Composite barium strontium titanate ceramics and preparation method thereof

A technology of composite titanium and ceramics, which is applied in the field of ceramic materials, can solve the problems of reduced adjustability of BSTO materials, increased energy consumption of devices, and reduced dielectric constant of materials, etc., and achieves stable and reliable preparation processes, low dielectric loss, and low The effect of dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

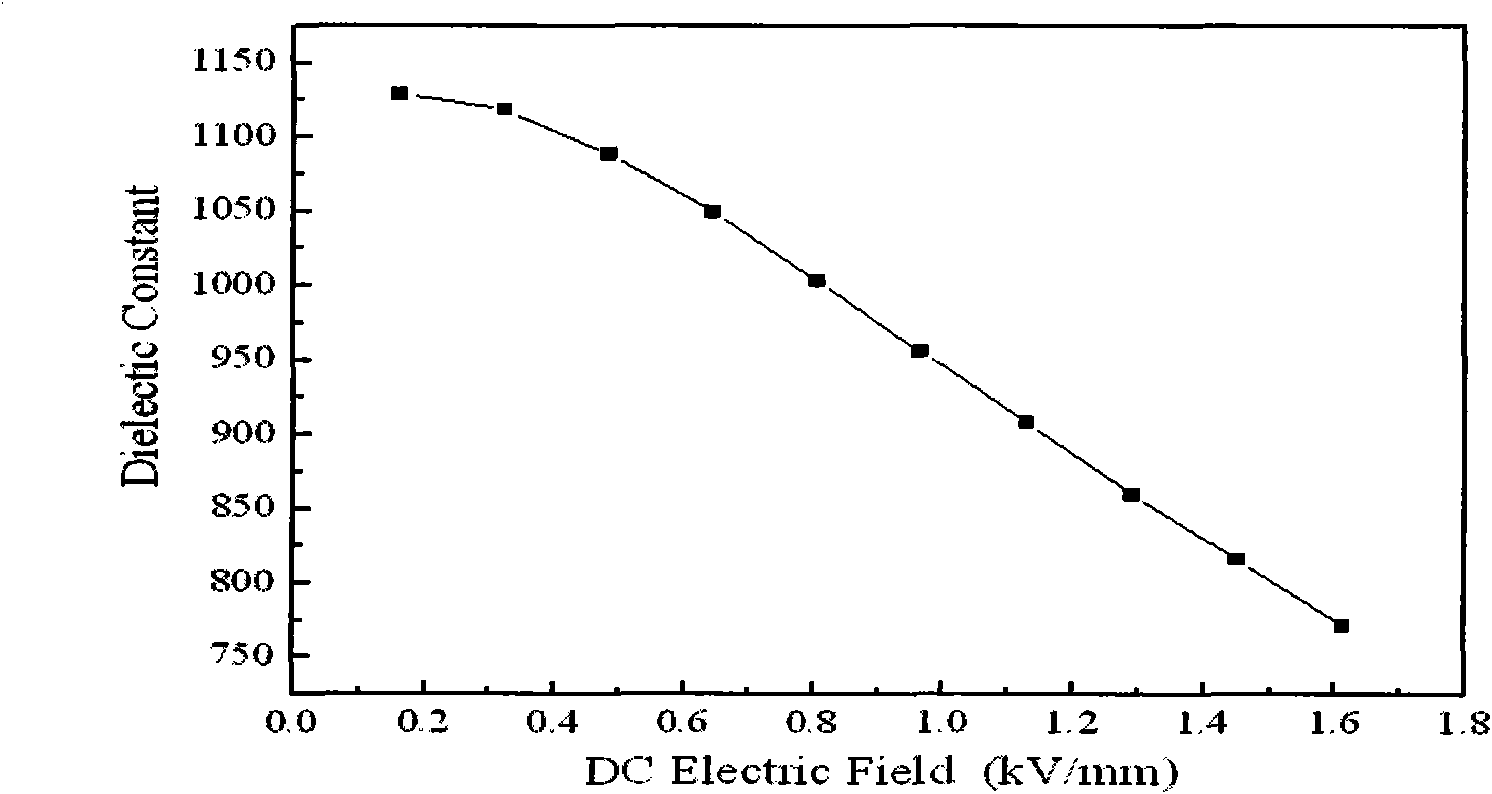

[0028] This embodiment is to prepare 100 g of ceramic materials with an adjustability of 29%.

