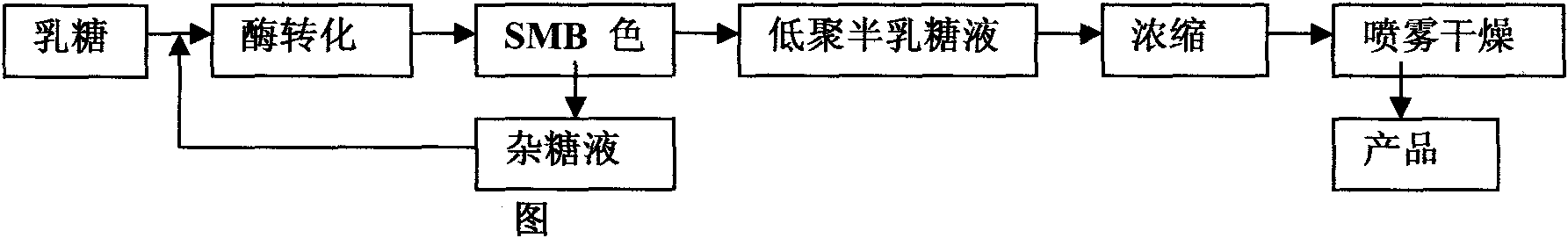

Method for producing high-purity oligomate

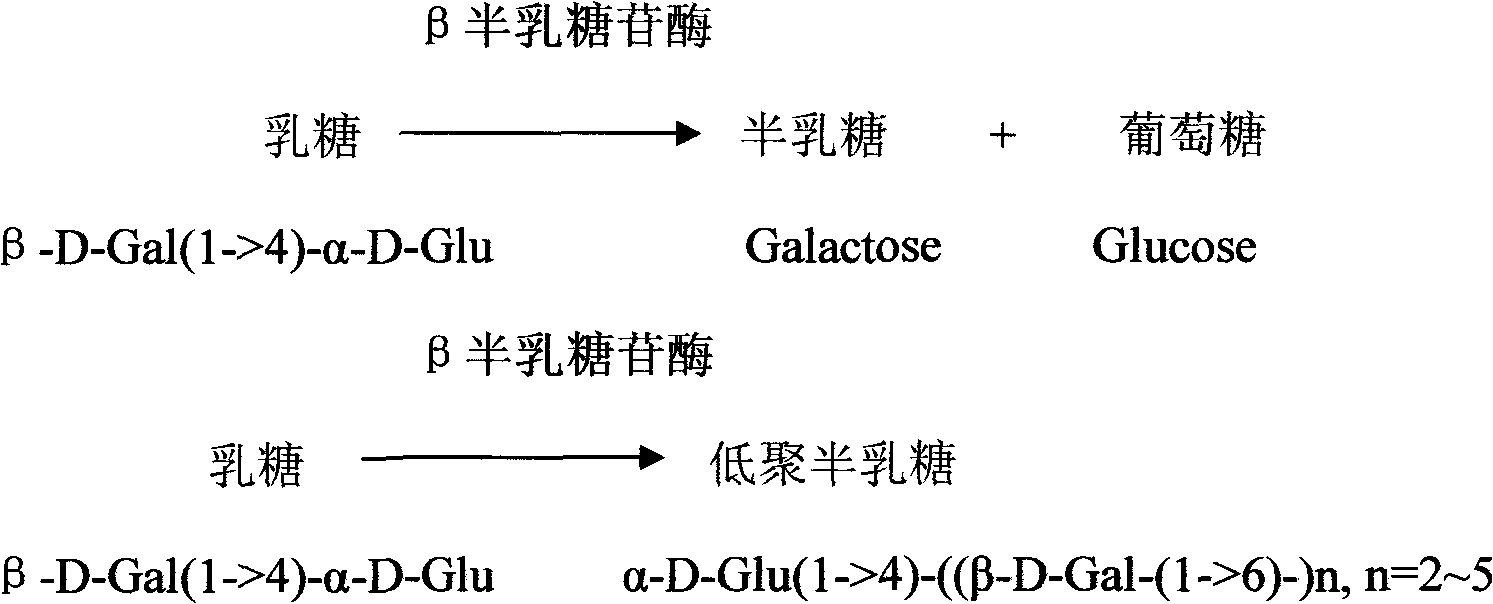

A high-purity galacto-oligosaccharide technology, applied in oligosaccharides, chemical instruments and methods, and sugar derivatives, can solve the problems of low separation efficiency, large mobile phase consumption, and high production costs in fixed-bed chromatography. Achieve the effects of low production cost, increased yield and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

