Car body adaptable to high-temperature and high-humidity areas and coating method thereof

A coating method and vehicle body technology, which are applied to the device for coating liquid on the surface, the coating, the pretreatment surface, etc., can solve the problems of coating peeling, inability to adapt to the high temperature and high humidity environment, etc., and improve the weather resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

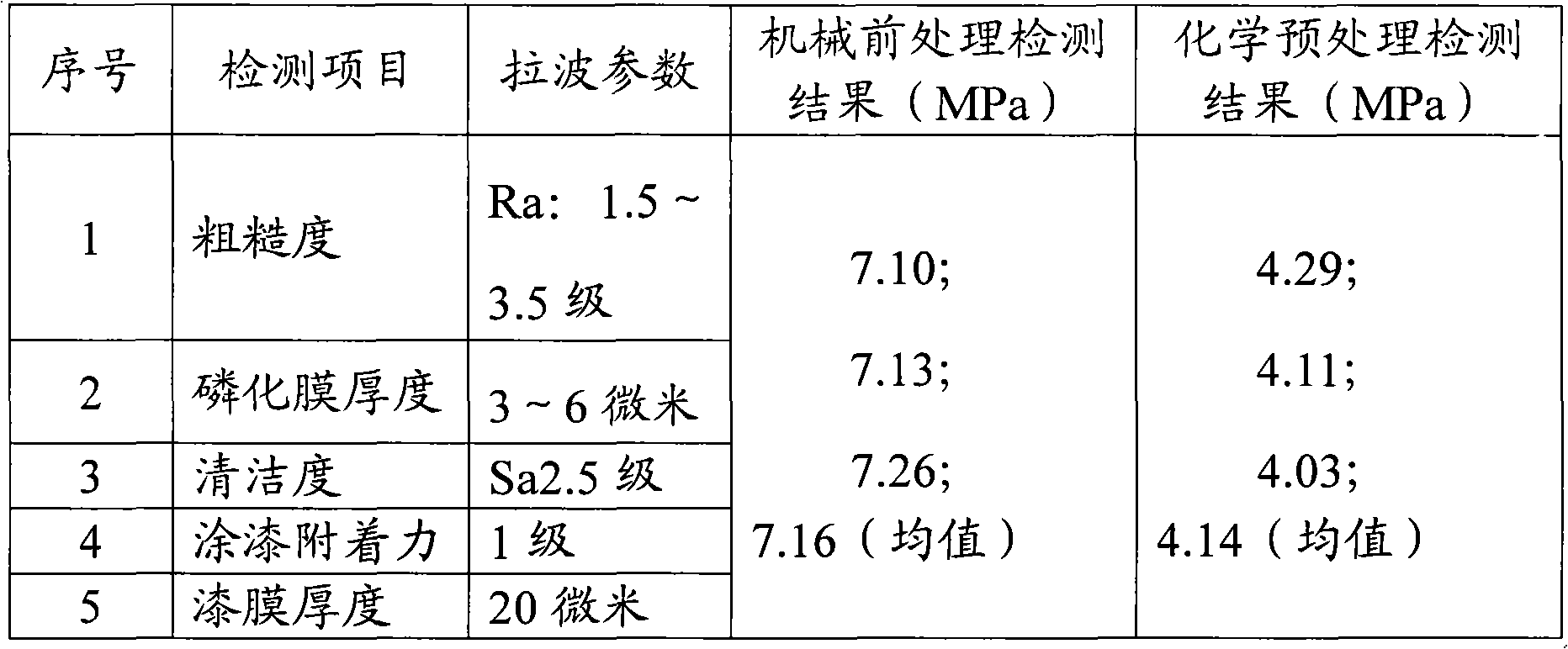

[0026] Embodiment 1: Embodiment of the coating method of the side wall of the car body

[0027] In order to meet the operating requirements of vehicles in high-temperature and high-humidity environments, the coating system for the side wall of the car body includes primer, putty, anti-corrosion paint, primer, top coat and varnish. The specific coating method includes the coating of the side wall of the car body The surface is subjected to mechanical pretreatment by spraying river sand, primer coating, putty scraping, anti-corrosion paint spraying, mid-coat spraying, top coat spraying and overcoat varnish etc. The thickness indexes of varnish and varnish are 60μm, 3mm, 40μm, 40μm, 60μm and 40μm respectively, where:

[0028] The primer is epoxy antirust paint: the molecular skeleton of epoxy phenolic resin is mainly composed of carbon bonds and ether bonds, and its chemical properties are stable. After curing, it forms a dense cross-linked network structure. Low, so it has exce...

Embodiment 2

[0034] Embodiment 2: Embodiment of the coating method of the roof

[0035] The roof of the car is directly exposed to harsh weather conditions such as strong ultraviolet light and rain, so a coating system with excellent comprehensive performance is required. For this reason, this preferred embodiment uses fluorocarbon paint as the middle coat, top coat and varnish. Ultraviolet performance, weather resistance durability, acid and alkali resistance, high temperature medium resistance and excellent wear resistance; coupled with the low surface tension of the paint film, rainwater is not easy to stay on the paint film, and it is not easy to stick dust and easy to clean. The coating system of the embodiment of the vehicle roof coating method includes: epoxy antirust paint, fluorocarbon intermediate coating, fluorocarbon topcoat and fluorocarbon varnish.

[0036] The specific coating method of the roof includes mechanical pretreatment of the roof surface by spraying river sand, co...

Embodiment 3

[0037] Embodiment 3: Embodiment of the coating method of the underframe and the bogie

[0038] In high-temperature and high-humidity areas, the underframe and bogie of the vehicle are in a high-temperature and high-humidity state for a long time, and the operating environment is harsh. Referring to the ship coating process, epoxy anti-rust primer, epoxy high-build paint, high-solid polypropylene micro The heavy-duty anti-corrosion coating process of the elastic topcoat, the paint film is tough, water-resistant, wear-resistant, and collision-resistant, suitable for high-speed train underbody coating.

[0039] The specific coating methods of the chassis and bogies include mechanical pretreatment of the surface of the chassis and bogies by spraying river sand, coating epoxy anti-rust primer, spraying epoxy thick build paint and spraying high solid content Steps such as polypropylene microelastic topcoat, the thickness indicators of epoxy antirust primer, epoxy high build paint an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com