Buffer area facing coating or assemble production line

A buffer and production line technology, applied in the directions of transportation and packaging, conveyor objects, motor vehicles, etc., can solve problems such as inability to meet at the same time, different times, etc., to achieve a simple and easy control method, shorten the sorting path, and improve efficiency and stability. Sexual Level Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and example the present invention is described in further detail.

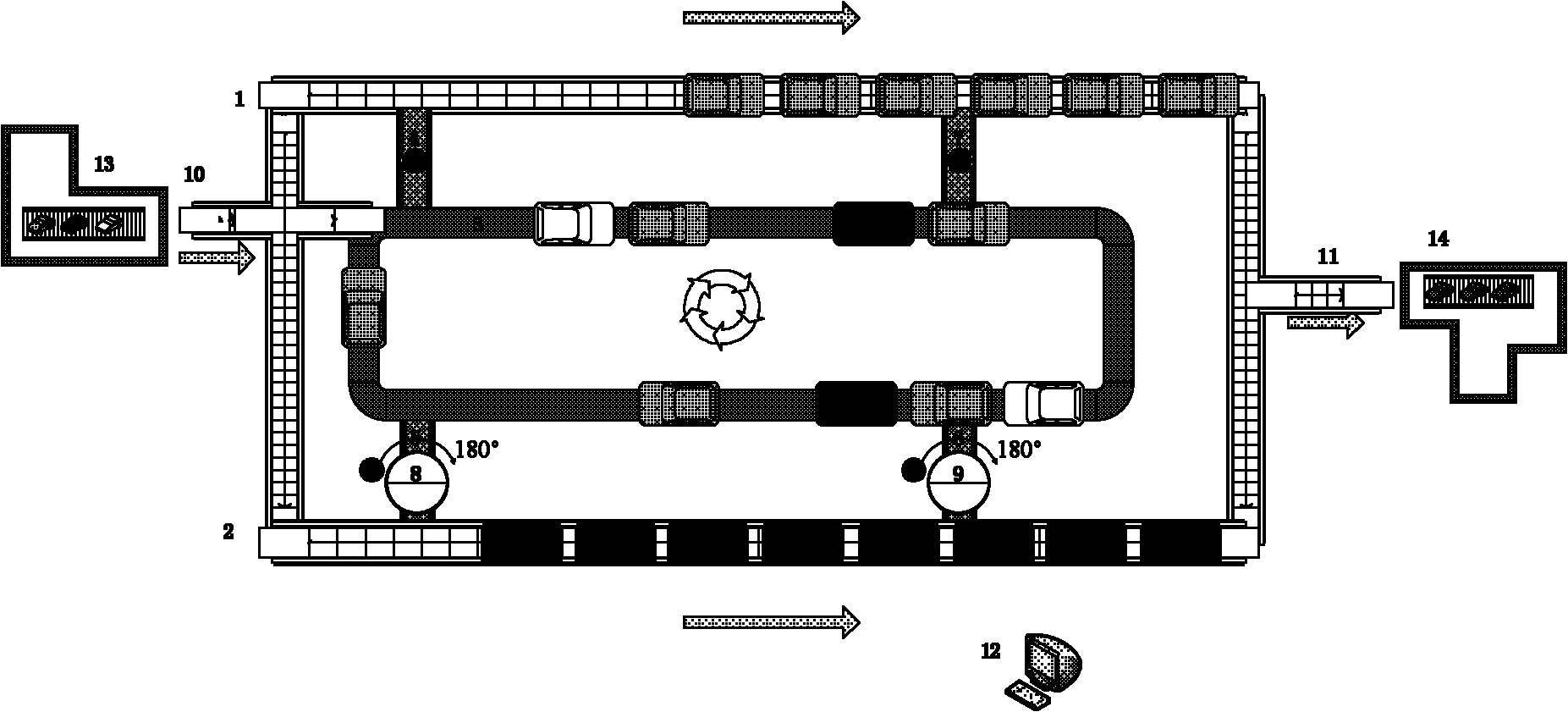

[0020] Such as figure 1 Shown, buffer zone structure of the present invention comprises conveyer belt 1,2, buffer zone 3, carrying belt 4,5,6,7, steering wheel 8,9, enter buffer zone identifier 10, go out buffer zone identifier 11, buffer zone Visualization controller 12, upstream production line 13 and downstream production line 14.

