Method for quickly starting oxygen-poor ammonia oxidizing biofilter

A biofilter and quick-start technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as large energy consumption and large sludge production, and achieve economical operation Low cost, low sludge production, and chemical reagent saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] At normal temperature, hydraulic retention (increase the hydraulic load once on the 64th day of the period); pH value is controlled to be weakly alkaline; dissolved oxygen (DO) is controlled by sealing all containers.

[0025] Since hydroxylamine and hydrazine are important intermediate products in the process of anoxic ammonium oxidation and can induce the biological reaction of anoxic ammonium oxidation, hydroxylamine or hydrazine was added to the test raw water at the stage of starting the anoxic ammonium oxidation test to achieve inoculation. Rapid transformation of sludge into anoxic ammonium oxidation biofilm.

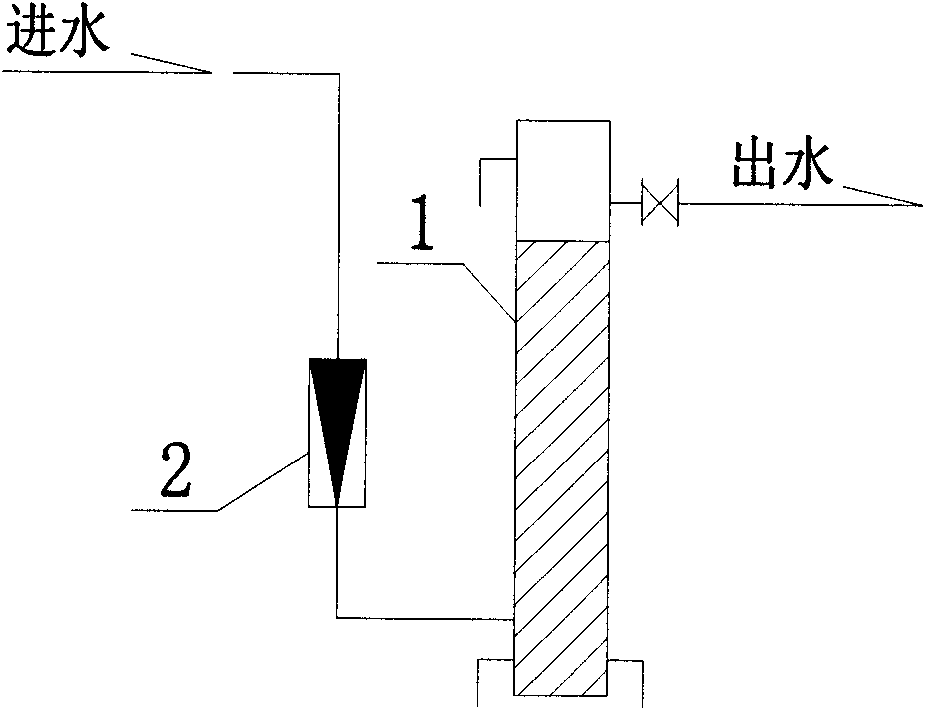

[0026] The reactor is used as a biological filter, and the filter material is ceramsite.

[0027] Inoculation of denitrification biofilm, operation and cultivation of anoxic ammonium oxidizing bacteria can achieve a more ideal denitrification effect, and realize the rapid start-up of anoxic ammonium oxidation biofilter.

[0028] The successful start-up ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com