Method and equipment for preparing fatty alcohol (ether) phosphate

A technology for manufacturing equipment and manufacturing methods, which is applied in chemical instruments and methods, phosphorus organic compounds, compounds of Group 5/15 elements of the periodic table, etc., and can solve the problem of deepening product color, low product purity, and inability to disperse well, etc. problem, to achieve the effect of fast reaction speed and high reaction conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

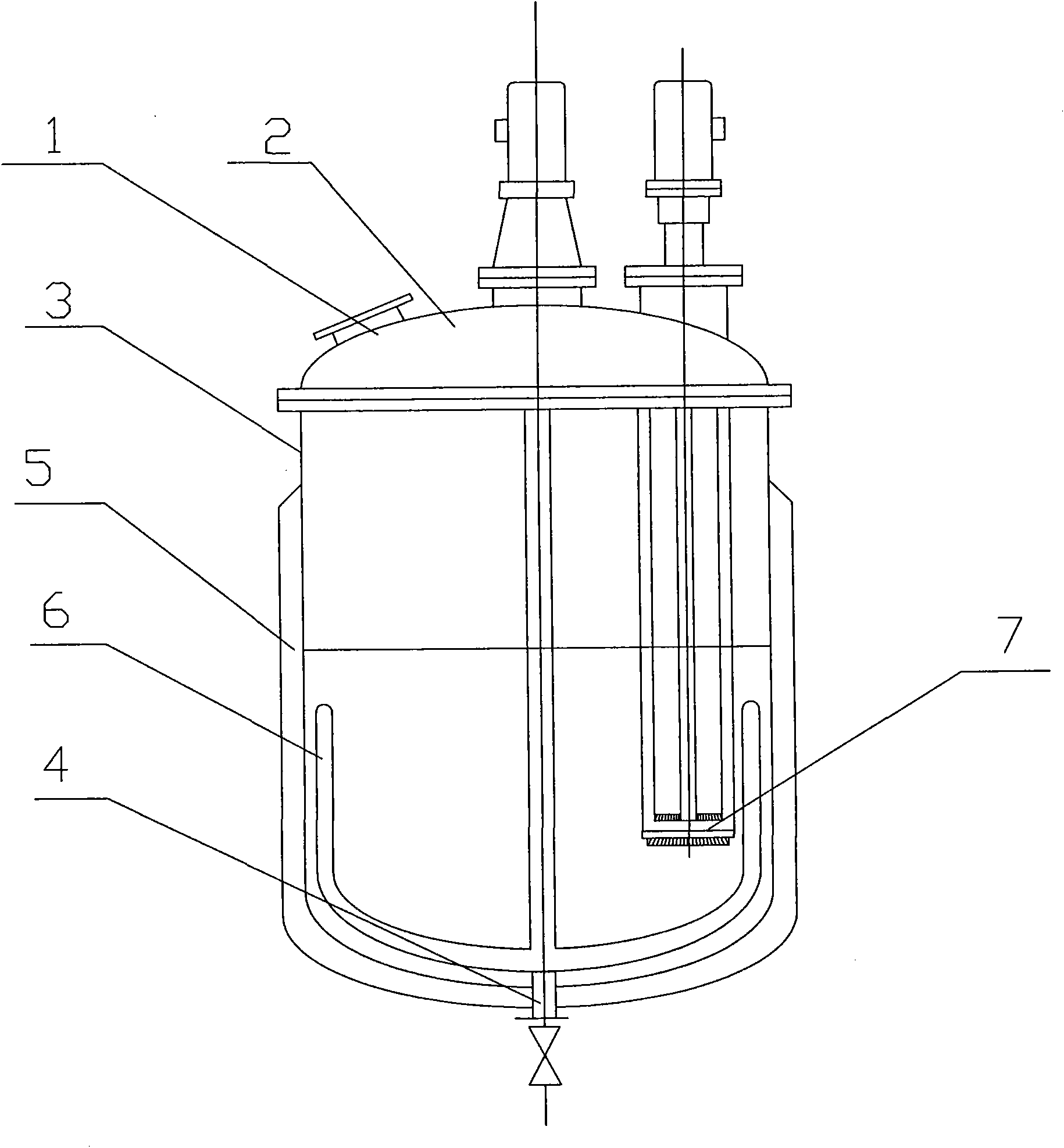

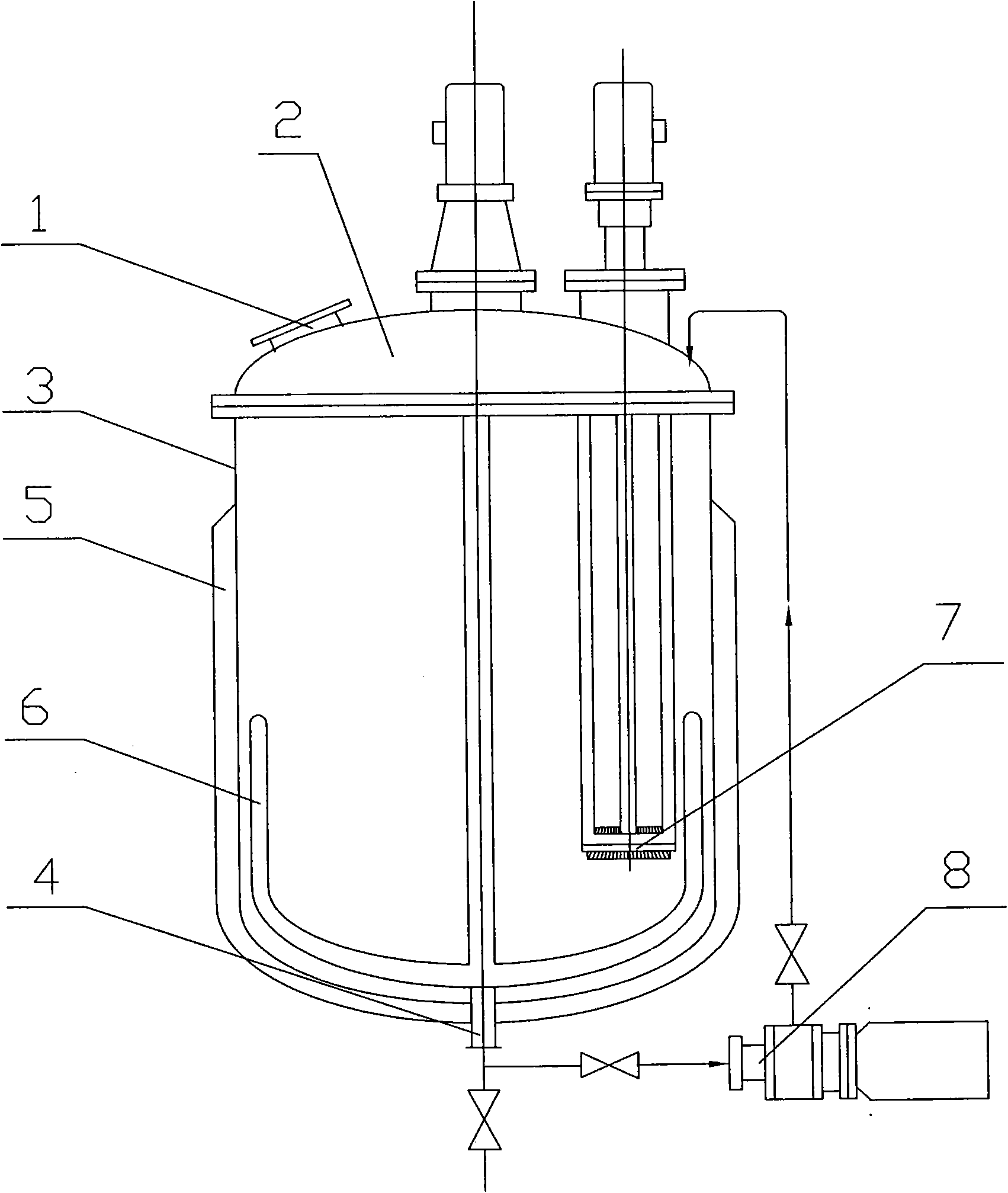

[0040] as attached figure 1 As shown, 150 kg of lauryl alcohol is added into the equipment with agitator 6 and homogenizer 7 through the material inlet 1, and the heating jacket 5 is used to heat up to 40-45 ° C while stirring. Turn on the homogenizer 7, the rotating speed is controlled at 3000rpm, 30kg of phosphorus pentoxide is added in portions, and the adding speed is controlled at 30% of the total amount of phosphorus pentoxide per hour. After the addition, the temperature was raised to 100-105°C, and the reaction was continued for 3h. Then, it is cooled to 50-55°C under stirring with a stirrer, and the material is discharged to obtain lauryl phosphate. The test data are shown in Table 1. In this embodiment, the attached figure 2 And attached image 3 The equipment shown is produced.

Embodiment 2

[0042] as attached figure 1As shown, 150 kg of lauryl alcohol is added into the equipment with agitator 6 and homogenizer 7 through the material inlet 1, and the heating jacket 5 is used to heat up to 40-45 ° C while stirring. Turn on the homogenizer 7, the rotating speed is controlled at 3000rpm, 30kg of phosphorus pentoxide is evenly added, and the adding speed is controlled at 70% of the total amount of phosphorus pentoxide per hour. After the addition, the temperature was raised to 100-105°C, and the reaction was continued for 3h. Then, it is cooled to 50-55°C under stirring with a stirrer, and the material is discharged to obtain lauryl phosphate. The test data are shown in Table 1. In this embodiment, the attached figure 2 And attached image 3 The equipment shown is produced.

