Catalyst for adsorbing formaldehyde as indoor pollutant in high humility at room temperature

A high-humidity, adsorption chamber technology, applied in the fields of environmental pollution and methods, can solve problems such as the decline of formaldehyde adsorption capacity, and achieve the effects of strong formaldehyde adsorption capacity, overcoming the decline in formaldehyde adsorption capacity, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

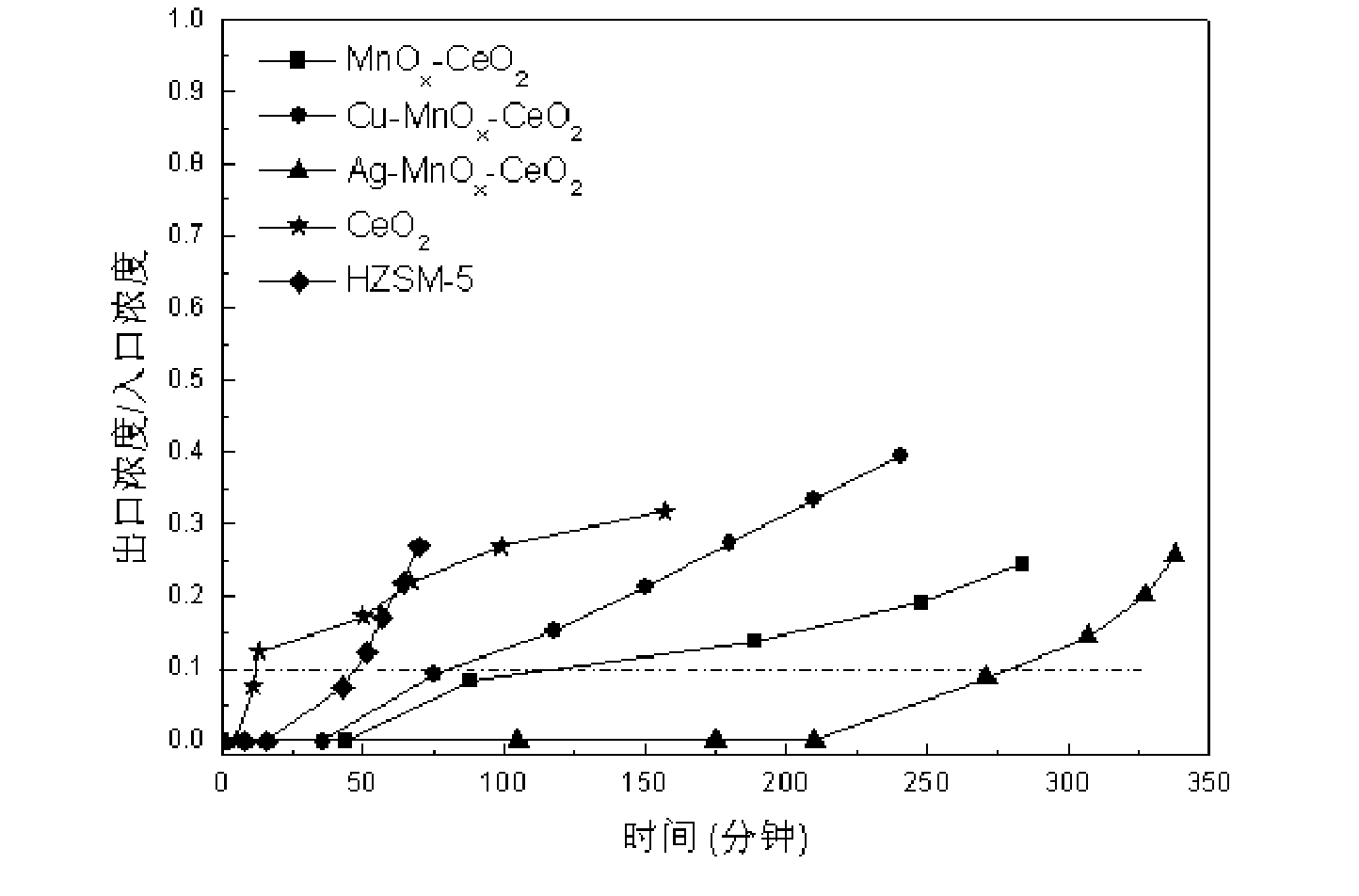

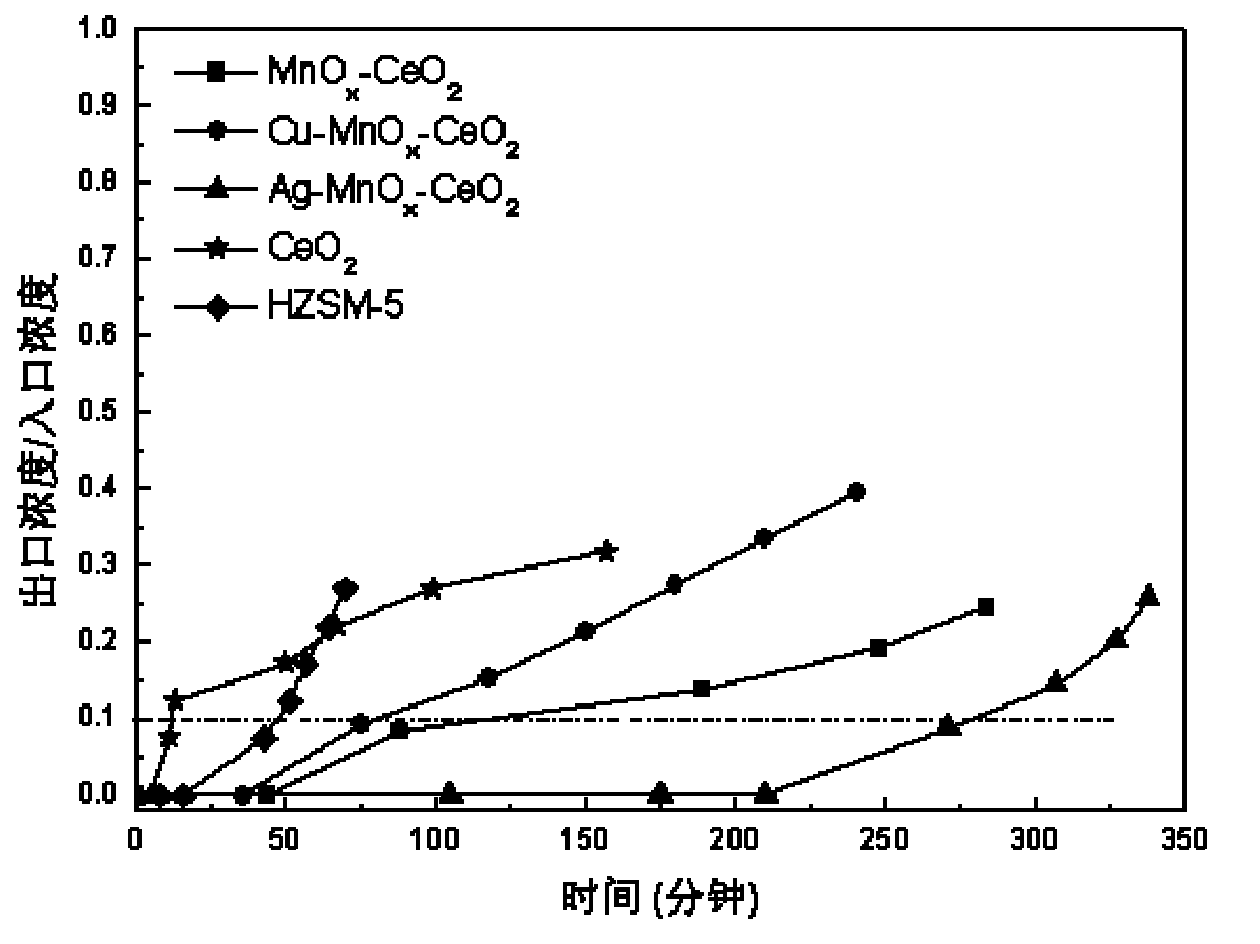

Image

Examples

example 1

[0012] Example 1: Cerium-based composite oxide Cu-MnO x -CeO 2

[0013] (1) Press Cu(NO 3 ) 2 ·3H 2 O: KMnO 4 : Mn(NO 3 ) 2 : Ce(NO 3 ) 3 ·6H 2 O=1:2:2:5 molar ratio calculation, first weigh 4.342g of Ce(NO 3 ) 3 ·6H 2 O and 0.632 g of KMnO 4 , add 100ml of deionized water to make a solution.

[0014] (2) Under magnetic stirring, add 50ml, 0.12mol L -1 MnNO 3 solution and 25ml, 0.08mol·L -1 Cu(NO 3 ) 2 solution.

[0015] (3) Use 2mol·L -1 The pH of the above solution was adjusted to 10.5 with KOH, and stirred at 50°C for 2h.

