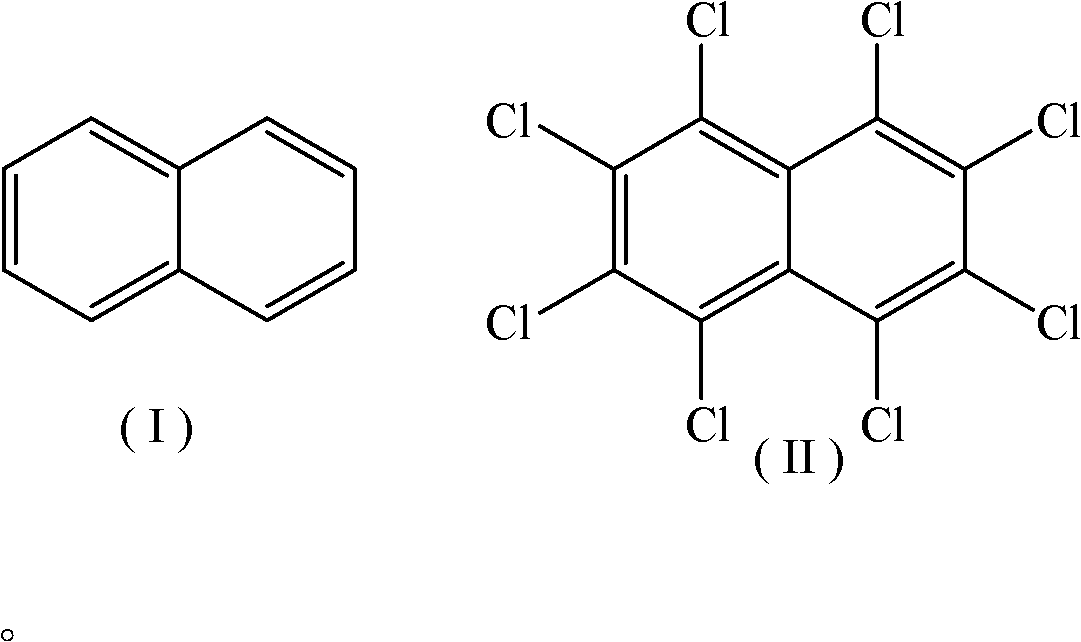

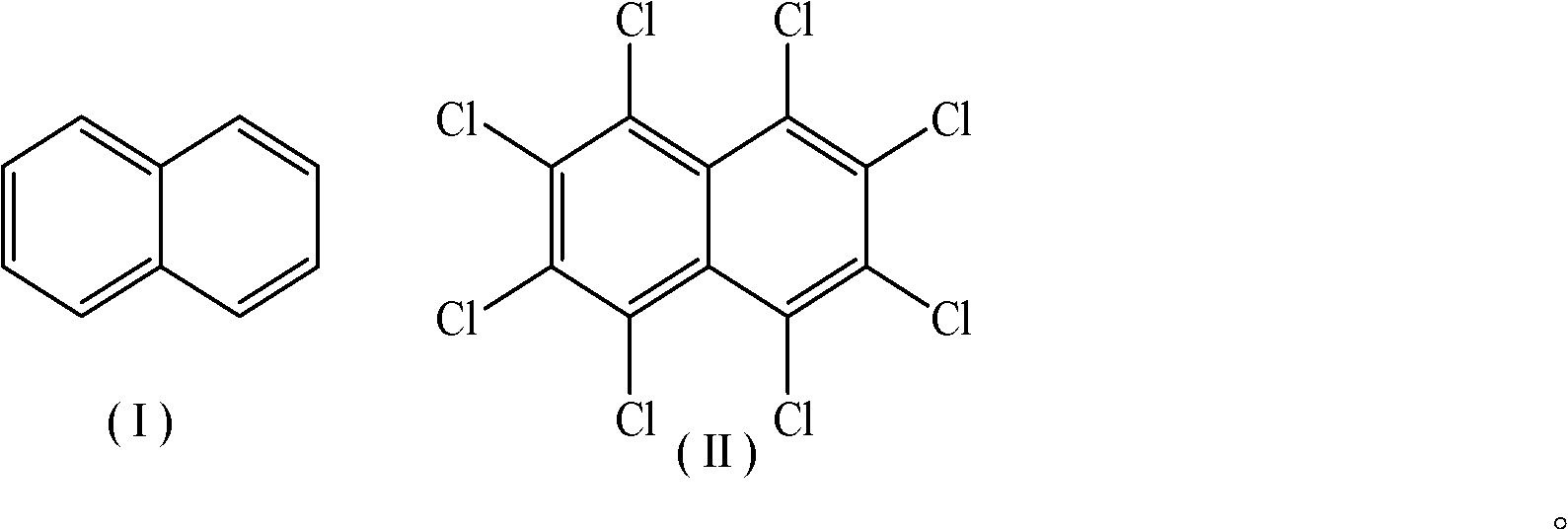

Method for preparing octachloronaphthalene

A technology of chloronaphthalene and chlorine gas is applied in the preparation of halogenated hydrocarbons, chemical instruments and methods, organic chemistry, etc., and achieves the effects of mild production conditions, high yield and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

