Combined collector for floatation of porphyry copper-molybdenum mine and floatation method thereof

A combined collector and porphyry copper technology is applied in the combined collector and flotation field of porphyry copper-molybdenum ore flotation, which can solve the problems of molybdenite loss and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

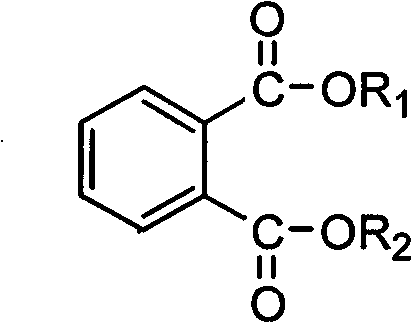

[0031] at 1m 3 Add 650 parts of diethyl phthalate into the reaction kettle, add 350 parts of N-ethoxycarbonyl-N'-propylthiourea under stirring, and stir at room temperature for 30 minutes to obtain a light yellow oily liquid, which can be used directly Copper flotation collector for porphyry copper-molybdenum ore, code name BS-1.

Embodiment 2

[0033] at 1.5m 3 Add 380 parts of diethyl phthalate and 600 parts of diesel oil to the reaction kettle, add 20 parts of N-ethoxycarbonyl N'-propylthiourea under stirring, and stir at room temperature for 60 minutes to obtain a light yellow oily liquid, the product It can be directly used as a collector for molybdenum-copper flotation of porphyry copper-molybdenum ore, code name BSH-2.

