Lithium titanate/carbon/carbon nano tube composite electrode material and preparation method thereof

A technology of carbon nanotubes and composite electrodes, which can be used in battery electrodes, circuits, capacitors, etc., and can solve problems such as poor conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

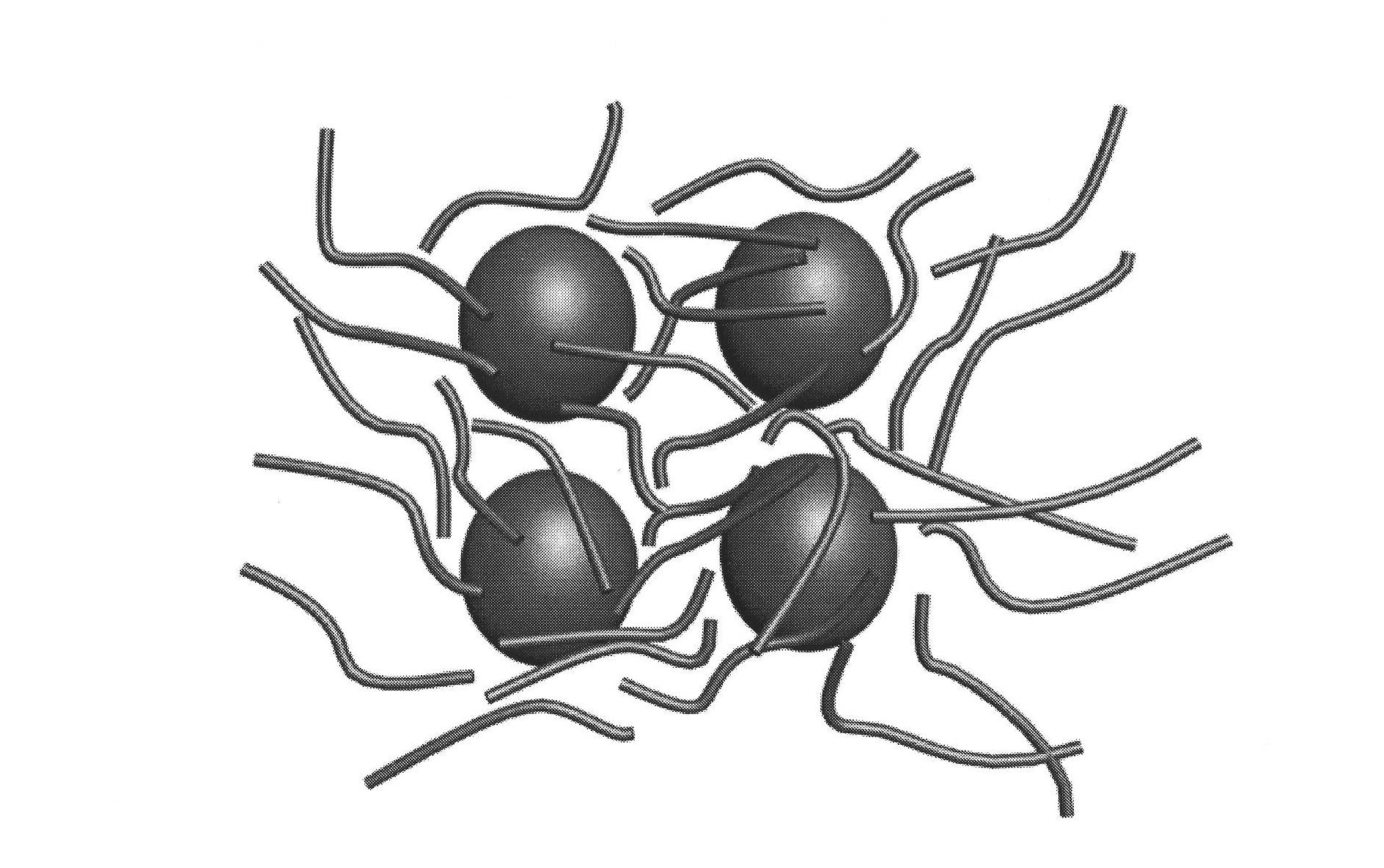

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

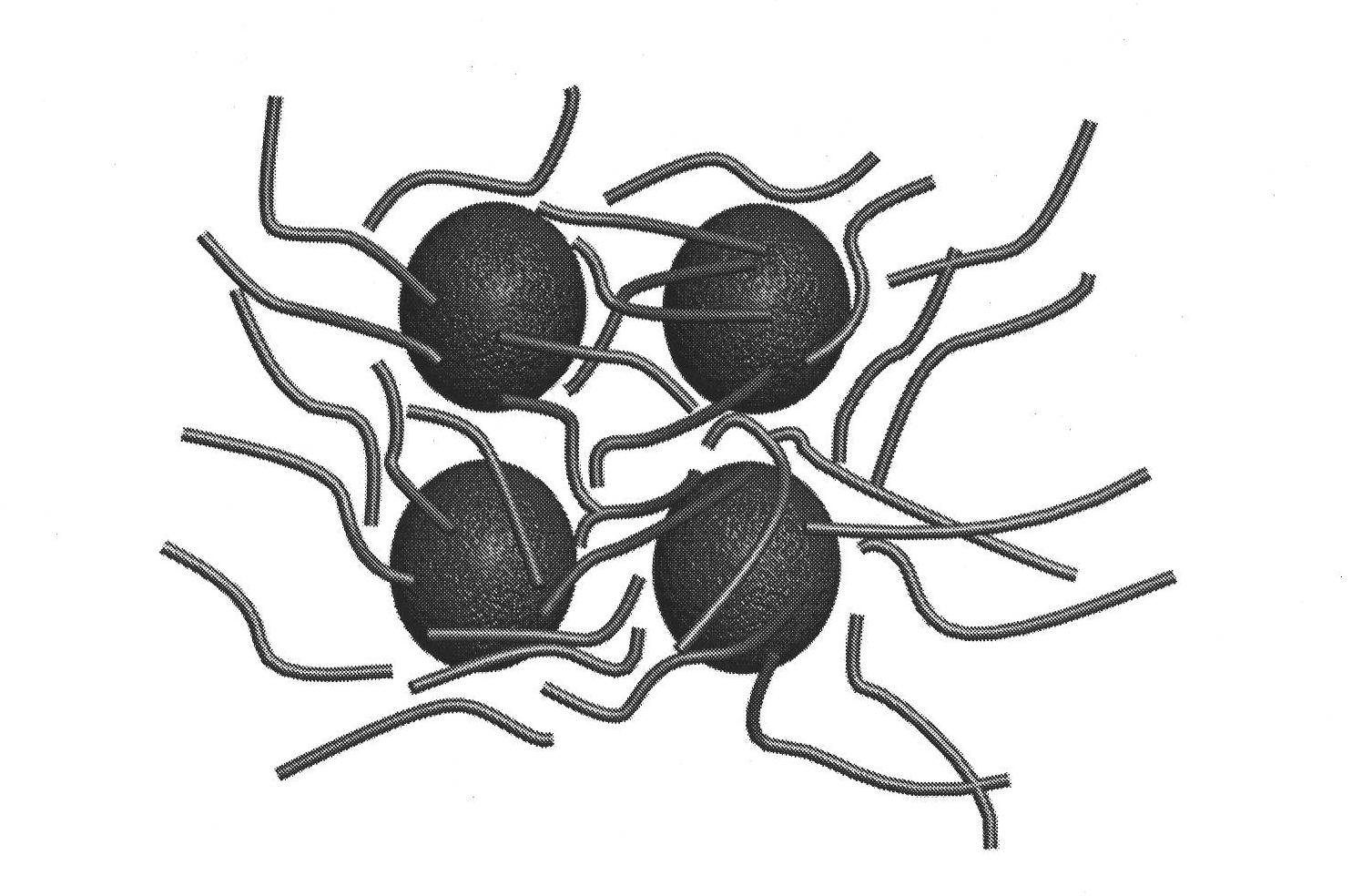

Embodiment 1

[0027] Weigh 4.0gCH 3 COOLi.2H2 O was placed in a beaker, and about 20ml of deionized water was added to prepare solution A with a concentration of about 2mol / L. Then weigh 0.14g of carbon nanotubes and 0.035g of PVP and put them into another beaker, add about 150ml of deionized water and undergo sufficient ultrasonic treatment to obtain solution B. Add solution A dropwise to solution B under stirring conditions to prepare a new mixed solution C. Weigh a certain amount of anatase titanium dioxide according to the ratio of lithium to titanium molar ratio of 4:5 and add it to the above mixed solution C. The solution C is stirred at 80°C until dry, ground, and heat-treated at 800°C for 12 hours in an inert atmosphere. A spinel lithium titanate / carbon nanotube composite was obtained. Weigh 0.80g of the sample, mix the sample powder, acetylene black and LA-132 at a ratio of 85:10:5 to make an electrode sheet, which is used as a positive electrode after vacuum drying, and a lithiu...

Embodiment 2

[0029] Weigh 4.0gCH 3 COOLi.2H 2 O was placed in a beaker, and about 20ml of deionized water was added to prepare solution A with a concentration of about 2mol / L. Then weighed 0.24g of carbon nanotubes and 0.06g of PVP and put them into another beaker, added about 150ml of deionized water and underwent sufficient ultrasonic treatment to obtain solution B. Add solution A dropwise to solution B under stirring conditions to prepare a new mixed solution C. Weigh a certain amount of anatase titanium dioxide according to the ratio of lithium to titanium molar ratio of 4:5 and add it to the above mixed solution C. The solution C is stirred at 80°C until dry, ground, and heat-treated at 800°C for 12 hours in an inert atmosphere. A spinel lithium titanate / carbon nanotube composite was obtained. Weigh 0.80g of the sample, mix the sample powder, acetylene black and LA-132 at a ratio of 8.5:1:0.5 to make an electrode sheet, which is used as a positive electrode after vacuum drying, and...

