GaN-based LED epitaxial wafer and growing method thereof

An LED epitaxial wafer, GaN-based technology, applied in gaseous chemical plating, coating, electrical components, etc., can solve the problem that the antistatic ability of GaN-based LED chips is limited, and the dislocation of GaN-based epitaxial layers is not greatly reduced. Density and stress, etc., to achieve the effect of reducing dislocation density and improving working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

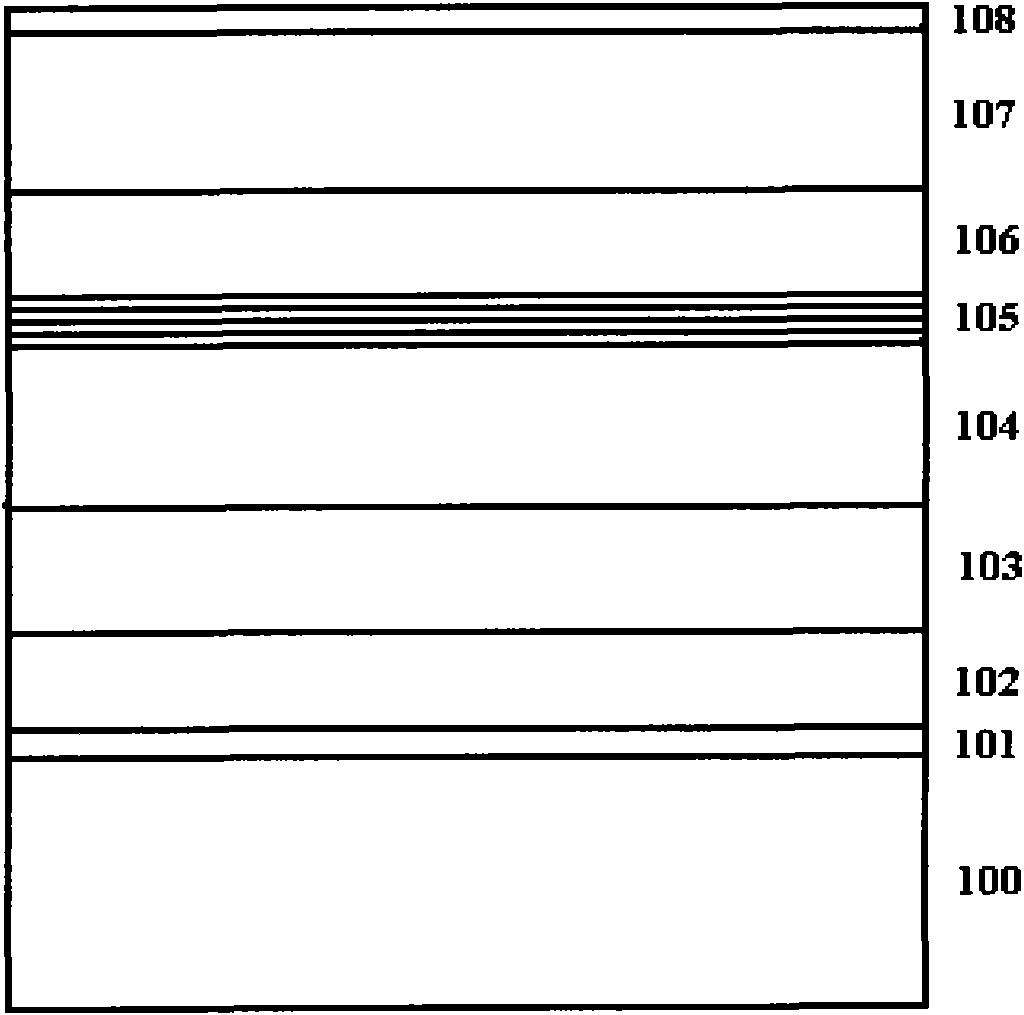

[0024] Embodiment 1 Using MOCVD to grow epitaxial wafers, grow sequentially from bottom to top:

[0025] 1. Put the sapphire substrate with (0001) crystal orientation into the reaction chamber, and then 2 The temperature in the environment is raised to 1050° C., stabilized for 10 minutes, and the substrate is purified at high temperature.

[0026] 2. Lower the temperature to 530° C. to grow a low-temperature GaN-based buffer layer with a thickness of 20 nm.

[0027] 3. Raise the temperature to 1100° C., keep the pressure at 500 Torr, and grow a first non-doped GaN layer with a thickness of 500 nm.

[0028]4. At 1100° C., a second non-doped GaN layer with a thickness of 1.5 μm is grown at a reduced pressure of 300 Torr.

[0029] 5. An n-type GaN layer with a thickness of 1.5 μm is grown at 1100° C.

[0030] 6. In N 2 The multi-quantum well layer is grown for 5 periods in the environment, the GaN barrier layer: the thickness is 20nm, the growth temperature is 850°C; the InGa...

