Preparation method of lycopene

A technology for lycopene and tomato, applied in chemical instruments and methods, extraction purification/separation, bulk chemical production, etc., can solve the problems of poor product quality, odorous solvents, low purity, etc., and achieve the effect of improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1, the preparation method of lycopene

[0017] Weigh 30kg of mature tomato and beat it, centrifuge the slurry at 3500r / min for 30min, dry the sediment after centrifugation in a vacuum drying oven at 38°C for 12 hours, grind it with a colloid mill, put the ground tomato sample into the extraction kettle, and close the lid of the kettle. Control the temperature of the reactor to 40°C and the pressure to 30Mpa, and introduce supercritical carbon dioxide fluid, and circulate the extraction for 1 hour; then change the temperature and pressure of the reactor so that the temperature of the reactor is 70°C, and the pressure is 35Mpa, and continue the extraction for 1 hour; the amount of carbon dioxide : 10L / 1kg (volume of carbon dioxide / weight of tomato); after the extraction is completed, reduce the pressure to 4.5Mpa, separate the extracted substance, and spray dry to obtain 4.2g orange-red powder.

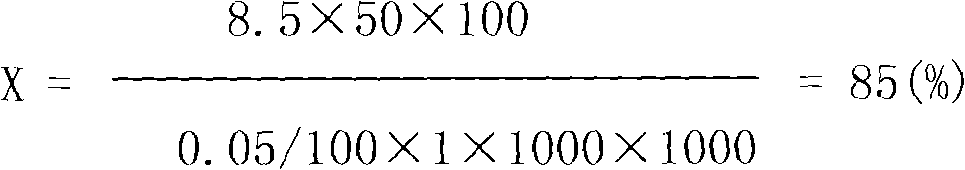

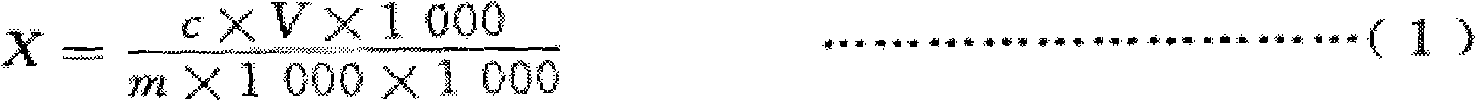

[0018] Weigh 0.05g of the orange-red powder and place it in a 100...

Embodiment 2

[0032] Embodiment 2, the preparation method of lycopene

[0033] Weigh 30kg of mature tomato and beat it, centrifuge the slurry at 3500r / min for 30min, dry the centrifuged sediment in a vacuum oven at 38°C for 12 hours, grind it with a colloid mill, put the ground tomato sample into the extraction kettle, and close the lid of the kettle , control the temperature of the reactor to be 45°C and the pressure of 15Mpa, feed supercritical carbon dioxide fluid, and circulate the extraction for 1 hour; then change the temperature and pressure of the reactor so that the temperature of the reactor is 50°C, and the pressure is 20Mpa, and continue to extract for 1 hour; carbon dioxide Dosage: 10L / 1kg (volume of carbon dioxide / weight of tomato); after the extraction is completed, reduce the pressure to 4.5Mpa, separate the extracted substance, and spray dry to obtain 4g of orange-red powder.

[0034] Weigh 0.05g of the orange-red powder and place it in a 100mL brown volumetric flask, add p...

Embodiment 3

[0048] Embodiment 3, the preparation method of lycopene

[0049] Weigh 30kg of ripe tomato and beat it, centrifuge the slurry at 3500r / min for 30min, dry the centrifuged precipitate in a vacuum oven at 38°C for 12 hours, grind it with a colloid mill, put the ground tomato sample into the extraction kettle, add ethanol, ethanol The amount is 1.5kg, close the lid of the kettle, control the temperature of the reactor to be 60°C, the pressure of 25Mpa, feed supercritical carbon dioxide fluid, and circulate the extraction for 1 hour; then change the temperature and pressure of the reactor so that the temperature of the reactor is 65°C, and the pressure 15Mpa, continue to extract for 1 hour; carbon dioxide dosage: 18L / 1kg (carbon dioxide volume / tomato weight); after the extraction is completed, reduce the pressure to 5Mpa, separate the extracted substance, and spray dry to obtain 3.8g orange-red powder.

[0050] Weigh 0.05g of the orange-red powder and place it in a 100mL brown volu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com