[0029] In this embodiment, BaCO with a purity of 99.8%, 99.0% and 98.5% respectively 3 , SrCO 3 and TiO 2 Prepared Ba 0.6 Sr 0.4 TiO 3 As the matrix material, ZnO and Al with a purity of 99.0%, 98.0% and 98.0% are added in combination 2 o 3 and MgO, whose composition is Ba 0.6 Sr 0.4 TiO 3 +xZnO+yAl 2 o 3 +10 wt% MgO, where x=0.5 wt%, y=10 wt%.

[0030] The concrete preparation steps of this embodiment are:

[0031] The first step, prepare Ba 0.6 Sr 0.4 TiO 3 Calcined powder; the BaCO 3 , SrCO 3 and TiO 2 Press Ba 0.6 Sr 0.4 TiO 3 Stoichiometric batching, adding 80ml of absolute ethanol medium to the batching, and ball milling for 12h to obtain a slurry; drying the slurry at 100°C for 6h to obtain a powder; pre-calcining the obtained powder at 1050°C for 4h to obtain Ba 0.6 Sr 0.4 TiO 3 Pre-fired powder;

[0032] The second step is to prepare the oxide compo...

Embodiment 2

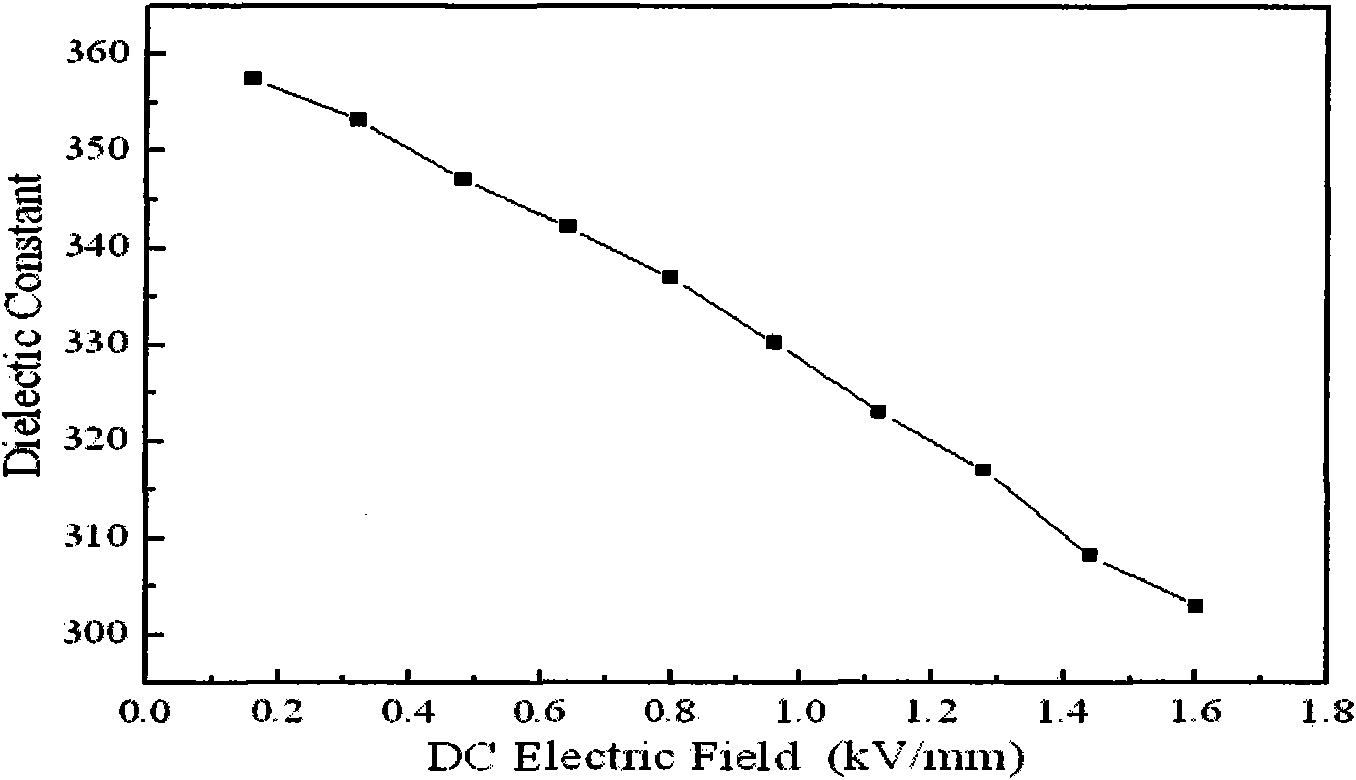

[0037] In this embodiment, 80 g of ceramic materials with an adjustability of 18% are prepared.

[0038] In this embodiment, BaCO with a purity of 99.0%, 98.0% and 98.0% respectively 3 , SrCO 3 and TiO 2 Prepared Ba 0.6 Sr 0.4 TiO 3 As the matrix material, ZnO and Al with a purity of 98.5%, 99.0% and 99.0% are added in combination 2 o 3 and MgO, whose composition is Ba 0.6 Sr 0.4 TiO 3 +xZnO+yAl 2 o 3 +10 wt% MgO, where x=5 wt%, y=30 wt%.

[0039] The concrete preparation steps of this embodiment are:

[0040] The first step, prepare Ba 0.6 Sr 0.4 TiO 3 Calcined powder; the BaCO 3 , SrCO 3 and TiO 2 Press Ba 0.6 Sr 0.4 TiO 3 Stoichiometric batching, adding 60ml of absolute ethanol medium to the batching, and ball milling for 16h to obtain a slurry; drying the slurry at 80°C for 8h to obtain a powder; pre-calcining the obtained powder at 1100°C for 3h to obtain Ba 0.6 Sr 0.4 TiO 3 Pre-fired powder;

[0041] The second step is to prepare the oxide compos...

