Silicon controlled rectifier electro-static discharge protective circuit structure triggered by diode

A technology for protecting circuits and electrostatic discharge, which is applied in the electronic field and can solve problems such as unfavorable protection of internal circuit devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

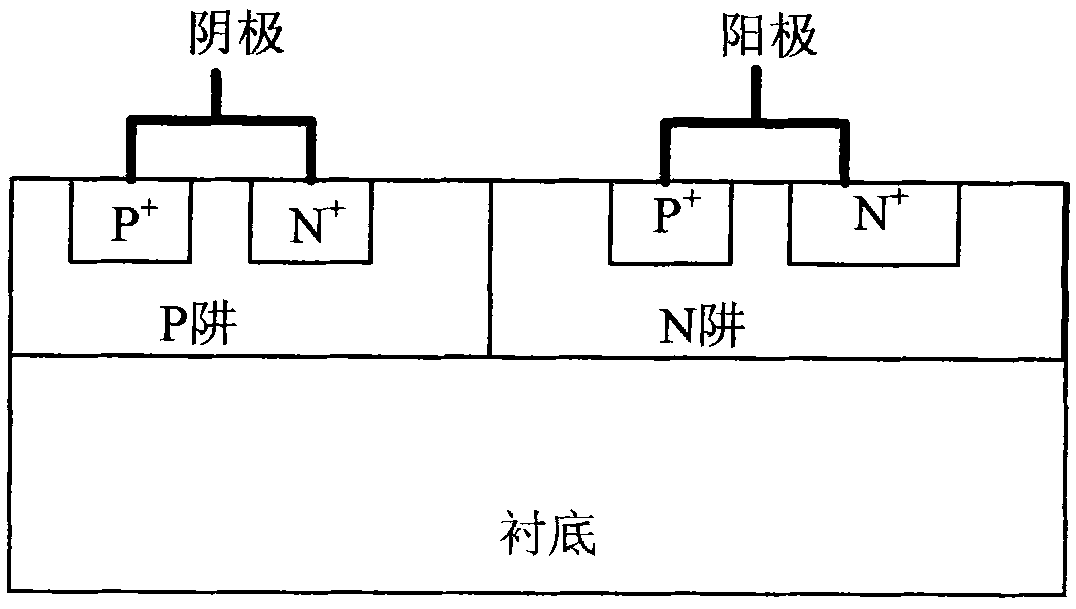

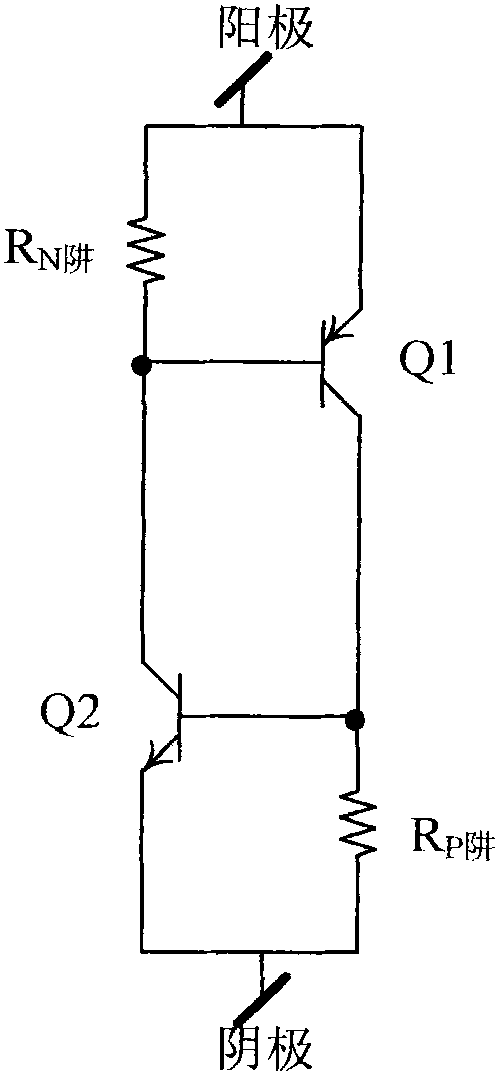

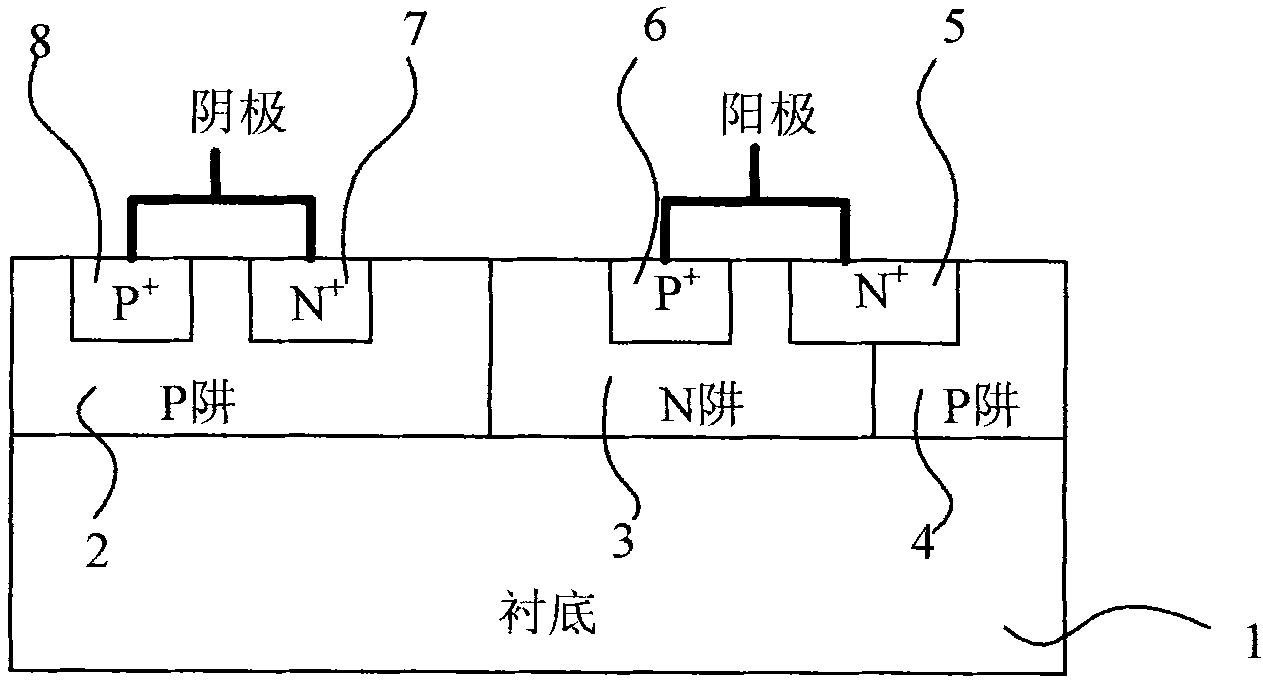

[0024] A diode-triggered thyristor rectifier electrostatic discharge protection circuit structure, such as image 3 As shown, it includes: two conductivity types of well regions located on the semiconductor substrate substrate 1: P-type well region 2 and N-type well region 3; two heavily doped well regions located in the first P-type well region 2 District: P + heavily doped region 8 and N + Heavily doped region 7; two heavily doped regions located in N-type well region 3: P + heavily doped region 6 and N + The heavily doped region 5 ; the cathode contacting the surfaces of the two heavily doped regions in the first P-type well region 2 ; the anode contacting the surfaces of the two heavily doped regions in the N-type well region 3 . The protection circuit structure also includes a second P-type well region 4, the second P-type well region 4 is connected to the first P-type well region 2 and surrounds the N-type well region 3 in the middle, and the N-type well region N in ...

specific Embodiment approach 2

[0028] A diode-triggered thyristor rectifier electrostatic discharge protection circuit structure, such as Figure 5 As shown, it includes: two conductivity types of well regions located on the semiconductor substrate substrate 1: N-type well region 2 and P-type well region 3; two