Low-density high-strength ceramic granule propping agent and preparation method thereof

A high-strength ceramsite and proppant technology, applied in the field of fracturing proppant, can solve the problems of unfavorable flow diversion, short support zone, neglect of apparent density, etc., and achieve the effects of shortening the firing cycle, reducing density and rich resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

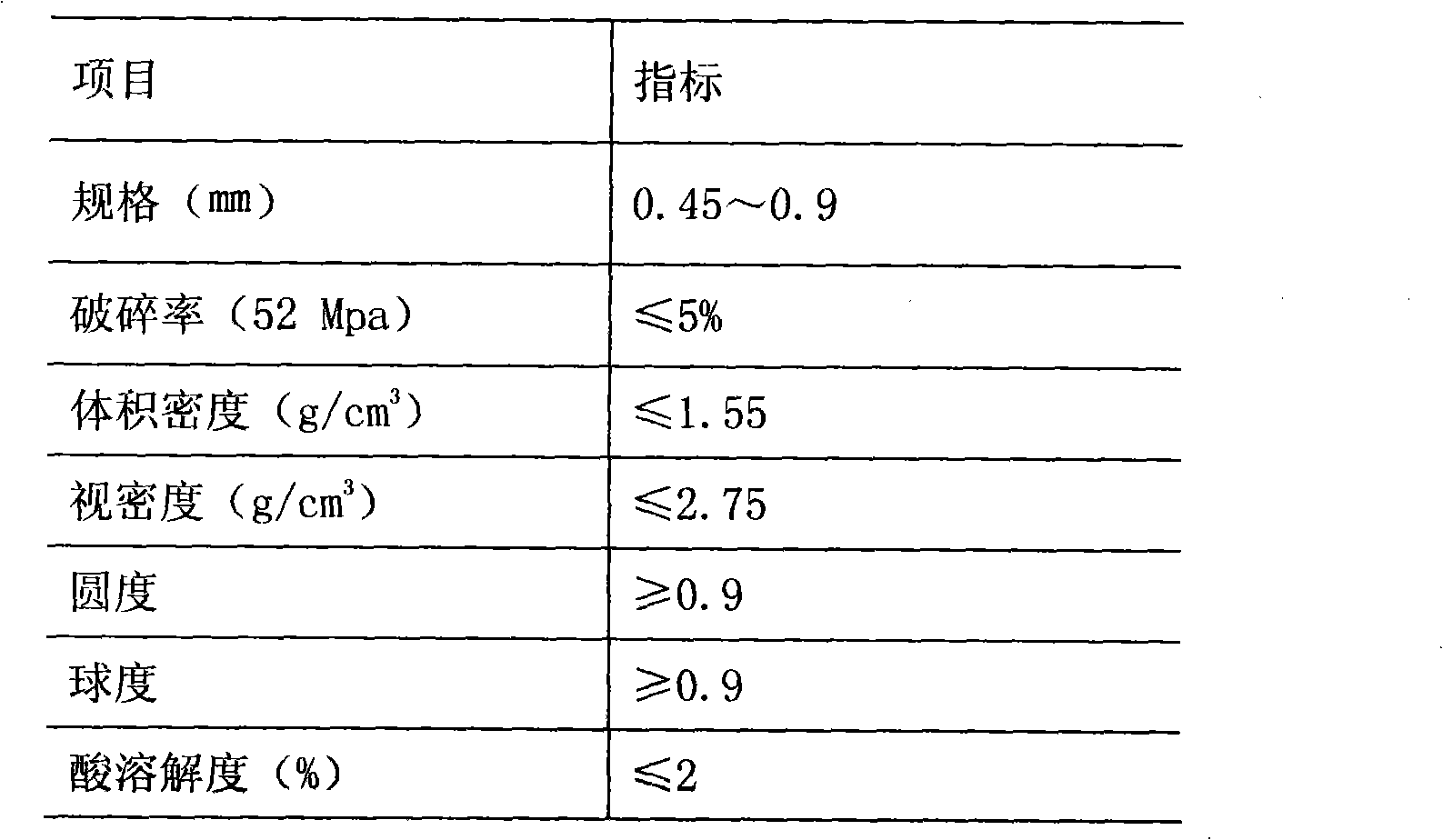

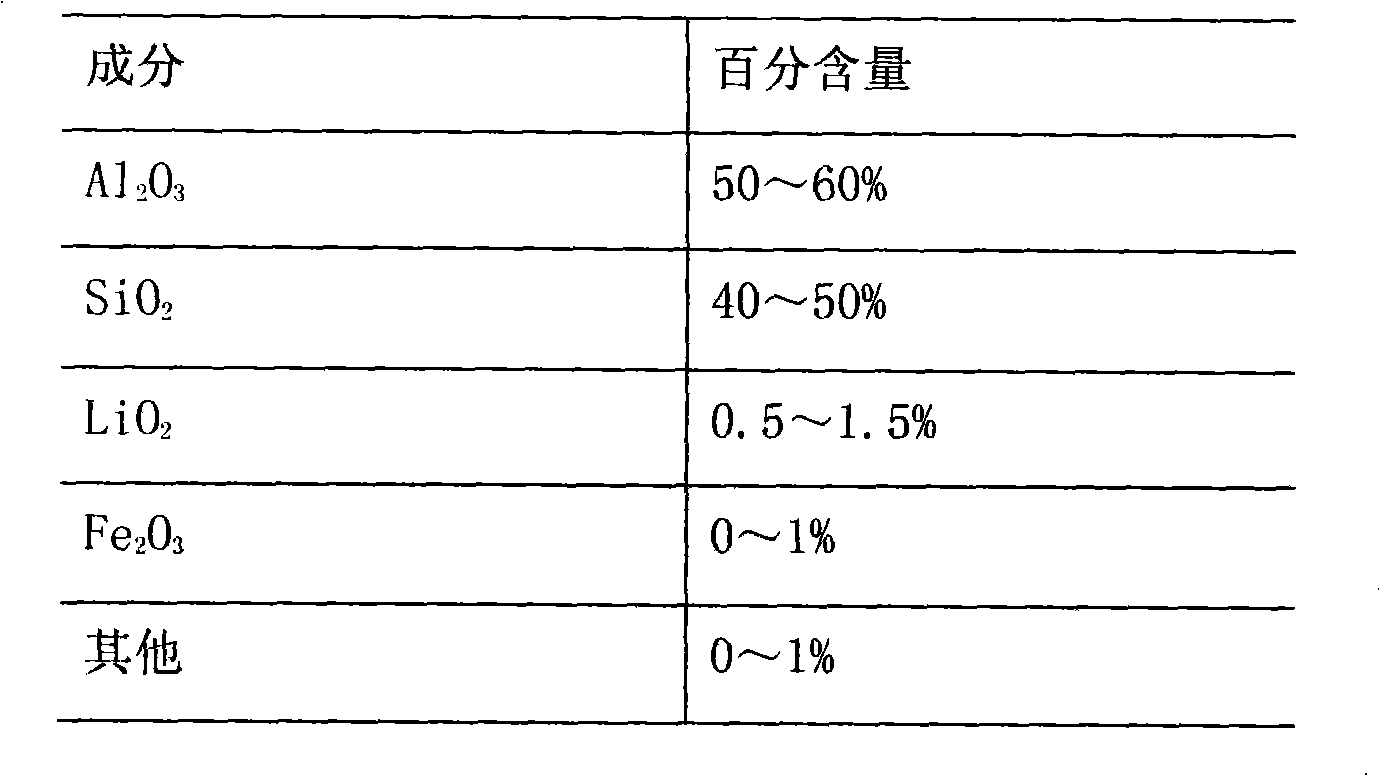

[0034] Example 1 A low-density, high-strength ceramsite proppant is prepared from the following raw materials: 50% of tertiary bauxite, 40% of hard clay, 8% of spodumene, and 2% of industrial starch.

[0035] The preparation method of the above-mentioned low-density high-strength ceramsite proppant comprises the following steps:

[0036] (1) Bauxite and hard clay are lightly burned at 600°C;

[0037] (2) Process the lightly burned bauxite, hard clay and spodumene into 1-3mm lumps through jaw breaking and counter-rolling respectively;

[0038] (3) get bauxite, hard clay, spodumene and industrial starch by the raw material proportioning described in claim 1 and mix into compound;

