Influenza virus vaccine using nanometer emulsion as adjuvant and method for preparing same

An influenza virus and nanoemulsion technology, applied in antiviral agents, medical preparations containing active ingredients, pharmaceutical formulations, etc., can solve the problem of limited immunogenicity enhancement of vaccines, and achieve enhanced bioavailability and dosage. Small, fluid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A. Dilute the stock solution of influenza virus vaccine with water for injection to a hemagglutinin concentration of 30 μg / (strain.ml), to obtain the diluted influenza virus vaccine;

[0034] B, prepare materials according to the following mass ratio: 10g of diluted influenza virus vaccine, 50g of isopropyl myristate, 20g of 1,2-propanediol, and 20g of Tween80;

[0035] C. Add 20g Tween80 and 20g 1,2-propylene glycol into the mixing and stirring bottle, and continue to stir at a temperature of 60°C. The rotating speed is maintained at 50 rpm, and then 50g isopropyl myristate is added to obtain a mixed solution;

[0036] D. Slowly drop the diluted influenza virus vaccine of step A into the above mixed solution, while maintaining the rotation speed at 50 rpm, stir until the liquid is transparent, and obtain the influenza virus vaccine with nanoemulsion as adjuvant.

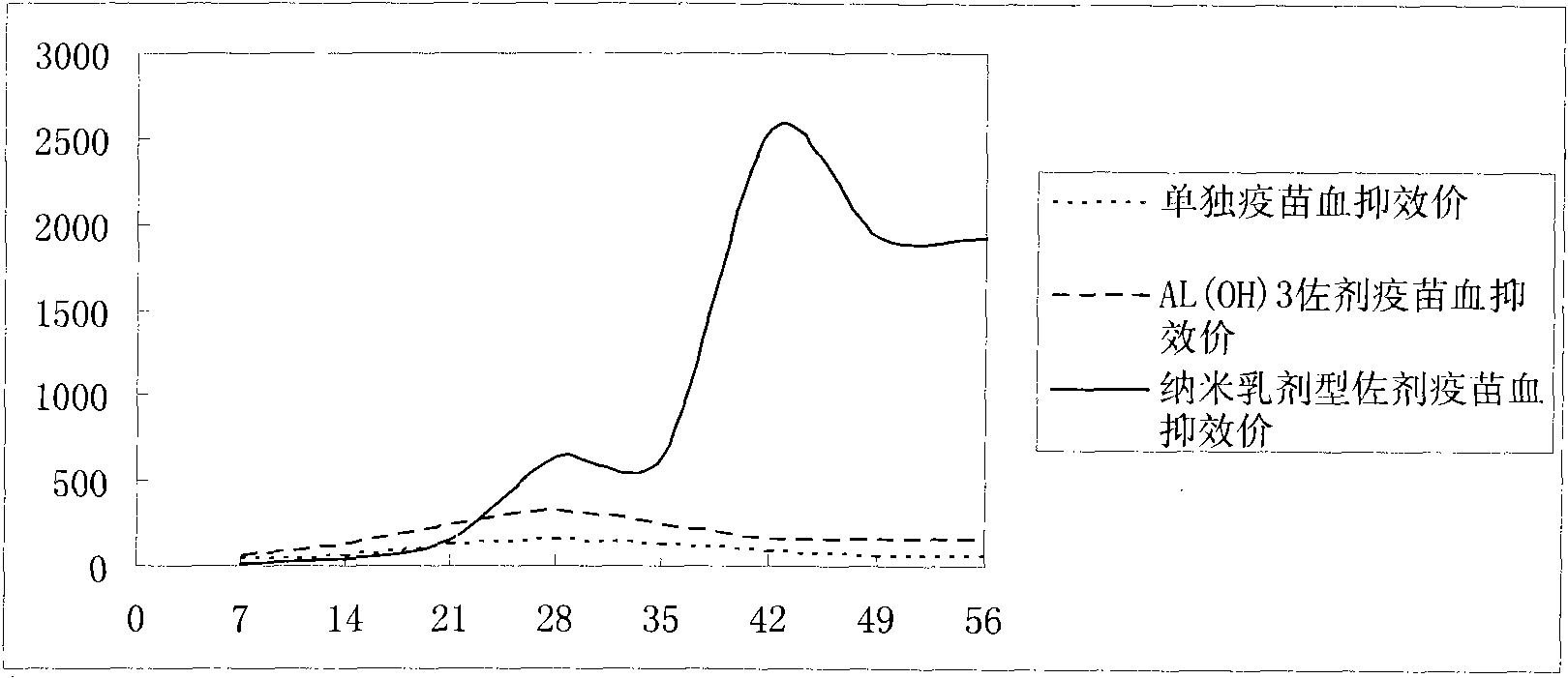

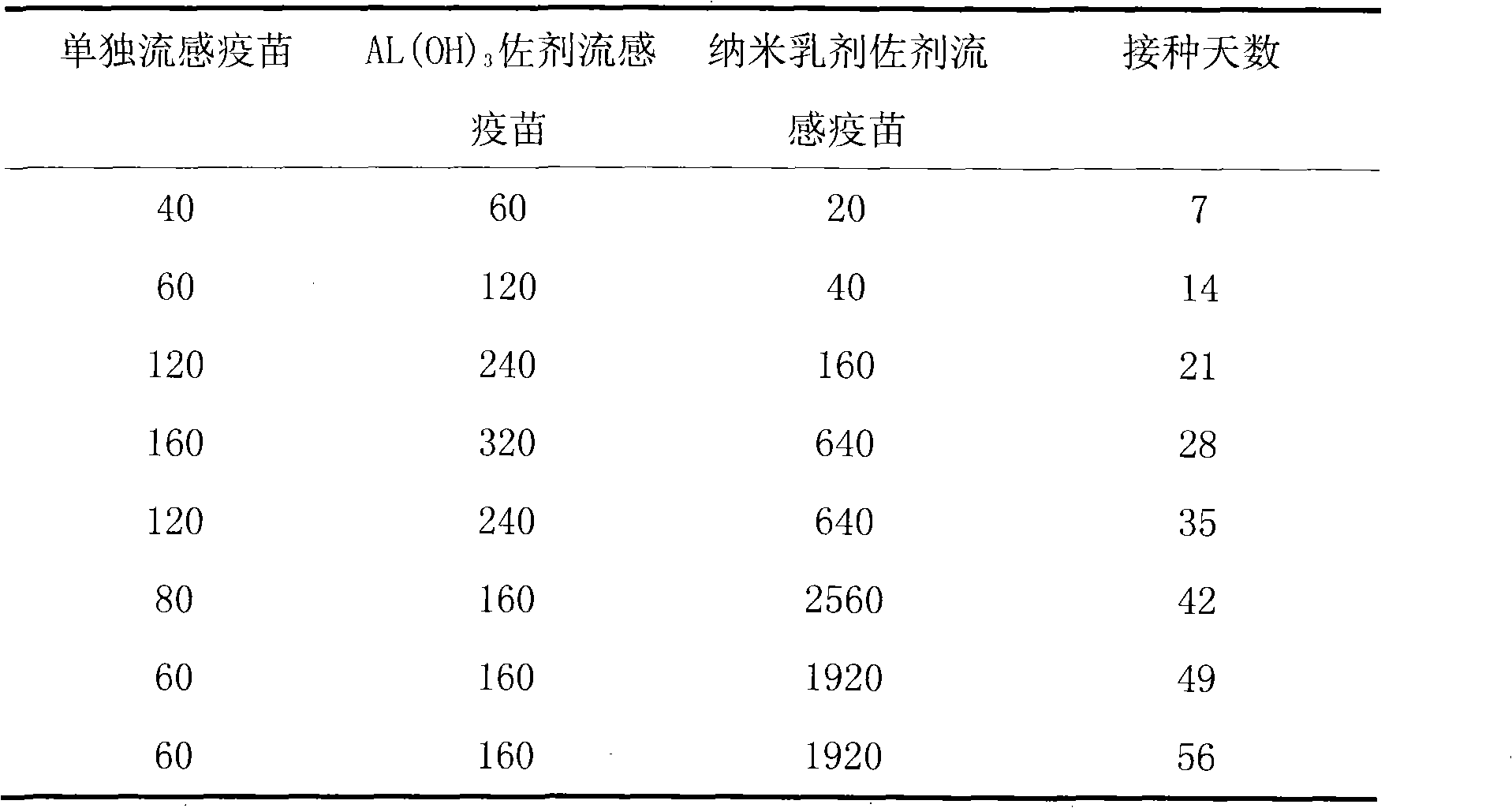

[0037] The prepared influenza virus vaccine is tested as follows: 1. Detected by a Malvern particle size d...

Embodiment 2

[0039] A, dilute the stock solution of influenza virus vaccine with water for injection to a hemagglutinin concentration of 15 μg / (strain.ml), to obtain the diluted influenza virus vaccine;