heavily doped well regions located in the first N-type well region 2 District: N + Zone 8 and P + Open region 7; two heavily doped regions located in the P-type well region 3: N + Zone 6 and P + Region 5; an anode in contact with the surfaces of the two heavily doped regions in the first N-type well region 2; a cathode in contact with the surfaces of the two heavily doped regions in the P-type well region 3. The protection circuit structure also includes a second N-type well region 4, the second N-type well region 4 is connected to the first N-type well region 2 and surrounds the P-type well region 3 in the middle, and the P-type well region P in zone 3 + A part of the region 5 is located in the...

specific Embodiment approach 3

[0032] Such as Figure 8 As shown, on the basis of the technical solution of Embodiment 1, a P well not connected to the existing two heavily doped regions is added in the first P-type well region 2. + Heavily doped region 9, while adding a P well not connected to the existing heavily doped region in the second P-type well region 4 + heavily doped region 10; and the two increased P + The heavily doped regions 9 and 10 are interconnected by metal wires.

[0033] When adding two P + After the heavily doped regions 9 and 10, in the case of parasitic diode breakdown, the hole current is mainly composed of P + Heavily doped region 10, and flows to P through the wire + The heavily doped region 9 flows through the P-type well region 2 to the N in the P-type well region 2 + The heavily doped region 7 is finally collected by the cathode electrode. This can make the hole current distribution more uniform, so as to form a uniform voltage drop on the P well, so as to avoid the inhom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com