prepared on a pilot plant.

[0055] Under the protection of nitrogen, in the reactor, add 7.2 kg of anhydrous magnesium chloride at room temperature, then add 200 liters of dried tetrahydrofuran, start stirring, raise the temperature to 65 ° C, stir and dissolve for 7 hours to ensure that the magnesium chloride is completely dissolved, and then spray through the pilot test Dryer (3 kg carrier capacity per hour) prepared spherical magnesium chloride / tetrahydrofuran particles, tetrahydrofuran content 31wt%, particle size D 50 is 26 microns.

[0056] 200 grams of spherical magnesium chloride / tetrahydrofuran particles were vacuum-dried at 100° C. for 2 hours, and then vacuum-dried at 300° C. for 10 hours to obtain a magnesium chloride carrier with good fluidity. Through gas chromatography analysis, no tetrahydrofuran was detected.

[0057] Under the protection of nitrogen, take 4.83 grams of the magnesium chloride carrier obtained above an...

Embodiment 3

[0060] Under the protection of nitrogen, take 3.74 grams of the magnesium chloride carrier obtained in Example 3 and add it to a glass reactor, add 60 milliliters of dried toluene, disperse into a suspension, add 21 milliliters of 10 wt% MAO (methylaluminoxane) toluene The solution was heated to 50° C., stirred and reacted for 4 hours, then washed three times with 50 ml × 3 toluene, then washed with hexane, and dried in vacuum to obtain a solid powder with good fluidity, that is, a magnesium chloride carrier containing methylaluminoxane.

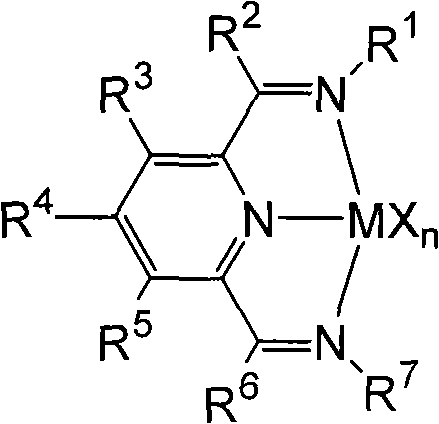

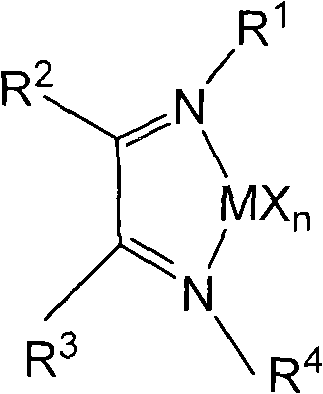

[0061] Under the protection of nitrogen, 2.25 grams of the magnesium chloride carrier containing methylaluminoxane obtained above was added to a glass reactor, and 35 milliliters of dried toluene was added to make a slurry, and 0.175 grams of Ni catalyst dissolved in 20 milliliters of toluene The solution of the precursor (2,3-bis(2,6-diisopropylphenylimine) butane nickel dibromide, see the structure below) was added dropwise into the reactor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com