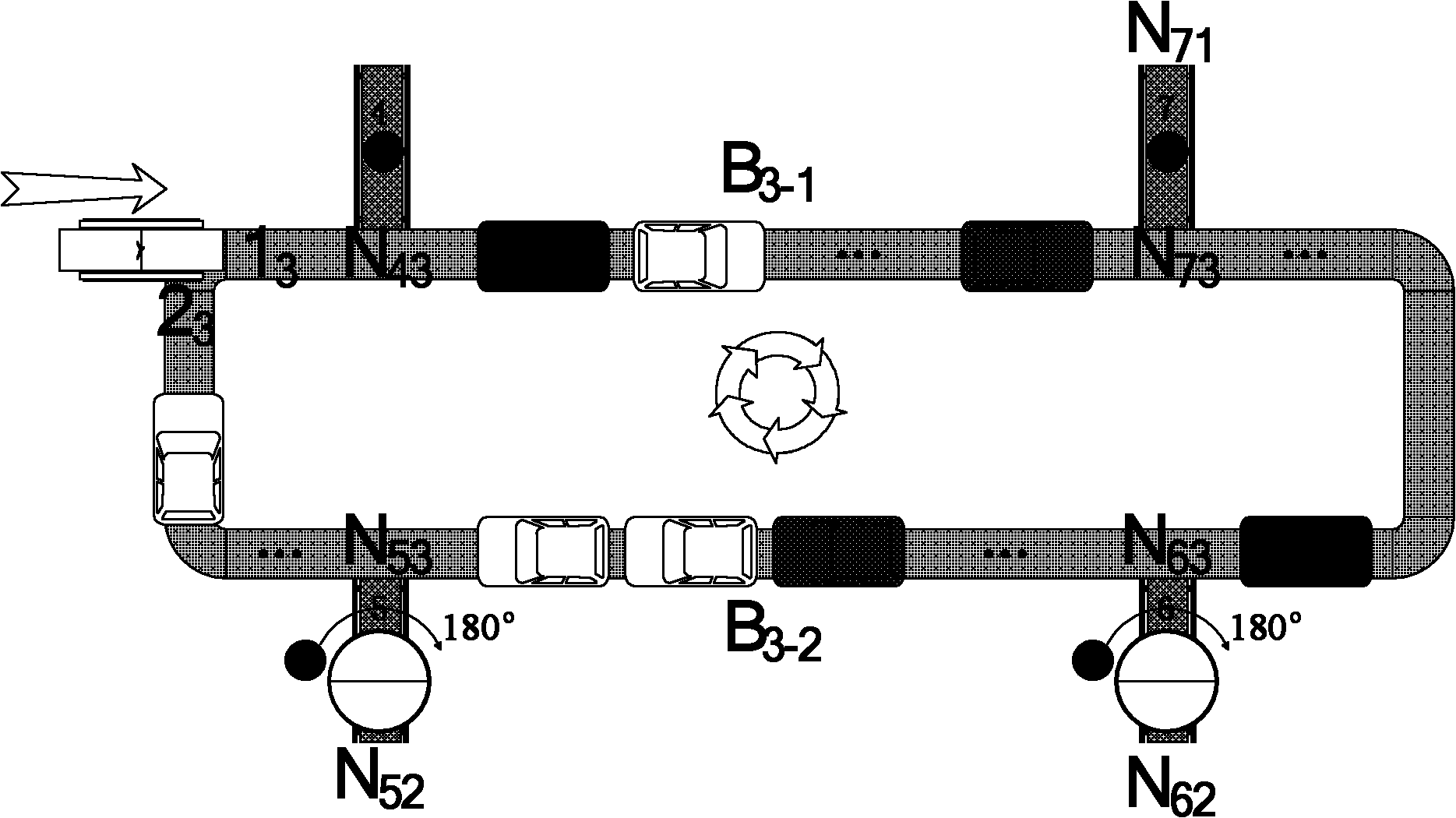

[0021] Conveyor belts 1 and 2 are respectively located on both sides of the buffer zone, connecting the upstream and downstream production lines, each with a power traction device, and each with Nc (Nc is a positive integer) storage positions, that is, each conveyor belt can accommodate a maximum of Nc number of car bodies , there is no empty storage location between any non-empty storage location on the conveyor belt and the buffer exit, that is, if the first n (0≤n≤Nc-1, and it is a positive integer) storage locations on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com