Process for producing D(-)-tartaric acid by biotransformation

A biotransformation and tartaric acid technology, applied in the field of bioengineering, achieves the effects of good performance, reduced production costs, and reduced equipment volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

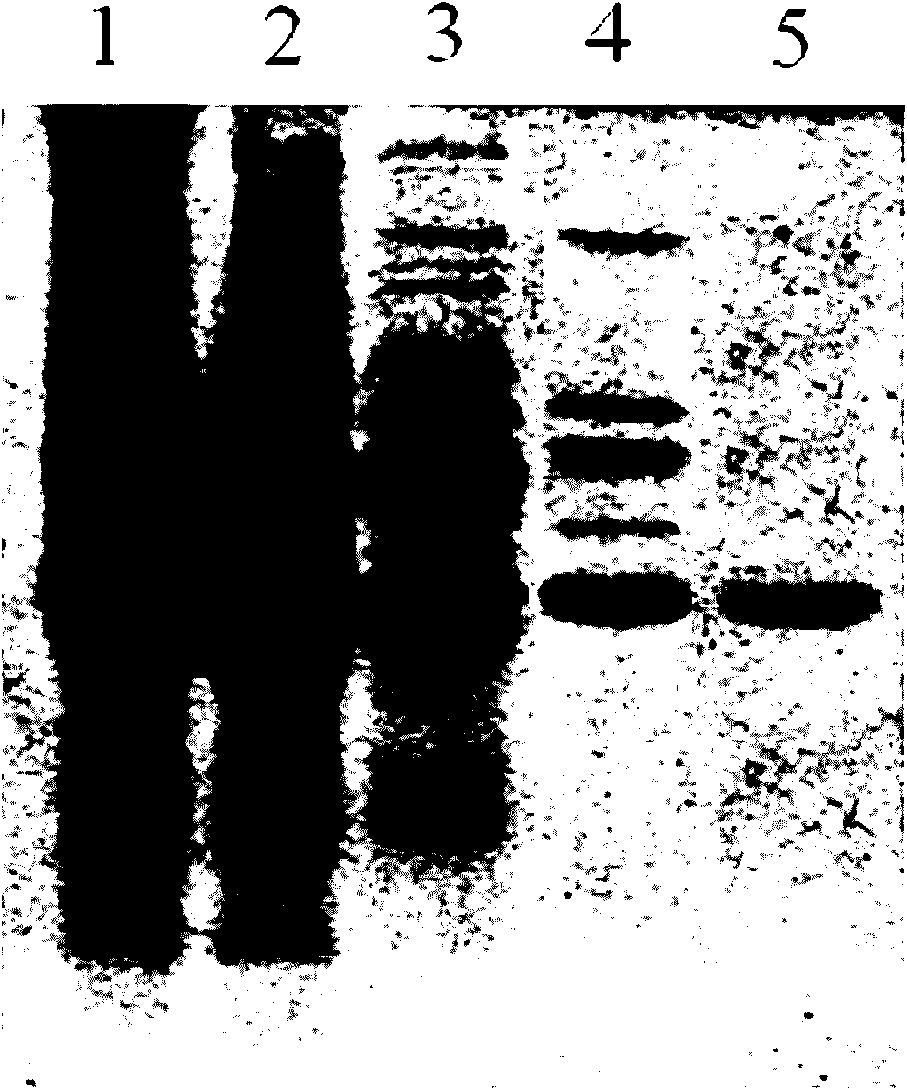

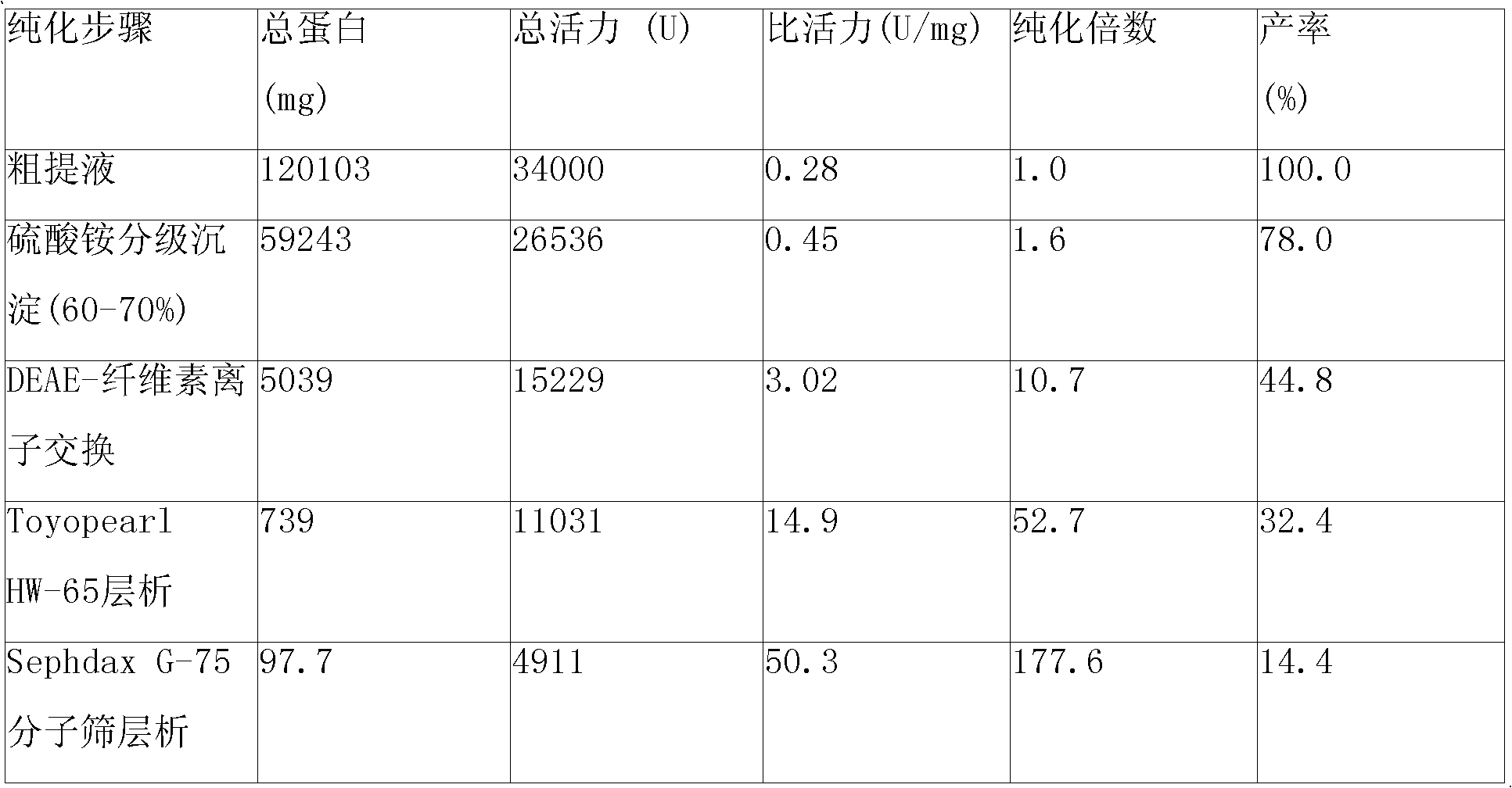

[0011] 1. Purification of cis-epoxysuccinate hydrolase

[0012] Use a strain (Bordetella sp.Strain 1-3) producing epoxysuccinate hydrolase, ferment in a 10-liter fermenter at 30°C for 30 hours, then centrifuge at 8000rpm for 20min to collect the bacteria, and use 50mmol / l pH 7.5 Cells were washed once with phosphate buffered saline. The formula of the fermentation broth is: yeast extract 7.8g / l, cis-epoxysuccinic acid 9.8g / l, KH 2 PO 4 1.12g / l, K 2 HPO 4 ·3H 2 O 3g / l, MgSO 4 ·7H 2 O 0.625g / l, trace element solution 12.5ml / l, pH 7.0. Afterwards, the obtained cells were suspended in 2 times the volume of 50 mmol / l pH 7.5 phosphate buffer, the cells were broken with a high-pressure homogenizer, and the cell wall fragments were removed by centrifugation at 8000 rpm for 20 min to obtain cis Crude extract of epoxysuccinate hydrolase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com