Dilute nitric acid preparing method meeting requirements of energy saving and emission reduction as well as low cost and device

A technology of dilute nitric acid and nitric acid, applied in the direction of nitric acid, separation methods, chemical instruments and methods, etc., can solve problems such as environmental pollution, achieve the effects of convenient operation, simple structure, and reduced cost of acid preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (To use 98% concentrated nitric acid and 58% dilute nitric acid to prepare 100m 3 , the concentration is 68% dilute nitric acid as an example, specifically explaining the method for preparing dilute nitric acid in an environment-friendly manner. )

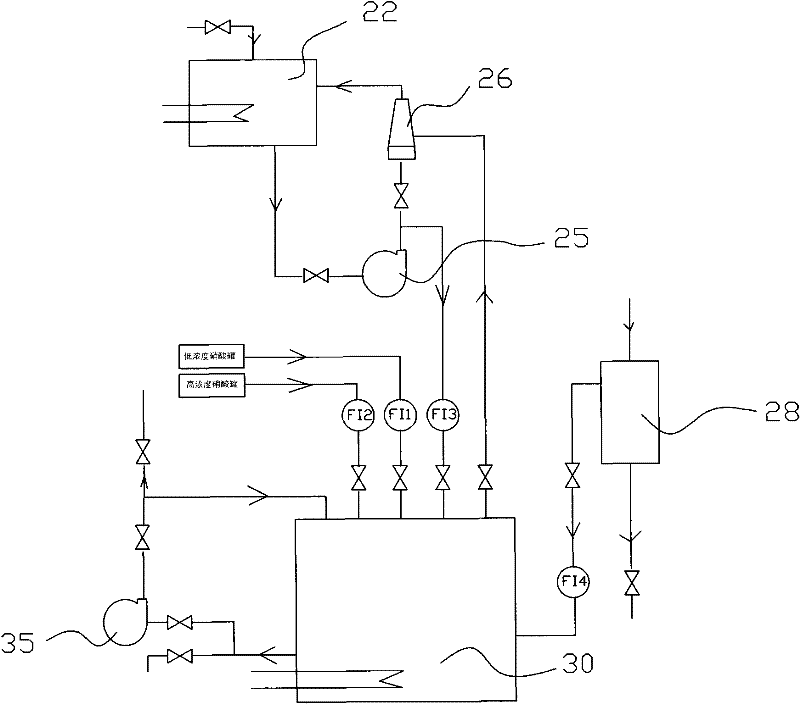

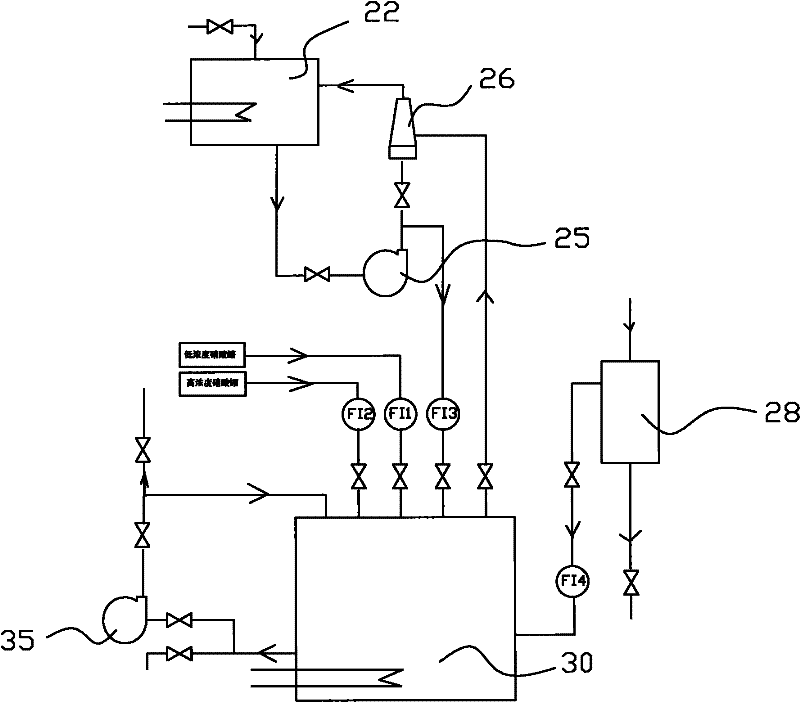

[0019] Such as figure 1 as shown,

[0020] 1. According to the volume ratio of concentrated nitric acid and dilute nitric acid 1:2.8711, measure through the flow meter FI1, 74.1675m of 58% dilute acid 3 Inject the stainless steel acid tank 30, open the dilute acid pump 35, circulate the 58% dilute nitric acid in the stainless steel acid tank 30, and release the undissolved part nitrogen oxide gas from the dilute nitric acid;

[0021] 2. Lead the process soft water into the liquid distribution pipe on the tower tail water tank 22 and maintain the liquid level of the tower tail water tank 22 at 30%~50%;

[0022] 3. According to the volume ratio of concentrated nitric acid and dilute nitric acid 1: 2.8711, measure through f...

Embodiment 2

[0027] (to use 98% concentrated nitric acid and the dilute nitric acid preparation 100m of the 1-3% that the tower tail tank 22 of embodiment 1 obtains 3 , the concentration is 68% dilute nitric acid as an example, specifically explaining the method for preparing dilute nitric acid in an environment-friendly manner. )

[0028] Such as figure 1 Shown:

[0029] 1. Turn on the special injection acid pump 25, according to the volume ratio of concentrated nitric acid and dilute nitric acid 1.7526:1, through the flow meter FI3, dilute nitric acid from the tower tail tank 22 with a concentration of 1% to 3% is injected into the stainless steel acid tank 30. When the flow meter FI3 measurement shows 36.3293m 3 , keep the indication on the vacuum gauge P1 on the outlet pipe of the acid pump 26 as 80-90Kpa, so as to remove the uncombined nitrogen oxides in the stainless steel dilute acid tank 30. Turn on the dilute acid pump 35 to circulate the 1% to 3% dilute nitric acid in the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com