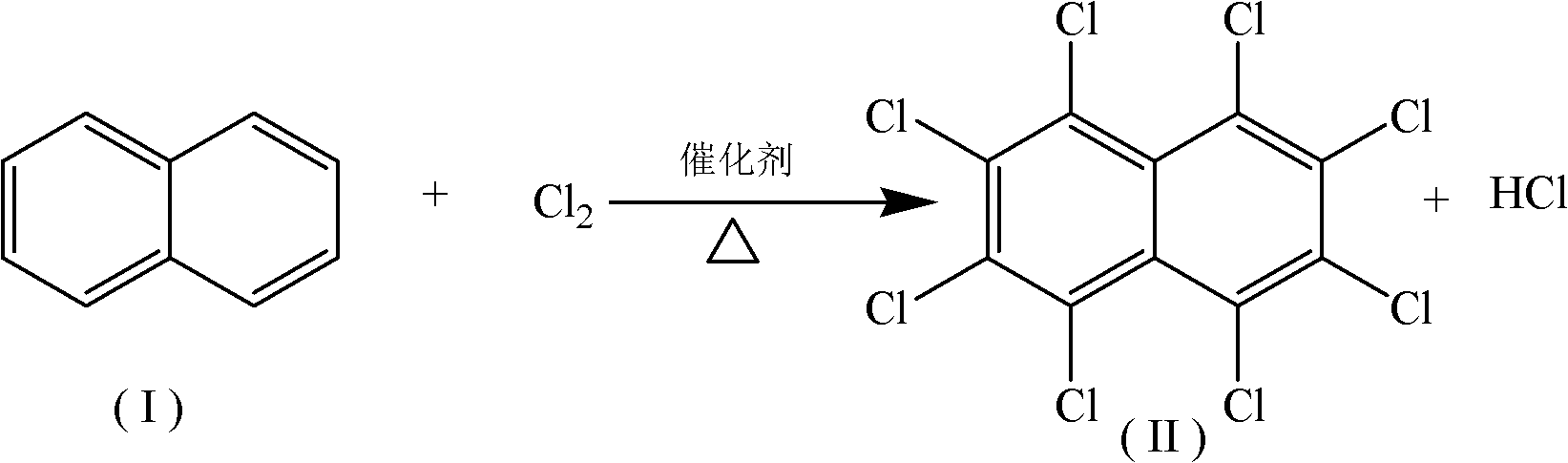

Method used

Image

Examples

example 1

[0023] Add 128 grams of naphthalene, 0.56 grams of iron powder, and 700 grams of carbon tetrachloride into a 1000ML three-necked flask, stir to dissolve all the solids, and slowly raise the temperature. When the temperature of the reaction solution reaches 60°C, start feeding chlorine gas and 570 grams of chlorine gas, the tail gas was absorbed with 1N sodium carbonate aqueous solution, after 24 hours of reaction, the temperature was lowered, and when the temperature dropped to room temperature, it was filtered and dried to obtain 345 grams of crude product, which was dissolved in 1000 grams of toluene, heated to 60 °C, and added 15 grams of activated carbon were incubated for 15 minutes, filtered, the solution was cooled to room temperature, and the product was precipitated, filtered, and dried to obtain 310 grams of product with a yield of 76.8%, mp 192-194 ° C (the thermometer was not corrected), and a purity of 97.7%. . (HPLC method, mobile phase is methanol, flow velocity...

example 2

[0025] Add 128 grams of naphthalene, 0.65 grams of zinc powder, and 700 grams of tetrachlorethylene into a 1000ML three-necked flask, stir to dissolve all the solids, and slowly raise the temperature. When the temperature of the reaction solution reaches 90°C, start to feed chlorine gas. 640 grams, the tail gas was absorbed with 1N potassium carbonate aqueous solution, and after reacting for 16 hours, the temperature was lowered. After the temperature dropped to room temperature, it was filtered and dried to obtain 305 grams of crude product, which was dissolved with 800 grams of ethanol. After being heated to 50°C, add 15 Gac gac, insulation 15 minutes, filter, solution is cooled to room temperature, separate out product, filter, dry, obtain 278 grams, yield is 68.8%, mp 194-196 ℃ (the thermometer is not corrected), purity 98.5%.

example 3

[0027] Add 128 grams of naphthalene, 0.65 grams of zinc powder, and 700 grams of tetrachloroethane into a 1000ML three-necked flask, stir to dissolve all the solids, and slowly raise the temperature. 710 grams of chlorine gas, the tail gas was absorbed with saturated ammonia solution, after reacting for 6 hours, the temperature was lowered, and when the temperature dropped to room temperature, it was filtered and dried to obtain 305 grams of crude product, dissolved in 800 grams of acetone, heated to 40 ° C, added 15 Gram gac, insulation 15 minutes, filter, solution is cooled to room temperature, separate out product, filter, dry, obtain 246 grams, yield is 60.9%, mp 193-195 ℃ (the thermometer is not corrected), purity 98.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com