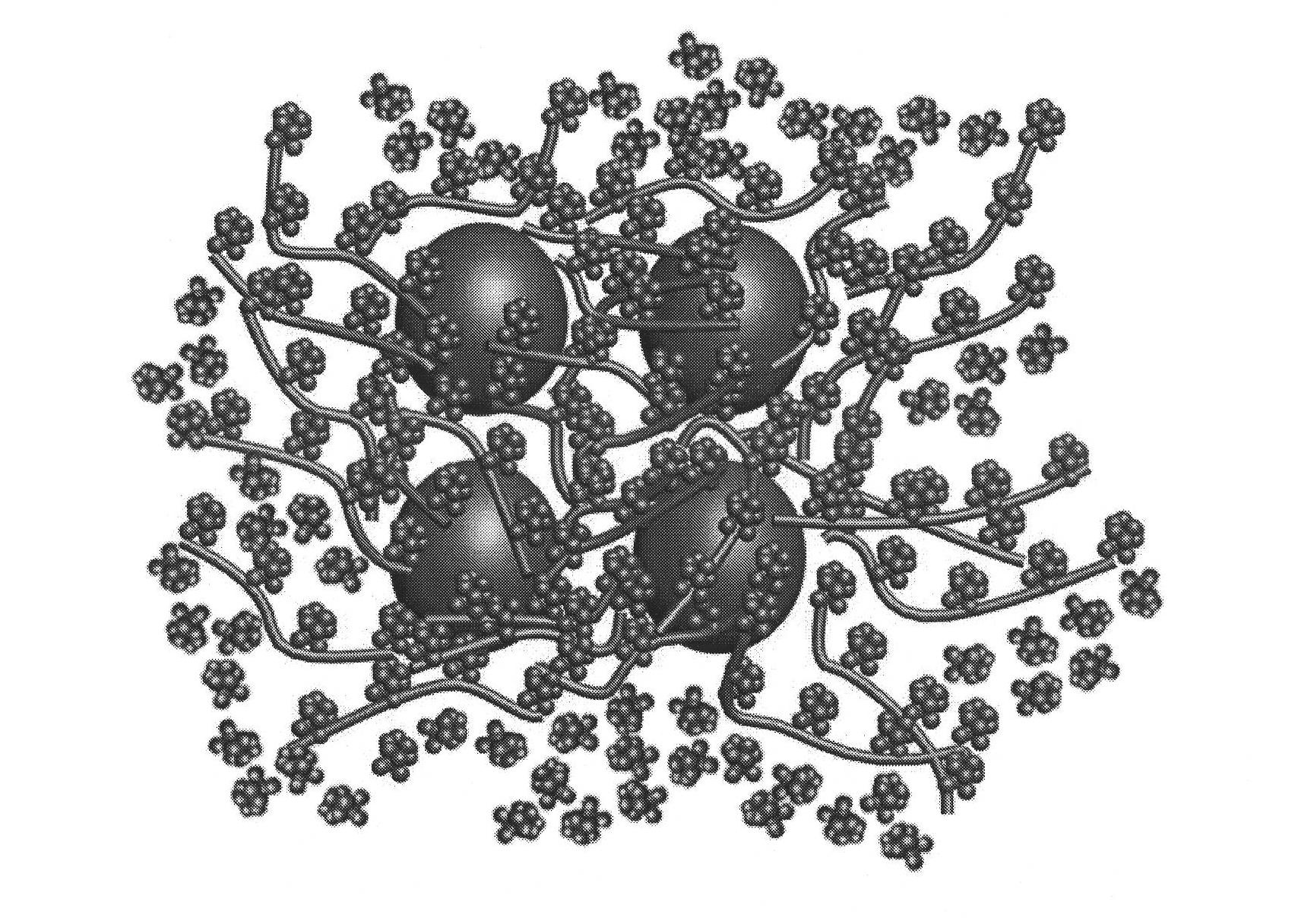

Embodiment 3

[0031] Weigh 4.0gCH 3 COOLi.2H 2 O was placed in a beaker, and about 20ml of secondary deionized water was added to prepare solution A with a concentration of about 2mol / L. Then weigh 0.14g of carbon nanotubes and 0.035g of PVP respectively and put them into another beaker, add about 150ml of secondary deionized water and undergo sufficient ultrasonic treatment to obtain solution B. Add solution A dropwise to solution B under stirring conditions to prepare a new mixed solution C. Weigh a certain amount of anatase titanium dioxide according to the ratio of lithium to titanium molar ratio of 4:5 and add it to the above mixed solution C. The solution C is stirred at 80°C until dry, ground, and heat-treated at 800°C for 12 hours in an inert atmosphere. A spinel lithium titanate / carbon nanotube composite was obtained. Weigh 2.0g of the above product, dissolve it in a solution containing 0.2g sucrose, stir it at 70-80°C to dryness, grind it, and heat it at 800°C for 2 hours in an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com