Ion implantation method

An ion implantation and ion beam technology, which is used in ion implantation plating, coating, electrical components, etc., can solve the problems of inability to maintain the stability of the ion beam, high difficulty in beam adjustment, and low beam utilization efficiency. Optical properties, reduced overall difficulty, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

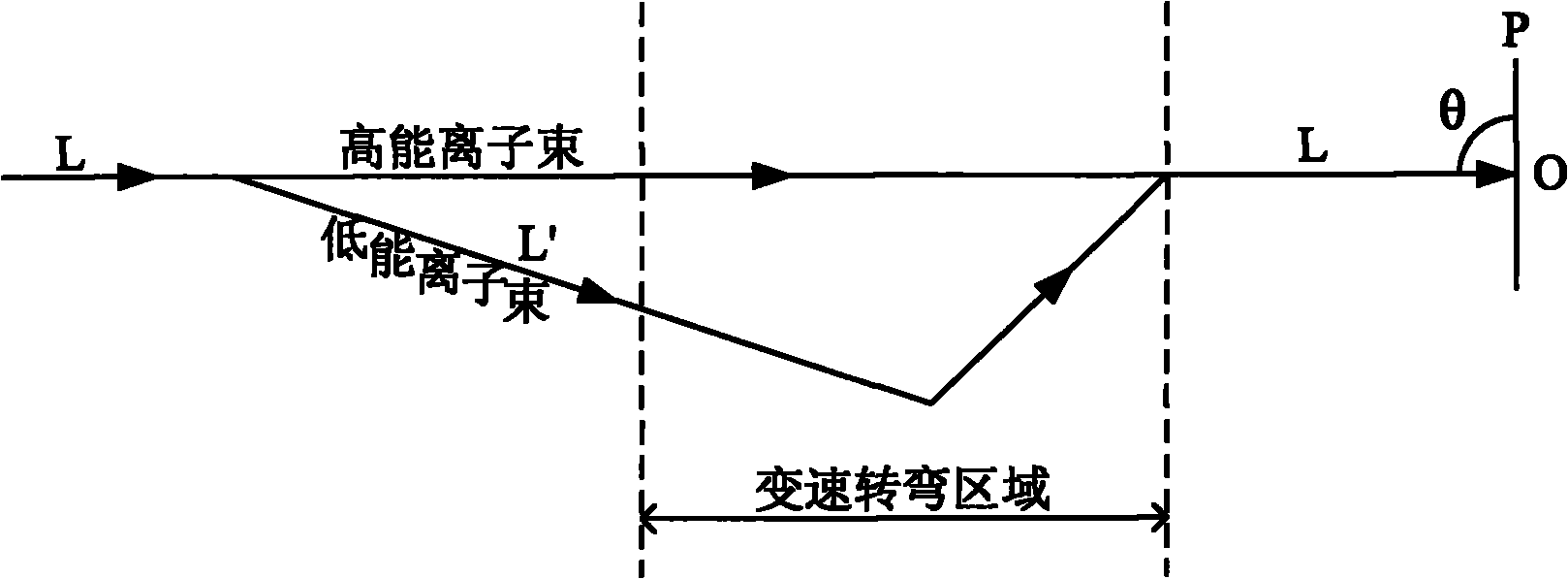

Embodiment 1

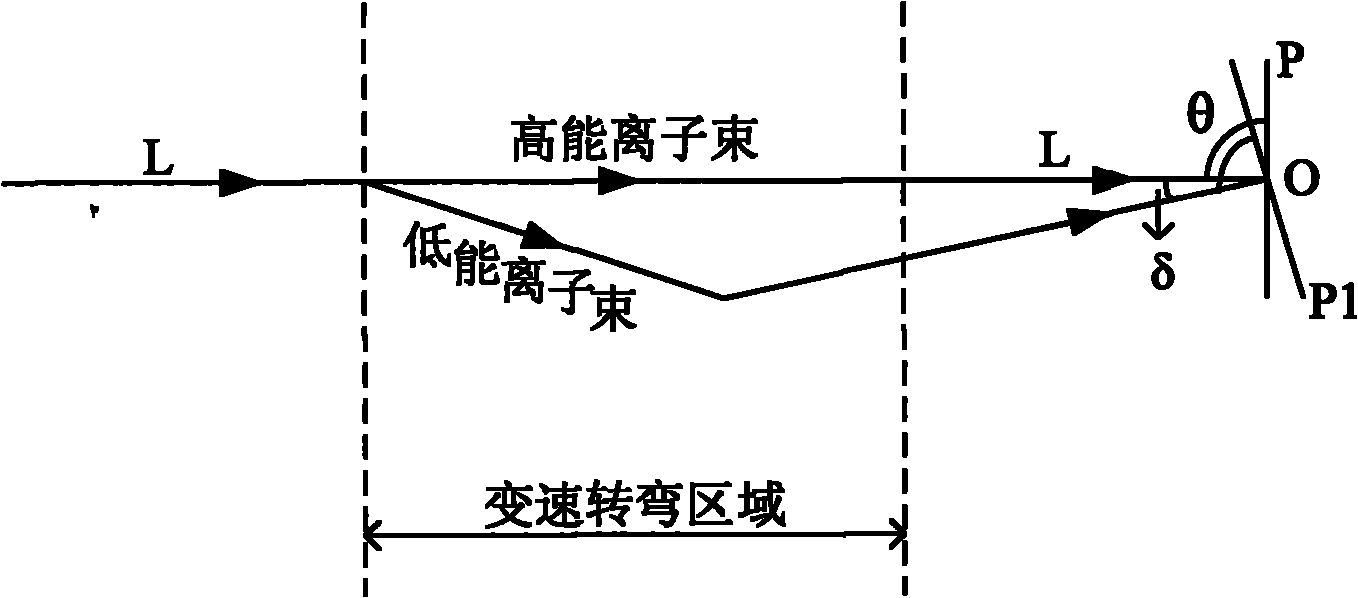

[0023] Such as figure 2 As shown, the low-energy ion beam is deflected at an appropriate angle twice in the variable-speed turning region through the electric effect or magnetic effect, so that it is also at the implantation position O of the workpiece compared with the non-deflected high-energy ion beam , but the implantation angle is deflected by δ. Correspondingly, the workpiece is rotated by the same angle δ to reach the first station P1. The first station P1 enables the low-energy ion beam to remain at the preset incident angle θ at The injection is completed at the injection position O of the workpiece.

Embodiment 2

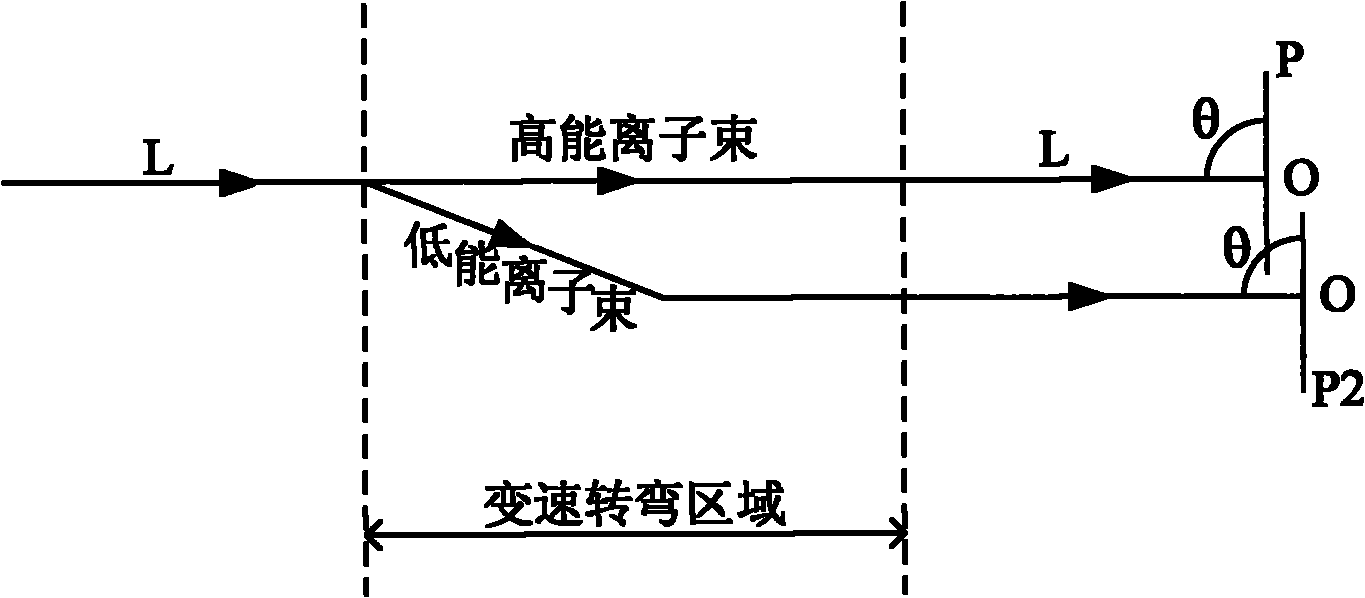

[0025] Such as image 3 As shown, by means of electric effect or magnetic effect, the low-energy ion beam is deflected at an appropriate angle twice in the variable-speed turning region, so that it has the same implantation angle θ compared with the non-deflected high-energy ion beam, but At this time, the alignment is no longer the implantation position O of the workpiece. Correspondingly, the workpiece is translated to the second station P2, and the second station P2 enables the low-energy ion beam to remain at the preset incident angle θ The injection is completed at the injection position O of the workpiece.

Embodiment 3

[0027] Such as Figure 4 As shown, through the electric effect or magnetic effect, the low-energy ion beam is deflected at an appropriate angle in the variable-speed turning area, so that compared with the high-energy ion beam without deflection, not only the implantation angle is deflected, but also the It is no longer aligned with the implantation position O of the workpiece. Correspondingly, the workpiece is rotated angularly and translated to make it reach the third station P3. The third station P3 enables the low-energy ion beam to still maintain the The preset incident angle θ completes the implantation at the implantation position O of the workpiece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com