Embodiment 2

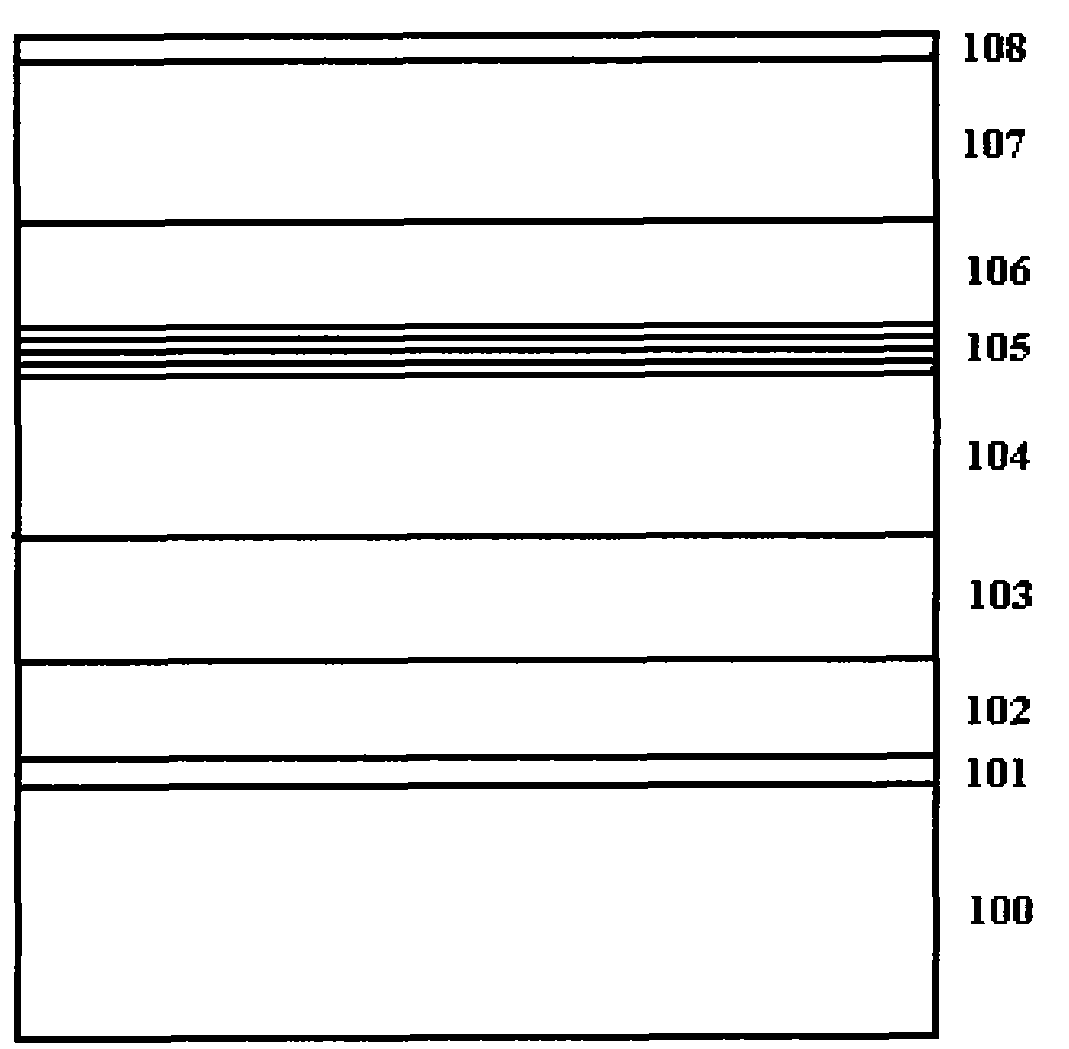

[0036] Embodiment 2 Using MOCVD to grow epitaxial wafers, grow sequentially from bottom to top:

[0037] 1. Put the sapphire substrate with (0001) crystal orientation into the reaction chamber, and then 2 The temperature in the environment is raised to 1250° C., stabilized for 5 minutes, and the substrate is purified at high temperature.

[0038] 2. Lower the temperature to 540° C. to grow a low-temperature GaN-based buffer layer with a thickness of 30 nm.

[0039] 3. Raise the temperature to 1200° C. and increase the pressure to 400 Torr to grow a first non-doped GaN layer with a thickness of 400 nm.

[0040] 4. At 1200° C., reduce the pressure to 200 Torr to grow a second non-doped GaN layer with a thickness of 1.6 μm.

[0041] 5. Grow n-type GaN with a thickness of 2 μm at 1200°C.

[0042] 6. In N 2 The multi-quantum well layer is grown for 15 cycles in the environment, the GaN barrier layer: the thickness is 13nm, the growth temperature is 950°C; the InGaN well layer: ...

Embodiment 3

[0049] Embodiment 3 Using MOCVD to grow epitaxial wafers, grow sequentially from bottom to top:

[0050] 1. Put the sapphire substrate with (0001) crystal orientation into the reaction chamber, and then 2 The temperature in the environment is raised to 1150° C., stabilized for 7 minutes, and the substrate is purified at high temperature.

[0051] 2. Lower the temperature to 550° C. to grow a low-temperature GaN-based buffer layer with a thickness of 25 nm.

[0052] 3. Raise the temperature to 1180° C. and increase the pressure to 300 Torr to grow a first non-doped GaN layer with a thickness of 50 nm.

[0053] 4. At 1180° C., reduce the pressure to 150 Torr to grow a second non-doped GaN layer with a thickness of 1.95 μm.

[0054] 5. A 3 μm thick n-type GaN layer was grown at 1180° C.

[0055] 6. In N 2 The multi-quantum well layer is grown for 10 periods in the environment, the GaN barrier layer: the thickness is 15nm, the growth temperature is 850°C; the InGaN well layer:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com