[0039] (4) Get the mixture obtained in the previous step, mix it with the weight ratio of mixture: grinding medium: water = 1: 2: 0.8, mix it with grinding medium and water, put it in a ball mill for wet grinding for 24 hours, and make the particle size of the mixture reach 5~20um;

[0040] (5) Aft...

Embodiment 2

[0042] Example 2 A low-density, high-strength ceramsite proppant is prepared from the following raw materials: 40% of tertiary bauxite, 55% of tertiary hard clay, 4% of spodumene, and 1% of industrial starch.

[0043] Its preparation method is basically the same as Example 1, the difference is: in the step (4) with the mixing material: grinding medium: water = 1: 2.2: 0.7 weight ratio mixed with grinding medium, quality water, put in ball mill Grind for 20 hours to make the particle size of the mixture reach 10-20um.

Embodiment 3

[0044] Example 3 A low-density, high-strength ceramsite proppant is prepared from the following raw materials: 60% of tertiary bauxite, 30% of tertiary hard clay, 7% of spodumene, and 3% of industrial starch.

[0045] Its preparation method is basically the same as Example 1, the difference is: in the step (4) with the mixture: grinding medium: water = 1: 2: 1 weight ratio mixed with grinding medium, quality water, put in ball mill Grind for 28 hours to make the particle size of the mixture reach 10-15um.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com