Phenylo boric acid-silane-ethynyl polymer and preparation method thereof

A technology of phenylboronic acid and ethynyl, which is applied in the field of phenylboronic acid-silane-ethynyl polymer and its preparation, can solve problems such as thermal rearrangement degradation, and achieve the effects of convenient operation, abundant sources, and simple synthesis process

Inactive Publication Date: 2010-09-15

EAST CHINA UNIV OF SCI & TECH

View PDF4 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach 1

Embodiment approach 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

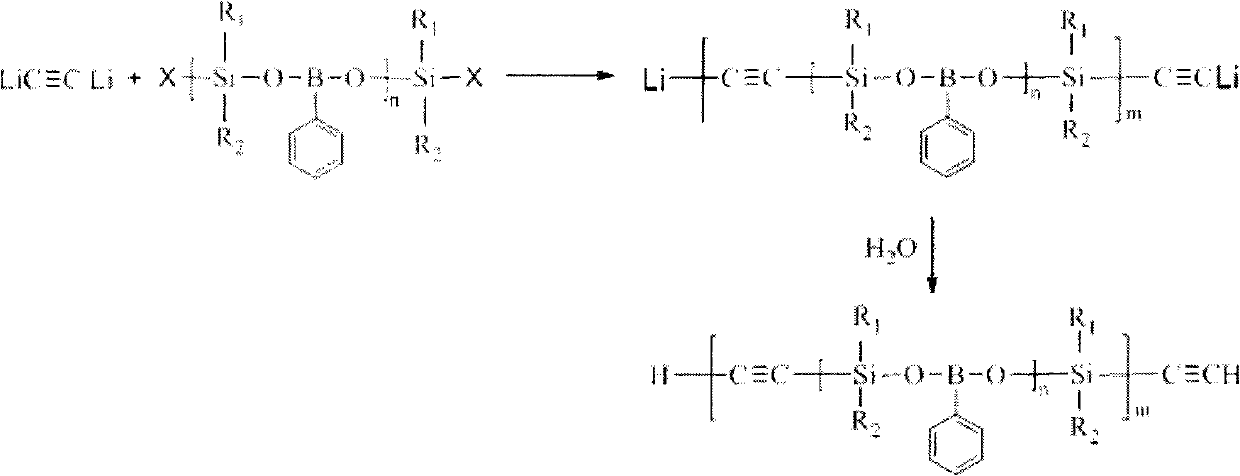

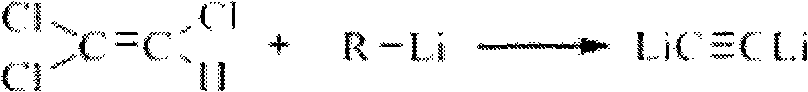

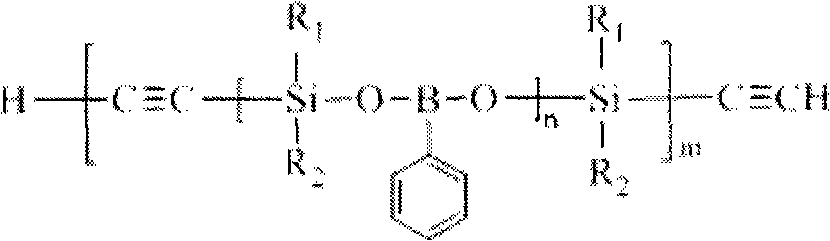

The invention discloses phenylo boric acid-silane-ethynyl polymer and a preparation method thereof. The polymer is prepared by taking dihalo-silane, phenylo boric acid, trichloroethylene and organic lithium as raw materials in three-step reaction under the protection of inert gas. In the first step, the phenylo boric acid and the dihalo-silane react to form a polymer with a silane-phenylo boric acid-silane repetitive structure and halogen-sealed end. In the second step, the trichloroethylene and the organic lithium react to form an ethynyl dilithium. Finally, the ethynyl dilithium and the polymer formed in the first step generate coupling reaction to obtain the final product after hydrolyzation. The used raw materials are easy to obtain, the process flow is simple, and the operation process is feasible. The prepared polymer generates crosslinking reaction to form thermosets with good high temperature resistance and thermal oxidation resistance property under the thermal or chemical initiation, and is further heated to form a ceramic structure. The prepared polymer can be used as matrix resin, high temperature-resistance coating and ceramic precursor of the advanced composite material.

Description

technical field The invention relates to a high-temperature-resistant and thermal-oxidation-resistant polymer, in particular to an organic-inorganic hybrid polymer containing boron, silicon and acetylene groups in the main chain, and the main chain is composed of Si-O-B and C≡C. The ethynyl group undergoes a curing crosslinking reaction under the action of light, heat or an initiator to form a three-dimensional network structure, and further forms a ceramic structure under the action of high temperature. Background technique Silicone resin is a polymer with Si-O-Si bond as the main molecular chain and organic groups connected to silicon atoms. Its structure contains both organic groups and inorganic structures. This special composition and molecular structure make it a combination of organic properties and inorganic functions, with unique physical and chemical properties, such as excellent heat resistance, cold resistance, electrical insulation and weather resistance, and ar...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08G77/50

Inventor 周权倪礼忠程睿

Owner EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com