[0040] B, prepare raw materials according to the following mass ratio: 30g diluted influenza virus vaccine, 30g soybean oil for injection, 20g polyethylene glycol 400, 12g Tween80, 8g Span80;

[0041] C. Add 12g Tween80 and 8g Span80 and 20g Polyethylene Glycol 400 in the mixing and stirring bottle, keep stirring at a temperature of 20°C, and keep the rotating speed at 500 rpm, then add 30g soybean oil for injection to obtain a mixture;

[0042] D. Slowly drop the diluted influenza virus vaccine into the above mixture, while maintaining the rotating speed at 500 rpm, stir until the liquid is transparent, and obtain the influenza virus vaccine with the nanoemulsion as an adjuvant.

[0043] The prepared influenza virus vaccine is tested as follows: 1. Detected by a Malvern particle size det...

Embodiment 3

[0045] A. Dilute the influenza virus vaccine stock solution with water for injection to a hemagglutinin concentration of 50 μg / (strain.ml);

[0046] B, prepare raw materials according to the following mass ratio: 20g diluted influenza virus vaccine, 20g soybean oil for injection, 40g polyethylene glycol 400, 8g Tween80, 12g Span80;

[0047] C. Add 8g Tween80, 12g Span80, 40g Polyethylene Glycol 400 to the mixing and stirring bottle, keep stirring at 40°C, keep the rotating speed at 200 rpm, then add 20g soybean oil for injection to obtain the mixture;

[0048] D. Slowly drop the diluted influenza virus vaccine into the above mixture while maintaining the rotating speed at 200 rpm, and stir until the liquid is transparent to obtain the influenza virus vaccine with the nanoemulsion as an adjuvant.

[0049] The prepared influenza virus vaccine is tested as follows: 1. Detected by a Malvern particle size detector, the particle size range is 18.906~24.854nm, qualified; 2. Through 400...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com