Technique for producing terphenyl, indane and aromatics solvent oil by cracking C9 fraction and hydrogenation

A technology for aromatic solvent oil and distillate, which is applied in the fields of hydrotreating process, hydrocarbon oil treatment, hydrogenation hydrocarbon production, etc. It can solve the problems of low comprehensive utilization rate and waste of resources, etc., and achieve the improvement of aromatic hydrocarbon retention rate, avoid waste, and increase economy benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The cracking C9 raw material property that present embodiment adopts sees the following table:

[0039] Cracked C9 Fraction Composition

data

Aromatics, (% mass)

58~62

n-alkanes, (% mass)

1.1~1.2

Isoparaffins, (% mass)

30~31

Naphthenes, (% mass)

1~2

Monoolefins, (% mass)

28~30

Total sulfur, ppm

150~180

Total nitrogen, ppm

50~65

Colloid, mg / 100g

<500

Bromine value, gBr / 100g

95

Diolefins, (% mass)

1~4

[0040] Cracked C9 Fraction Composition

data

Density, 20℃, g / ml

0.8921~0.895

Distillation range, ℃

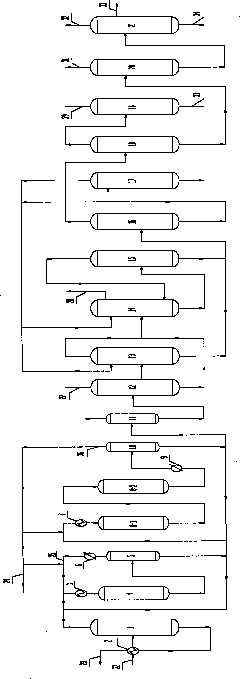

Initial boiling point ~ 230

[0041] Specific process such as figure 1 Shown:

[0042] (1) Raw material pretreatment part: the cracked C9 raw material 22 first enters the heat exchanger 2 to exchange heat with the degumming tower bottom oil 23, and then enters the degumming tower 1 for degumming, ...

Embodiment 2

[0053] The cracking C9 raw material used in this example is the same as that in Example 1.

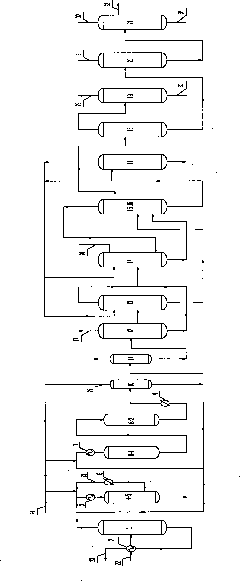

[0054] Such as figure 2 As shown, the one-stage hydrogenation reactor 4 and the gas-liquid separator 5 in this embodiment can be combined into one to form a two-in-one reactor 4-5, and the lower section of the reactor 4-5 is provided with a gas-liquid separation space; The stripping tower 15 and the solvent recovery tower 16 can be combined into one to form a stripping solvent recovery tower 15-16, which can reduce equipment investment and equipment investment.

[0055] Specific process flow:

[0056] (1) Raw material pretreatment part: Cracking C9 raw material 22 first enters heat exchanger 2 to exchange heat with degumming tower bottom oil 23, then enters degumming tower 1 for degumming, and the fraction <230°C is obtained at the top of the tower, and the tower bottom oil 23 exchanges heat with cracking C9 raw material 22 and exits the device.

[0057] (2) Hydrogenation part: the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com