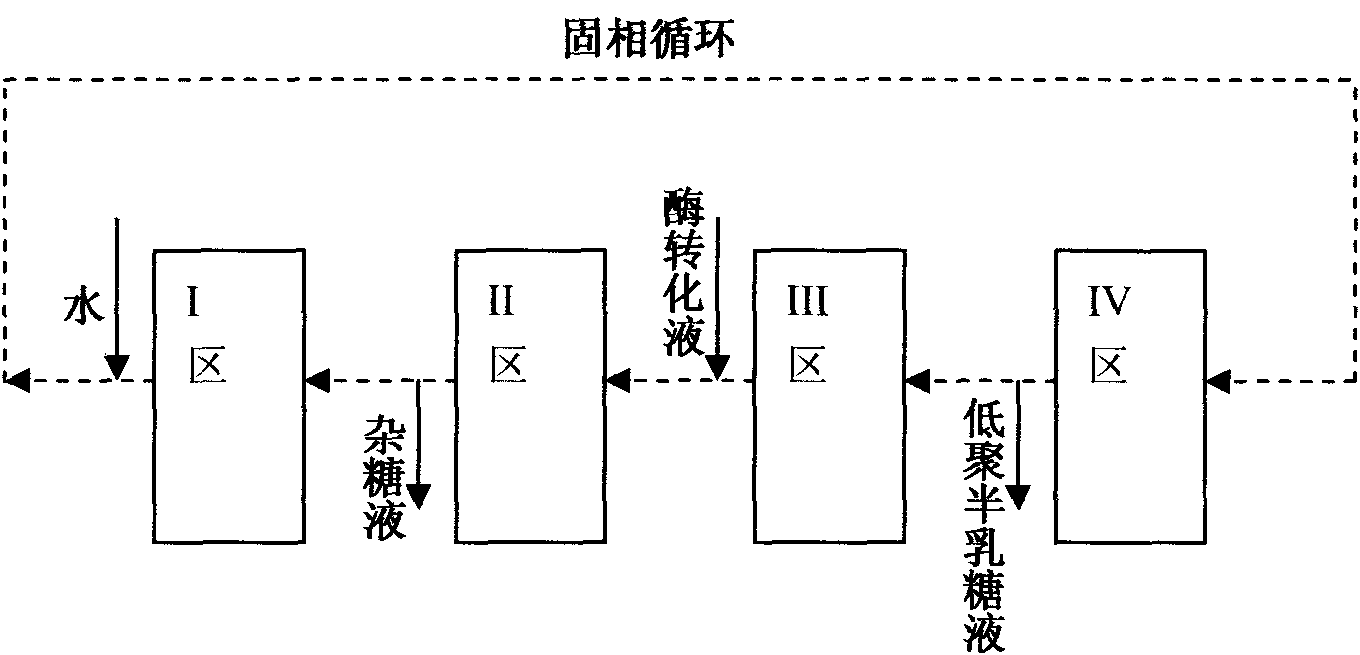

Method used

Image

Examples

Embodiment 1

[0044] The feeding material is lactose solution with a concentration of 300g / L passing through the immobilized enzyme reaction column equipped with β-galactosidase, the reaction temperature is 50°C, and the reaction pH is 5.0. The content of galacto-oligosaccharides in the outflowing enzyme conversion liquid is 45%, lactose 18%, galactose 12%, and glucose 25%. The enzyme conversion solution was passed through simulated moving bed chromatography, and the operating conditions of the simulated moving bed chromatography system were as follows: separation temperature 60°C, feed flow rate 1 liter / hour, eluting water flow rate 1.7 liters / hour, system operating pressure 1.0MP, feed Reach stable after 20 hours, the discharge situation that obtains is as follows:

[0045] 1) Galacto-oligosaccharide part: the dry matter concentration is about 13% (~1.1 times the volume of the feed); the purity of galacto-oligosaccharide is 87.2%, lactose is 11.0%, galactose is 0.5%, and glucose is 1.0%. ...

Embodiment 2

[0048] The feed is that lactose solution with a concentration of 400g / L passes through the immobilized enzyme reaction column equipped with β-galactosidase, the reaction temperature is 55°C, and the reaction pH is 5.5. The content of galacto-oligosaccharides in the outflowing enzyme conversion solution was 56%, lactose 18%, galactose 4%, and glucose 22%. The enzyme conversion solution was passed through simulated moving bed chromatography, and the operating conditions of the simulated moving bed chromatography system were as follows: separation temperature 65°C, feed flow rate 1 liter / hour, eluting water flow rate 2.9 liters / hour, system operating pressure 1.1MP, feed Reach stable after 20 hours, the discharge situation that obtains is as follows:

[0049] 1) Galacto-oligosaccharide part: the dry matter concentration is about 14% (~2.8 times the volume of the feed); the purity of galacto-oligosaccharide is 92%, lactose is 6.1%, galactose is 0.3%, and glucose is 1.3%.

[0050]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com