Sulfoacid rare earth catalyst for polymerizing high-cis-isoprene rubber and preparation method thereof

A technology of isoprene rubber and rare earth catalyst, which is applied in the field of sulfonic acid rare earth catalyst, can solve the problems of long polymerization time and low catalytic efficiency, and achieve the effects of shortened polymerization time, simple preparation process and high molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

[0021] Embodiment 1-10: Neodymium benzenesulfonate / alcohol complex rare earth catalyst and its preparation method

Embodiment 1

[0022] Embodiment 1: Neodymium benzenesulfonate / ethanol complex rare earth catalyst and its preparation method

[0023] (1) Composition of neodymium benzenesulfonate / ethanol complex rare earth catalyst: the binary rare earth catalyst is composed of neodymium benzenesulfonate / ethanol complex and triisobutylaluminum; triisobutylaluminum and neodymium benzenesulfonate / ethanol The molar ratio of rare earth neodymium in the complex is 20:1.

[0024] (2) The method for preparing the rare earth catalyst of neodymium benzenesulfonate / ethanol complex: under the protection of nitrogen, in the catalyst preparation device through drying, add 1.0×10 -4 mol of neodymium benzenesulfonate / ethanol complex shown in Table 1 and 2.0×10 -3 mol triisobutylaluminum, the mol ratio of triisobutylaluminum to neodymium benzenesulfonate / ethanol complex is 20:1, after aging for 30 minutes at 60°C, the concentration obtained is 1.96×10 -4 mol / mL neodymium benzenesulfonate rare earth catalyst for the poly...

Embodiment 2-10

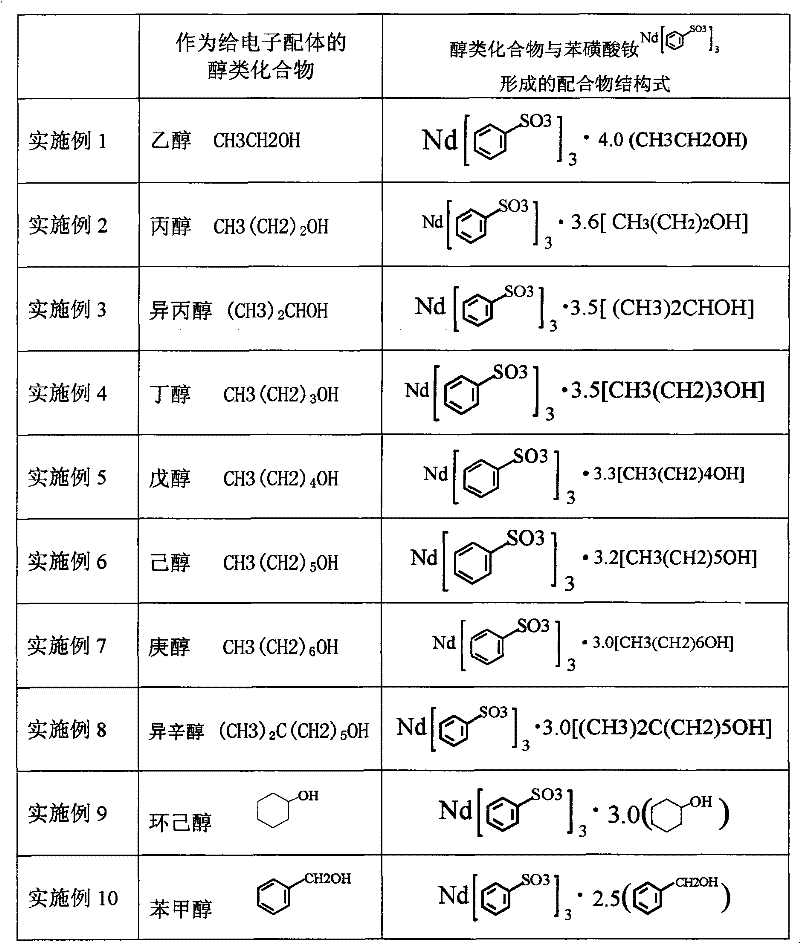

[0025] Embodiment 2-10: other conditions are the same as embodiment 1, only the neodymium benzenesulfonate / alcohol complex in embodiment 1 is changed into other neodymium benzenesulfonate / alcohol as shown in table 1 in embodiment 2-10 Class complexes.

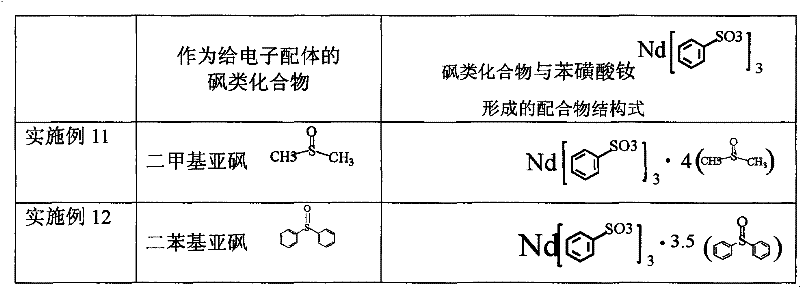

[0026] Table 1 Alcohol compounds and neodymium benzenesulfonate as electron-donating ligands Formed complex structure

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com