Reprocessed cheese capable of being preserved at normal temperature and preparation method thereof

A technology of processed cheese and storage at room temperature, applied in cheese substitutes, dairy products, applications, etc., can solve the problems of inconvenient consumption and storage, corruption and deterioration, and achieve excellent water solubility, extended shelf life, and high oxygen resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

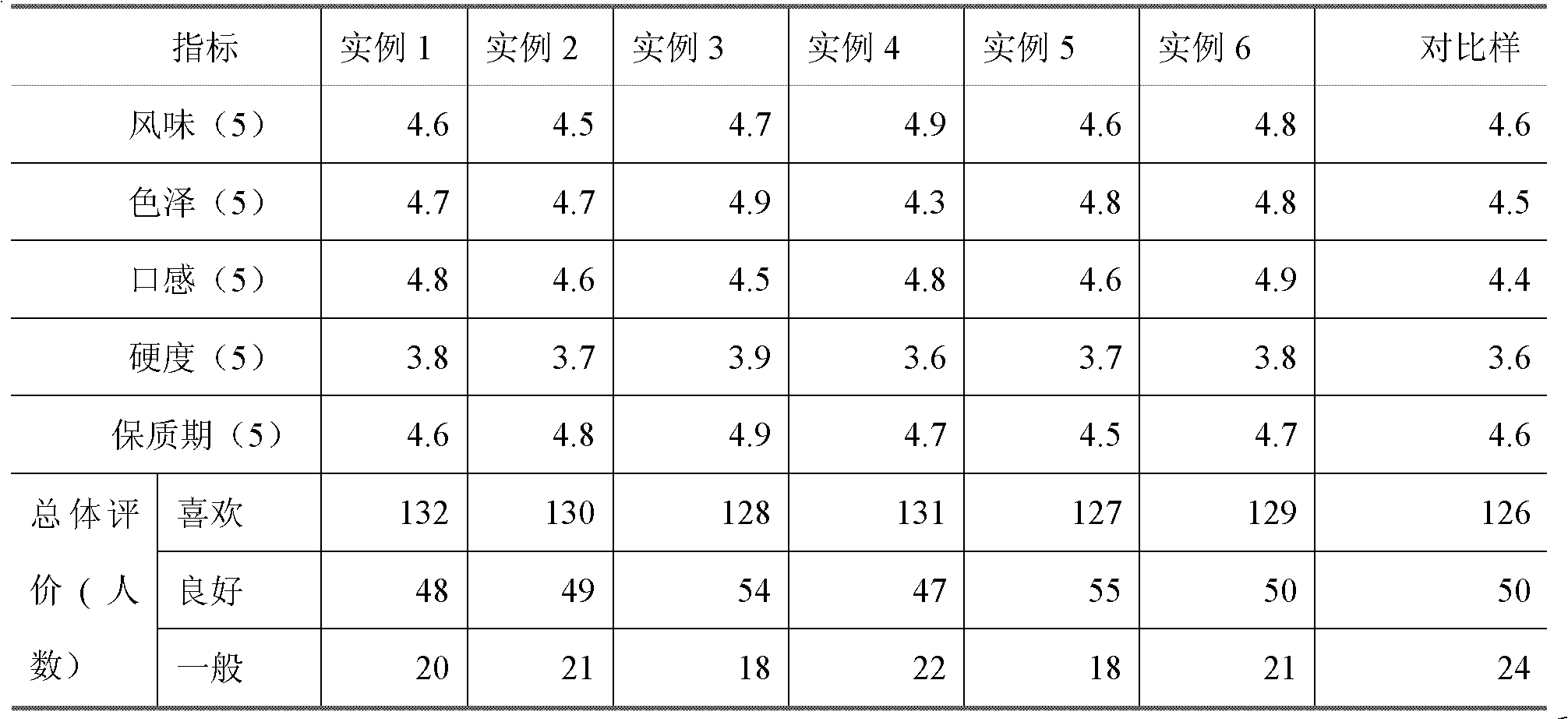

Examples

Embodiment 1

[0029] formula

[0030] Ingredient Name Addition % Addition (g / kg)

[0031] Natural cheese (ripened for 1 month) 12.5 125

[0032] Natural cheese (aged for 6 months) 15.0 150

[0033] Whey powder 10.0 100

[0034] Skim milk powder 8.0 80

[0035] Butter 10 100

[0036] Emulsifying salt 3.0 30

[0037] Nisin 0.3 3.0

[0038] Dietary fiber 3.0 30

[0039] Purified water 37.9 379

[0040] Smoke liquid 0.3 3.0

[0041] Raw material standard:

[0042] Natural cheese: protein ≥ 25%, fat ≥ 35%, moisture ≤ 40%

[0043] Whey powder: protein ≥ 10%, fat ≥ 2%, water ≤ 5%, ash ≤ 13%

[0044] Skimmed milk powder: protein ≥ 28%, fat ≥ 2%, moisture ≤ 5%

[0045] Butter: fat ≥ 78%, moisture ≤ 10%, non-fat solid content ≤ 3%.

[0046] Other components meet the national food standards.

[0047] A method for preparing processed cheese that can be stored at room temperature, the preparation process is as follows:

[0048]①Cut the selected natural cheese into 1-2cm cubes to increase ...

Embodiment 2

[0058] formula

[0059] Ingredient Name Addition % Addition (g / kg)

[0060] Natural cheese (ripened for 1 month) 12.5 125

[0061] Natural cheese (aged for 6 months) 15.0 150

[0062] Whey powder 10.0 100

[0063] Skim milk powder 8.0 80

[0064] Butter 10.0 100

[0065] Potassium sorbate 0.1 1.0

[0066] Emulsifying salt 3.0 30

[0067] Nisin 0.3 3.0

[0068] Purified water 37.8 378

[0069] Dietary fiber 3.0 30

[0070] Smoke liquid 0.3 3.0

[0071] Raw material standard is the same as embodiment 1.

[0072] The steps of its preparation method are the same as in Example 1.

Embodiment 3

[0074] formula

[0075] Ingredient Name Addition % Addition (g / kg)

[0076] Natural cheese (ripened for 1 month) 12.5 125

[0077] Natural cheese (aged for 6 months) 15.0 150

[0078] Whey powder 10.0 100

[0079] Skim milk powder 8.0 80

[0080] Butter 10.0 100

[0081] Emulsifying salt 3.0 30

[0082] Nisin 0.3 3.0

[0083] Sodium Benzoate 0.1 1.0

[0084] Applesauce 3.0 30

[0085] Water 37.8 378

[0086] Smoke liquid 0.3 3.0

[0087] Raw material standard is the same as embodiment 1.

[0088] The steps of its preparation method are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com