[0016] (4) After the stirring was stopped, the solution (3) was aged for 10 hours, then filtered, washed with deionized water and absolute ethanol, and then the obtained precipitate was dried in an oven at 110° C. for 12 hours.

[0017] (5) The oxide was calcined at 500°C for 6h to obtain ultrafine particle cerium-based composite oxide Cu-MnO x -CeO 2 .

example 2

[0018] Example 2: Cerium-based composite oxide Cu-TiO x -CeO 2

[0019] (1) Press Cu(NO 3 ) 2 ·3H 2 O:Ti(OC 4 h 9 ) 4 : Ce(NO 3 ) 3 ·6H 2 O=1:4:5 molar ratio calculation, first weigh 4.342g of Ce(NO 3 ) 3 ·6H 2 O and 2.723g of Ti(OC 4 h 9 ) 4 , Add 100ml of ethanol to make a solution.

[0020] (2) Under magnetic stirring, add 25ml, 0.08mol L -1 Cu(NO 3 ) 2 solution.

[0021] (3) Use 2mol·L -1 The pH of the above solution was adjusted to 10.5 with KOH, and stirred at 50°C for 2h.

[0022] (4) After the stirring was stopped, the solution (3) was aged for 10 hours, then filtered, washed with deionized water and absolute ethanol, and then the obtained precipitate was dried in an oven at 110° C. for 12 hours.

