Double-working substance heat source sintering cogeneration-type boiler system

A waste heat boiler and duplex technology, applied in furnaces, waste heat treatment, energy industry, etc., can solve the problems of single, low waste heat recovery rate, etc., and achieve the effect of reducing height, compact boiler structure and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the drawings and embodiments.

[0017] This embodiment uses 320m 2 The sensible heat of the sintering machine and the recovery of the sensible heat of the sintering machine’s mid- and low-temperature flue gas are described as examples. The cooler matched with the sintering machine 39 is a vertical cooler 38, and the power generation type waste heat boiler 23 is a vertical arrangement with negative pressure run.

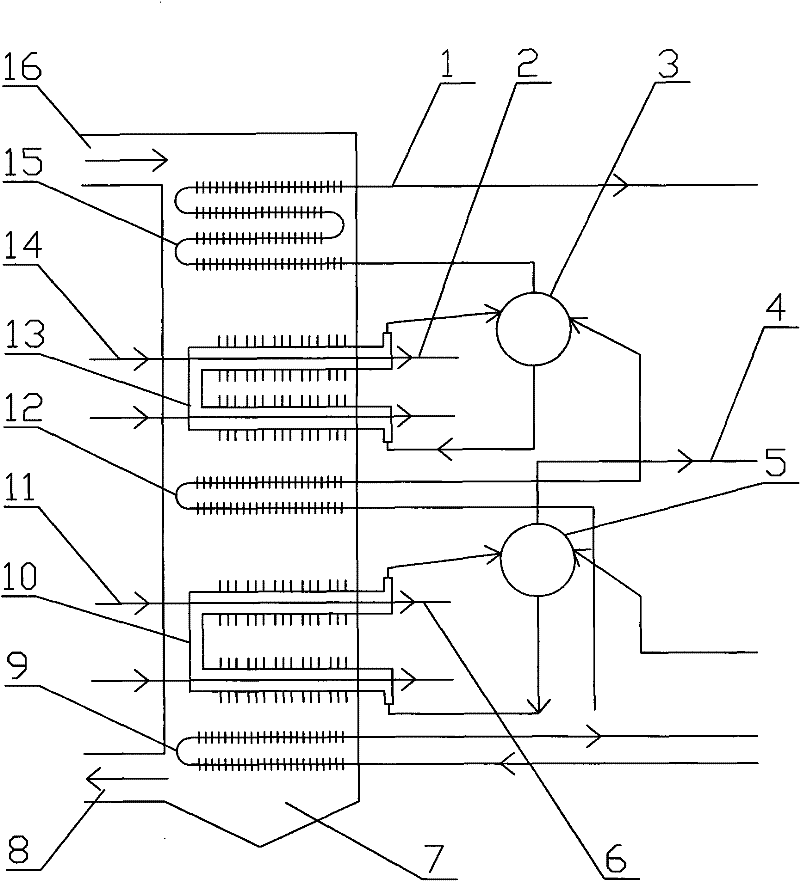

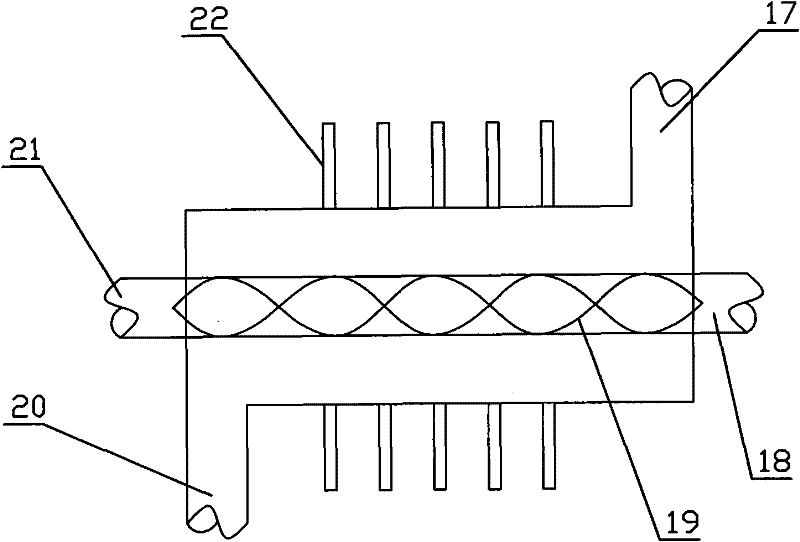

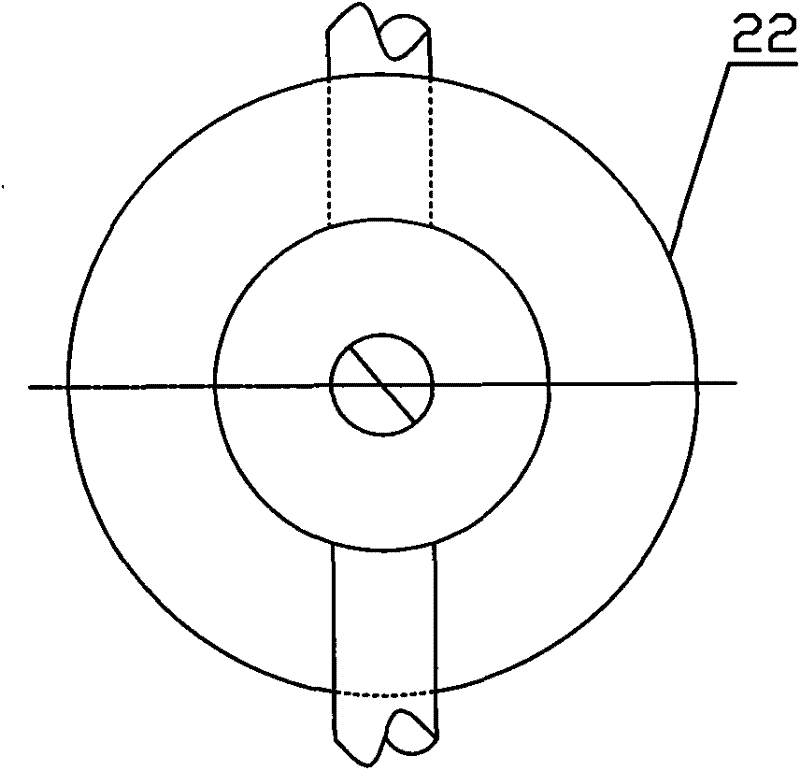

[0018] See Figure 4 , The present invention is composed of a vertical cooler 38, a sintering machine 39, a power generation waste heat boiler 23, a condensing steam supplementary steam turbine 28, and a generator 29. The power generation waste heat boiler 23 is arranged in sequence from top to bottom in the furnace body There are a medium-pressure superheater 15, a sleeve-type medium-pressure evaporator 13, a medium-pressure economizer 12, a sleeve-type low-pressure evaporator 10, and a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com