Embodiment 3

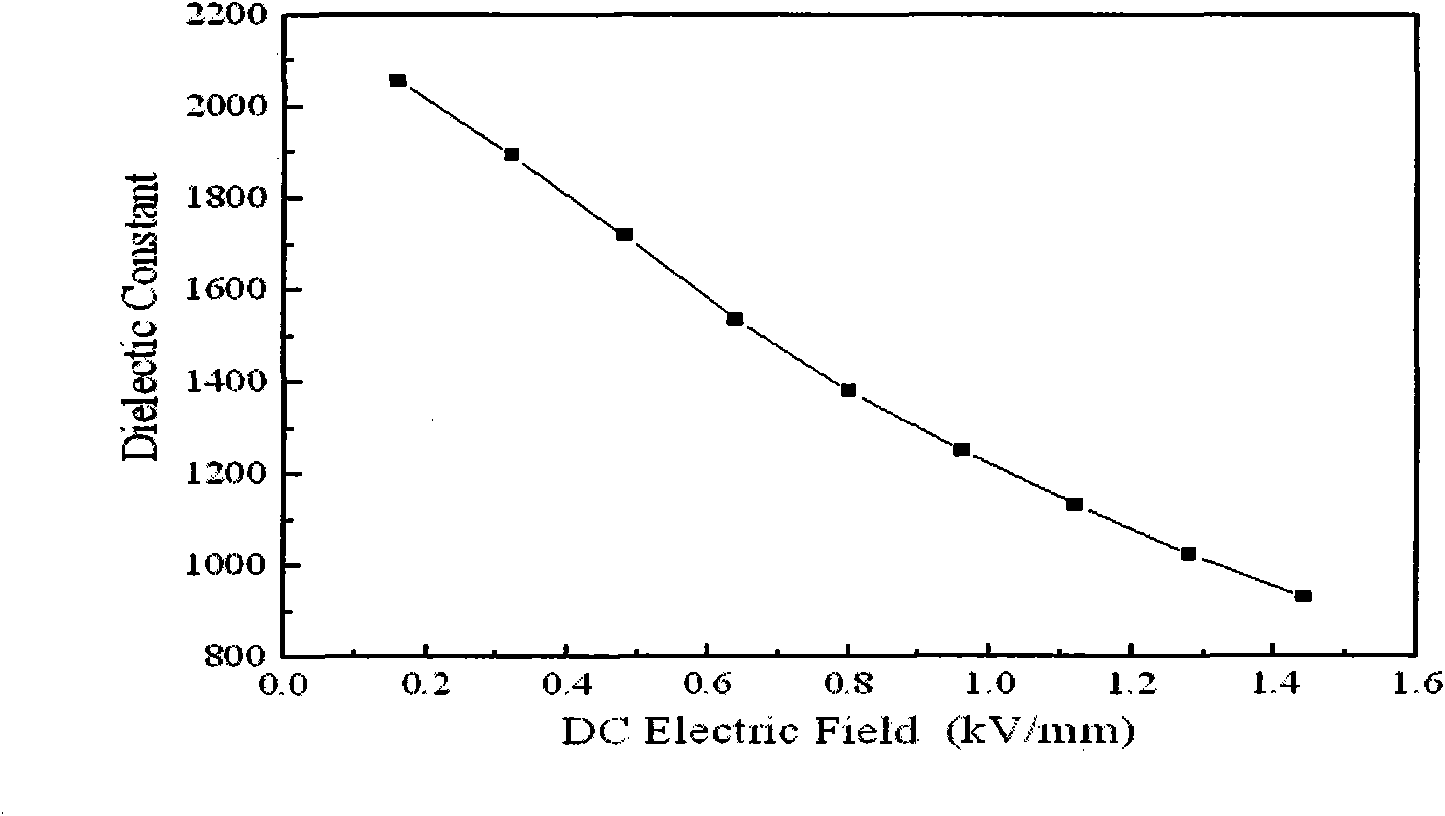

[0046] In this example, 90 g of ceramic materials with an adjustability of 42% were prepared.

[0047] In this embodiment, BaCO with a purity of 99.5%, 99.0% and 99.0% respectively 3 , SrCO 3 and TiO 2 Prepared Ba 0.6 Sr 0.4 TiO3 As the matrix material, ZnO and Al with a purity of 98.0%, 98.5% and 99.0% are added in combination 2 o 3 and MgO, whose composition is Ba 0.6 Sr 0.4 TiO 3 +xZnO+yAl 2 o 3 +10 wt% MgO, where x=1 wt%, y=25 wt%.

[0048] The concrete preparation steps of this embodiment are:

[0049] The first step, prepare Ba 0.6 Sr 0.4 TiO 3 Calcined powder; the BaCO 3 , SrCO 3 and TiO 2 Press Ba 0.6 Sr 0.4 TiO 3 Stoichiometric batching, adding 70ml of absolute ethanol medium to the batching, and ball milling for 20 hours to obtain a slurry; drying the slurry at 60°C for 10h to obtain a powder; pre-calcining the obtained powder at 1150°C for 3h to obtain Ba 0.6 Sr 0.4 TiO 3 Pre-fired powder;

[0050] The second step is to prepare the oxide comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com