Embodiment 3

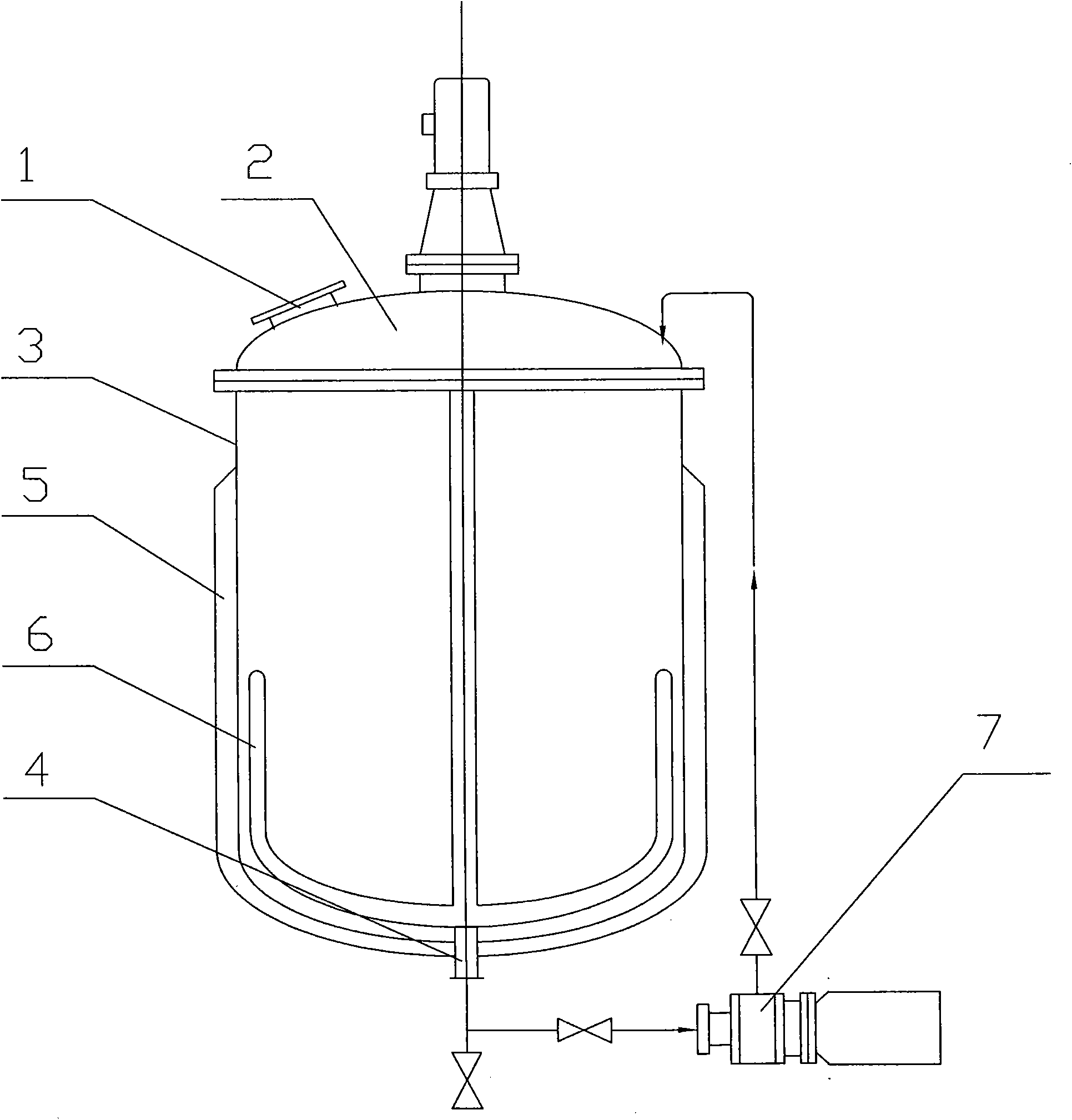

[0044] as attached figure 2 As shown, 150 kg of cetearyl alcohol is added into the equipment with the agitator 6 through the material inlet 1, and the heating jacket 5 is used to heat up to 80-85° C. while stirring. Turn on the homogenizer 7 outside the equipment, control the rotating speed at 1500rpm, and homogenize the material in the equipment through the homogenizer 7; and send the material homogenized by the homogenizer 7 back to the equipment through the pipeline, At the same time, 50kg of polyphosphoric acid is evenly added, and the rate of addition per hour is controlled at 70% of the total amount of polyphosphoric acid. After the addition, the temperature was raised to 135-140°C, and the reaction was continued for 3 hours. Then cool to 70-75°C and discharge under stirring to obtain cetearyl phosphate. The test data are shown in Table 1. In this embodiment, the attached figure 1 And attached image 3 The equipment shown is produced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com