Desulfuration process and device thereof

A desulfurization process and desulfurization device technology, which are applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of high system operation cost, complex device structure, large investment cost, etc., to reduce secondary pollution and simplify. Structure, the effect of saving coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

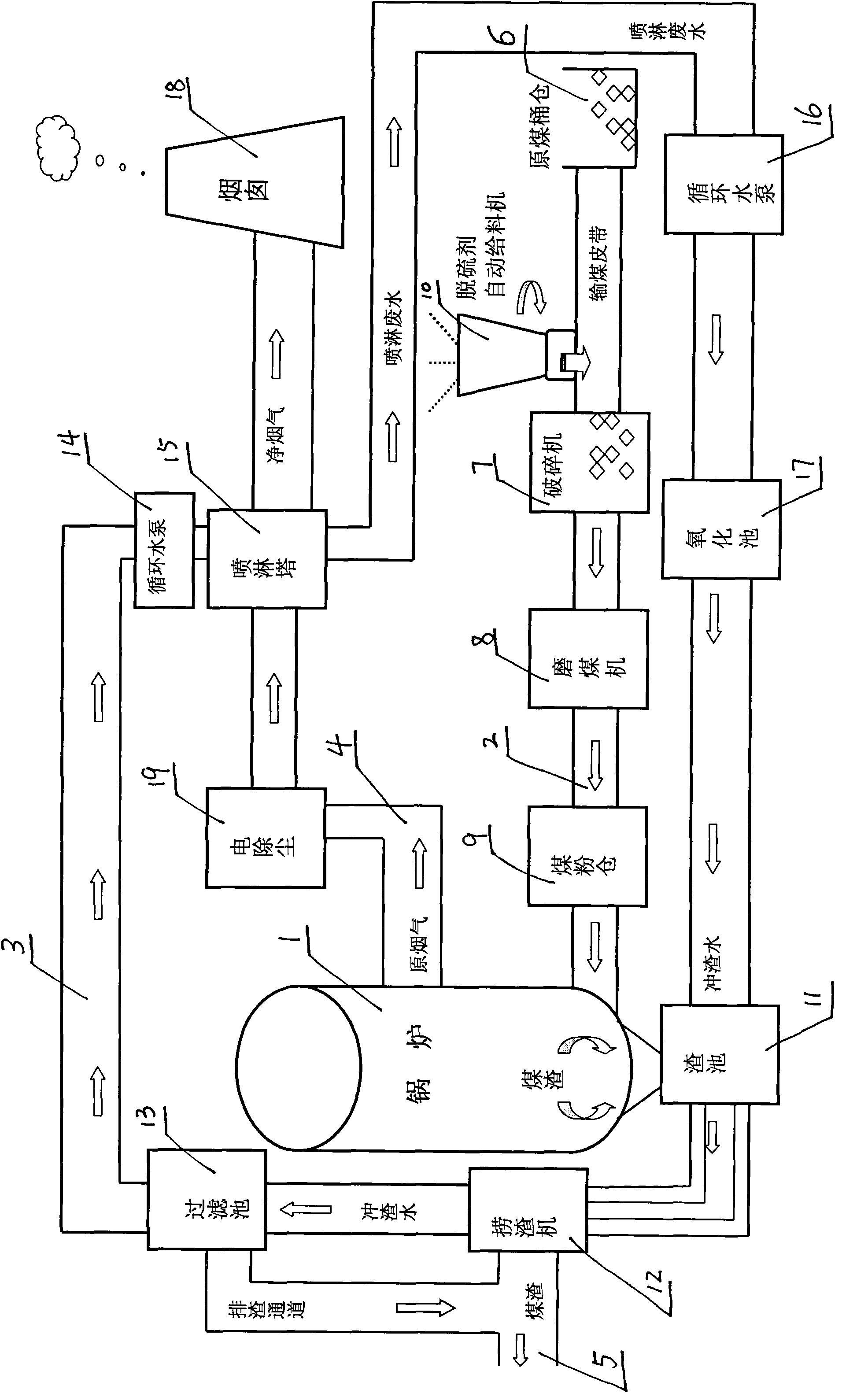

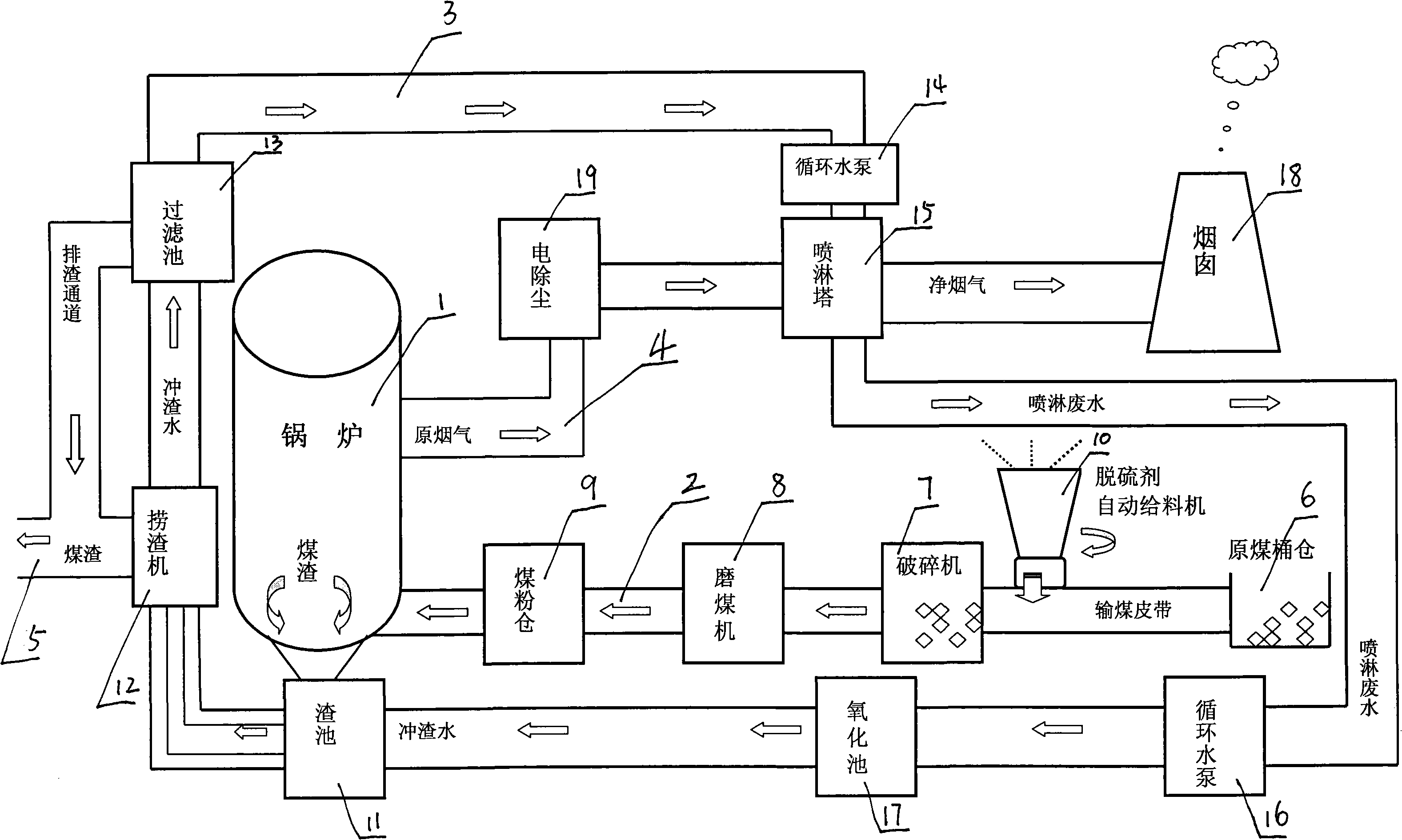

[0021] Embodiment 1, a desulfurization device includes a boiler 1 , a coal inlet passage 2 connected to the boiler 1 , a circulating water pipe 3 and a flue 4 , and the circulating water pipe 3 passes through the flue 4 and communicates with a slag discharge passage 5 .

[0022] The coal inlet passage 2 communicates with the side wall of the boiler 1 , the circulating water pipe 3 communicates with the bottom of the boiler 1 , and the flue 4 communicates with the upper part of the boiler 1 .

[0023] Coal inlet channel 2 is provided with raw coal barrel bin 6, crusher 7, and coal mill 8 in sequence, and coal mill 8 is connected with boiler 1 through coal powder bin 9; between raw coal barrel bin 6 and crusher 7, there is a desulfurizer Automatic feeder 10; slag pool 11, slag extractor 12, filter pool 13, circulating water pump 14, spray tower 15, circulating water pump 16 and oxidation pool 17 are arranged in turn on the circulating water pipeline 3, and the slag pool 11 is set...

Embodiment 2

[0025] In Example 2, the desulfurization device and desulfurization process used are the same as in Example 1, and the raw material composition and addition amount of the desulfurizer used are shown in Table 1.

Embodiment 3

[0026] In Example 3, the desulfurization device and desulfurization process used are the same as in Example 1, and the raw material composition and addition amount of the desulfurizer used are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com