[0023] (5) The oxide was calcined at 500°C for 6h to obtain ultrafine particle cerium-based composite oxide Cu-TiO x -CeO 2 .

example 3

[0024] Example 3: Cerium-based composite oxide Cu-ZnO x -CeO 2

[0025] (1) Press Cu(NO 3 ) 2 ·3H 2 O:Zn(NO 3 ) 2 ·6H 2 O: Ce(NO 3 ) 3 ·6H 2 O=1:4:5 molar ratio calculation, first weigh 4.342g of Ce(NO 3 ) 3 ·6H 2 O and 2.380g of Zn(NO 3 ) 2 ·6H 2 O, add 100ml of deionized water to make a solution.

[0026] (2) Under magnetic stirring, add 25ml, 0.08mol L -1 Cu(NO 3 ) 2 solution.

[0027] (3) Use 2mol·L -1 The pH of the above solution was adjusted to 10.5 with KOH, and stirred at 50°C for 2h.

[0028] (4) After the stirring was stopped, the solution (3) was aged for 10 hours, then filtered, washed with deionized water and absolute ethanol, and then the obtained precipitate was dried in an oven at 110° C. for 12 hours.

[0029] (5) Calcinate the oxide at 500°C for 6h to obtain ultrafine particles of cerium-based composite oxide Cu-ZnO x -CeO 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com