Dexibuprofen particle and preparation method thereof

A granule and sodium carbonate technology, which is applied in the direction of pharmaceutical formulas, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve the problem of long time required for low-temperature drying, unqualified microbial limits, and difficult moisture control and other problems, to achieve the effect of stable and controllable quality, suitable for industrial production, and easy control of microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Pass the dextrobuprofen, sodium carbonate, and aspartam through 80-mesh sieves respectively, and sucrose after crushing and pass through 80-mesh sieves for later use.

[0043] Weigh the raw materials of the following prescription quantities:

[0044] Dexibuprofen 200g

[0046] Sucrose 2480g

[0047] Aspartame 60g

[0048] 75% ethanol 860g

[0049] Lychee essence 10g.

[0050] Fully mix aspartam, dextrobuprofen, and sodium carbonate to obtain a mixture. Divide sucrose into 3 parts of equal weight, add the above mixture in 3 times, mix for 10 minutes after each addition, and mix well. Finally, add 75% ethanol to make soft material, use 20 mesh sieve to granulate, blow dry at 60°C for 2 hours, spray lychee essence, mix, and obtain dextroibuprofen granules after 18 mesh sieve granulation, intermediate After passing the inspection, use aluminum-plastic composite bags to pack into 14600 bags according to 200mg / bag, and pack to get the fini...

Embodiment 2

[0052] Pass the dextrobuprofen, sodium carbonate, and aspartam through 80-mesh sieves respectively, and sucrose after crushing and pass through 80-mesh sieves for later use.

[0053] Weigh the raw materials of the following prescription quantities:

[0054] Dexibuprofen 100g

[0055] Sodium carbonate 300g

[0056] Sucrose 2360g

[0057] Aspartame 14g

[0058] 75% ethanol 460g

[0059] Orange essence 5g.

[0060] Fully mix aspartam, dextrobuprofen, and sodium carbonate to obtain a mixture. Divide sucrose into 3 parts of equal weight, add the above mixture in 3 times, mix for 10 minutes after each addition, and mix well. Finally, add 75% ethanol to make a soft material, use 20 mesh sieve to granulate, then blow dry at 70°C for 1.5h, spray into orange essence, and mix them all. After passing the intermediate inspection, use aluminum-plastic composite bags to divide into 13480 bags according to 200 mg / bag, and pack to obtain the finished product.

Embodiment 3

[0062] Pass the dextrobuprofen, sodium carbonate, and aspartam through 80-mesh sieves respectively, and sucrose after crushing and pass through 80-mesh sieves for later use.

[0063] Weigh the raw materials of the following prescription quantities:

[0064] Dexibuprofen 400g

[0065] Sodium carbonate 500g

[0066] Sucrose 4360g

[0067] Aspartame 60g

[0068] 75% ethanol 1300g

[0069] Green Apple Flavor 20g.

[0070] Fully mix aspartam, dextrobuprofen, and sodium carbonate to obtain a mixture. Divide sucrose into 3 parts of equal weight, add the above mixture in 3 times, mix for 10 minutes after each addition, and mix well. Finally, add 75% ethanol to make a soft material, use a 20-mesh sieve to granulate, and then dry it by air at 80°C for 1 hour. After passing the physical examination, use aluminum-plastic composite bags to pack into 25280 bags according to 200 mg / bag, and pack to get the finished product.