Embodiment 3

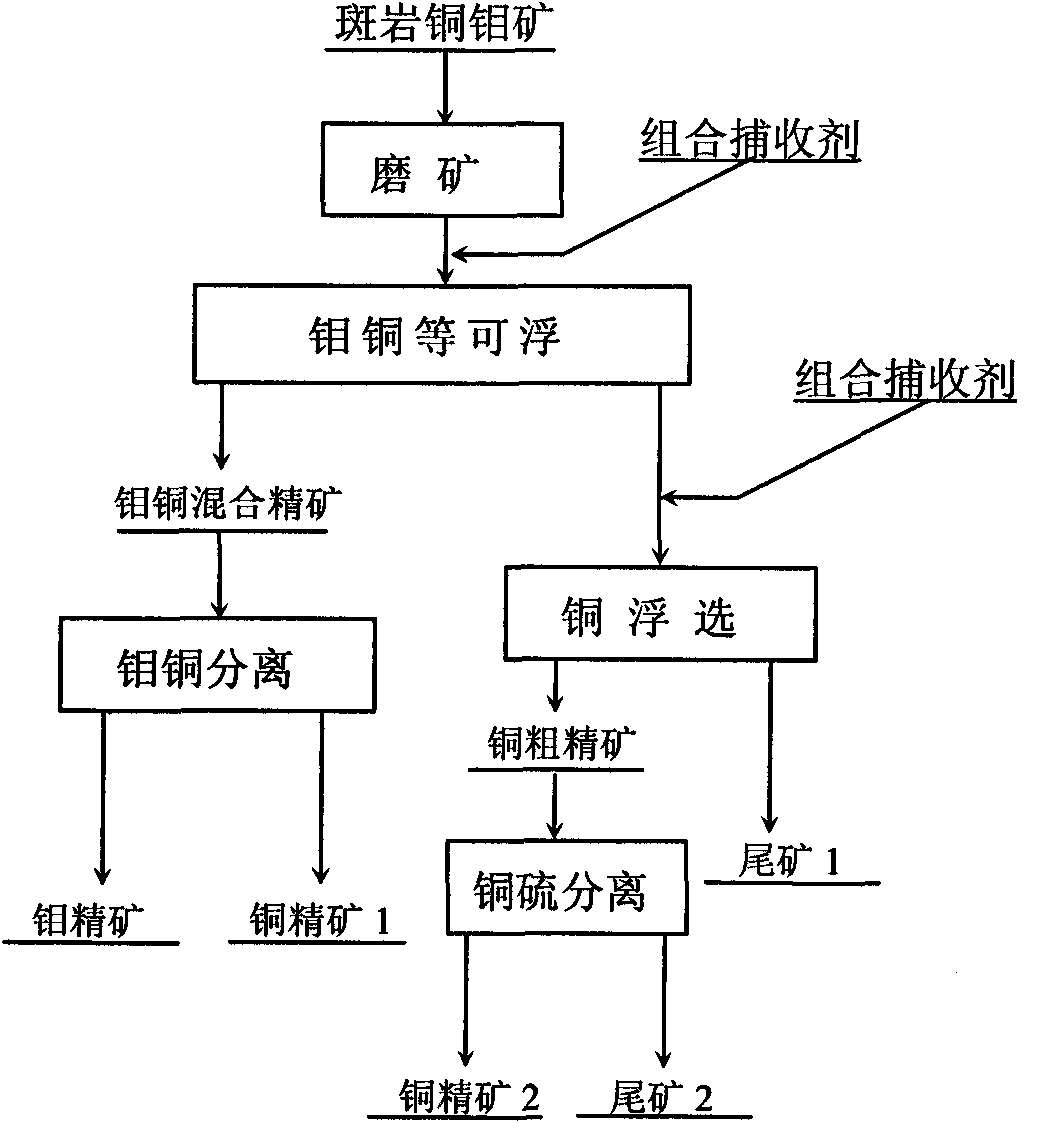

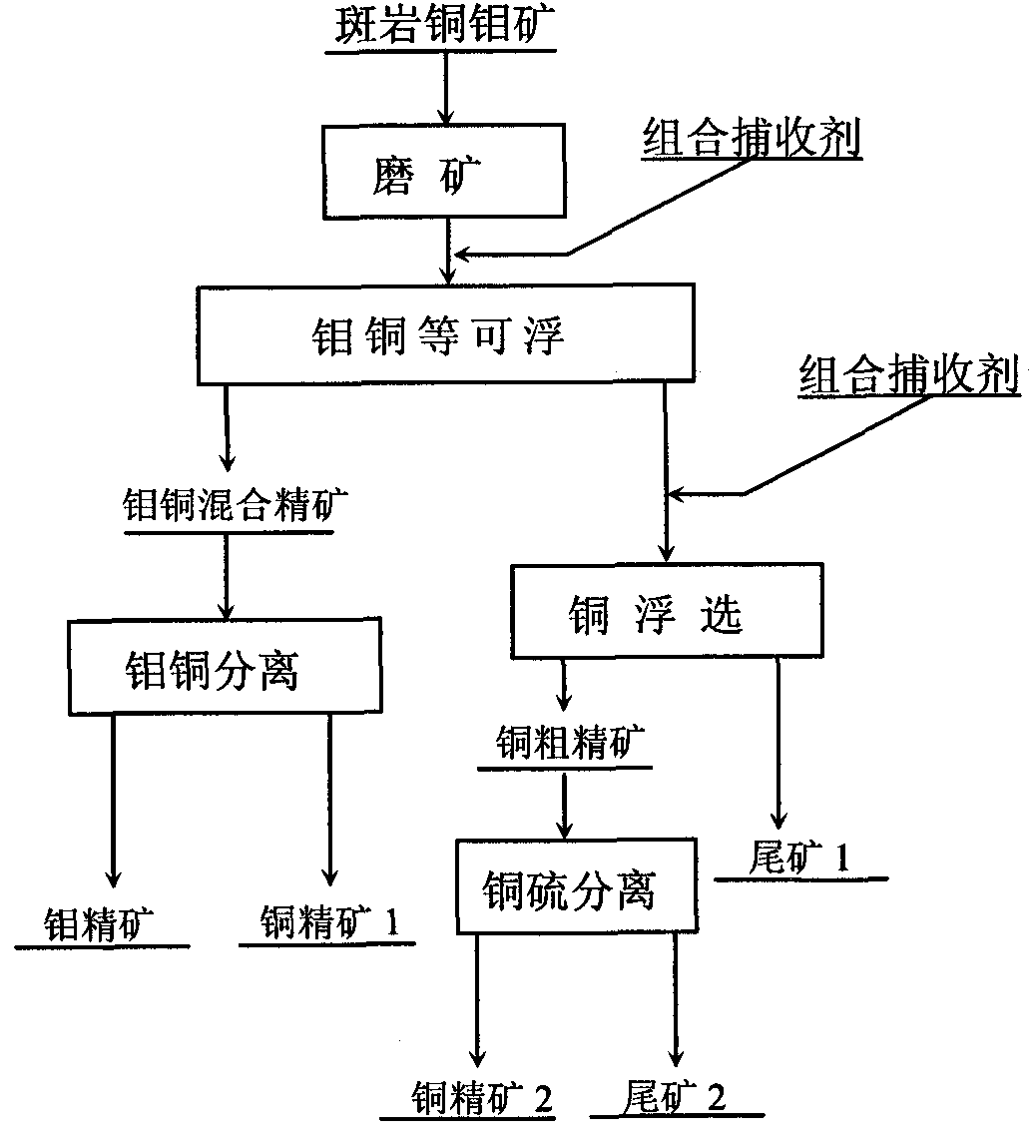

[0035] A large porphyry copper-molybdenum deposit, the main metal sulfide minerals in the ore are chalcopyrite, bornite, molybdenite, pyrite and a small amount of pyrrhotite. Gangue minerals mainly include quartz, juan mica, chlorite, water muscovite, illite, biotite and so on. The raw ore contains 0.44% copper, 0.0077% molybdenum, 1.21% sulfur, and the copper oxidation rate is 4.52%.

[0036] The ore sample is crushed to -2mm into a ball mill, the grinding concentration is 62%, and the grinding fineness is -200 mesh, accounting for 65%. The concentration of the flotation pulp is 30%, the pH value is adjusted to 7.5 with lime, and a collector is added for a rough separation. The flotation test conditions and results are shown in Table 1.

[0037] Table 1 Comparison test results of flotation collectors for porphyry copper-molybdenum ore

[0038]

[0039] * BSH-2 is the combination collector of embodiment 1 of the present invention

[0040]It can be seen from Table 1 that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com