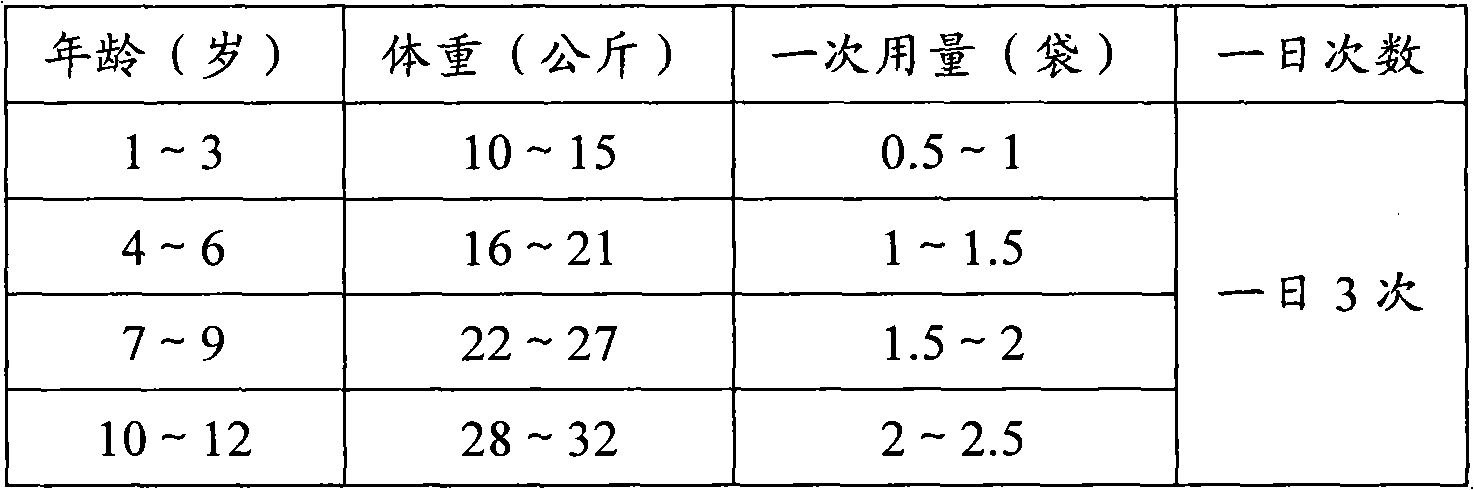

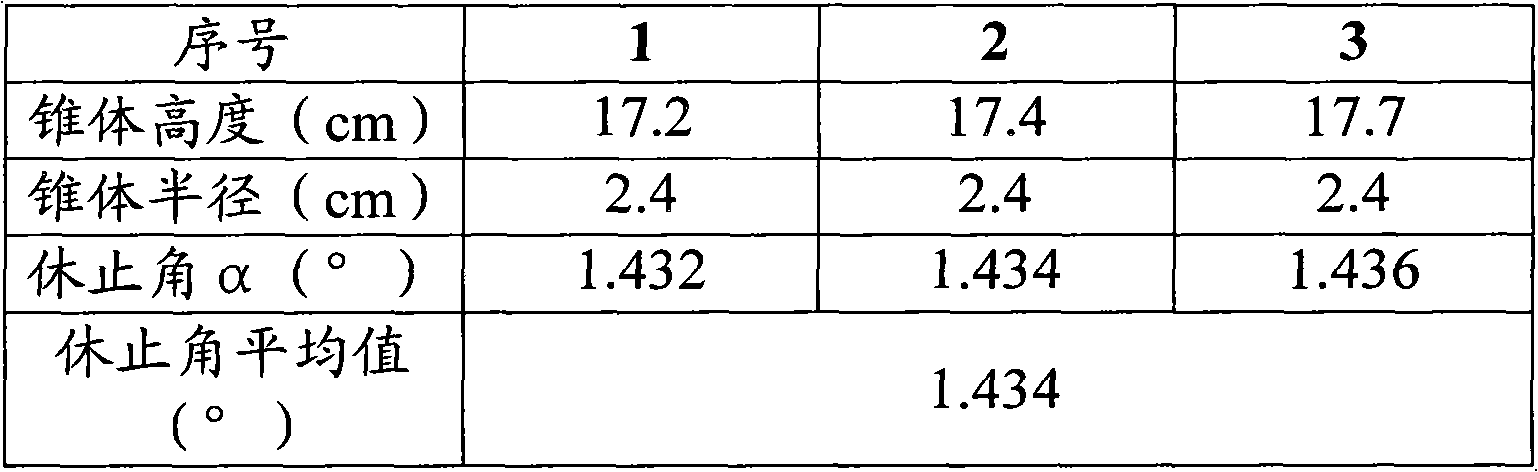

[0071] The Dexibuprofen granule that embodiment 1~3 is made...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com