Bipolar plate frame and galvanic pile of flow battery

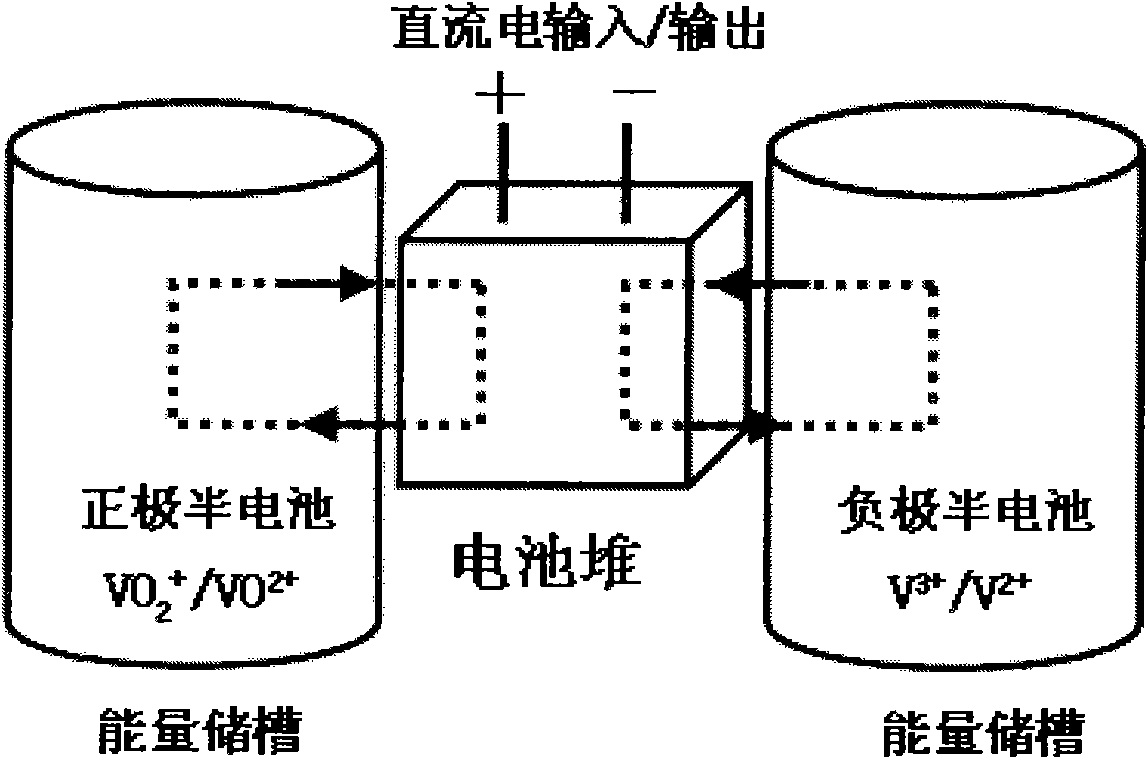

A liquid flow battery and bipolar plate technology, which is applied to battery electrodes, fuel cell parts, fuel cells, etc., can solve the problems of anolyte and catholyte leakage, self-discharge, etc., to reduce cost and improve work Efficiency, the effect of improving conversion and storage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

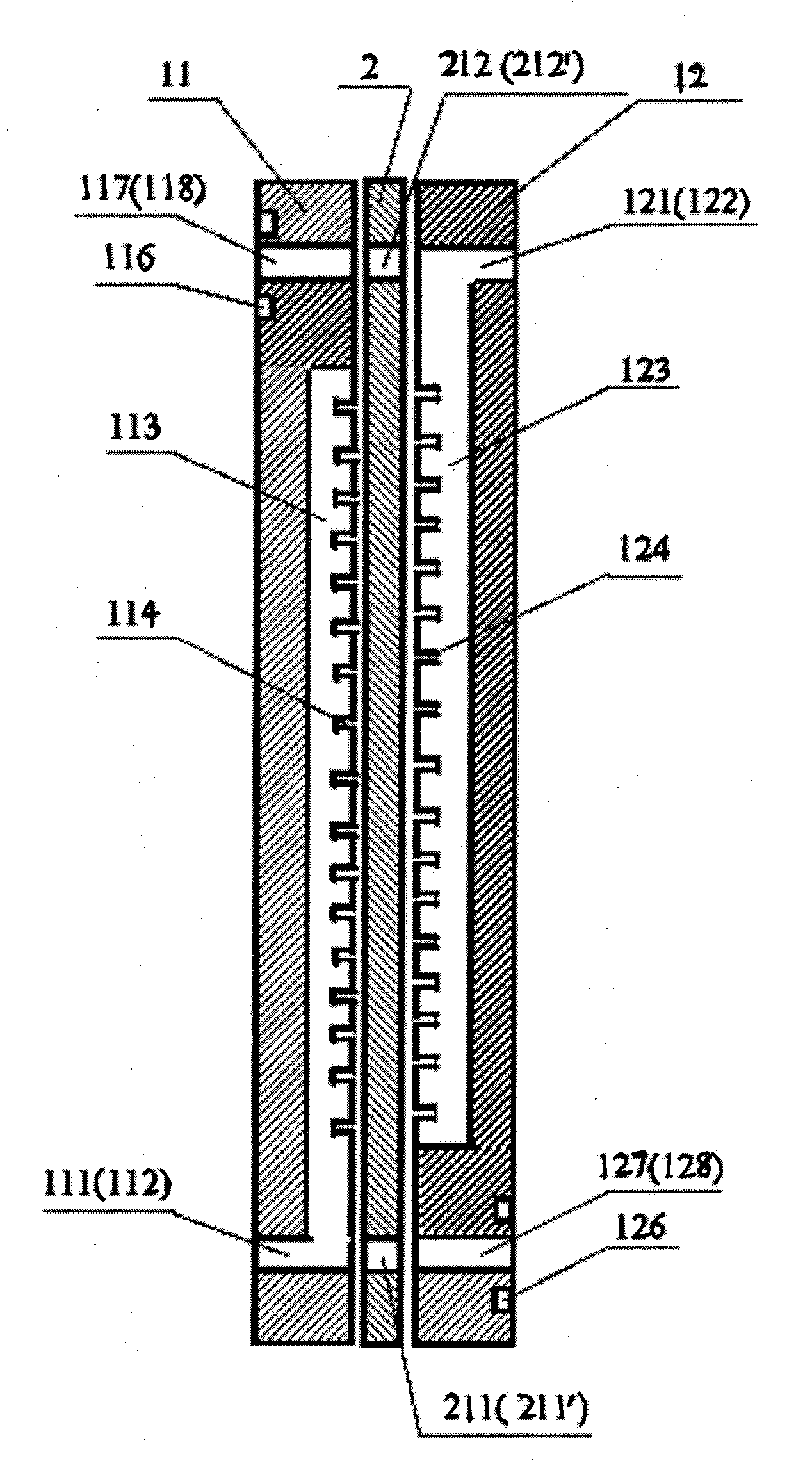

[0093] The structure of the bipolar plate frame and stack of the flow battery according to the present invention is further described as follows.

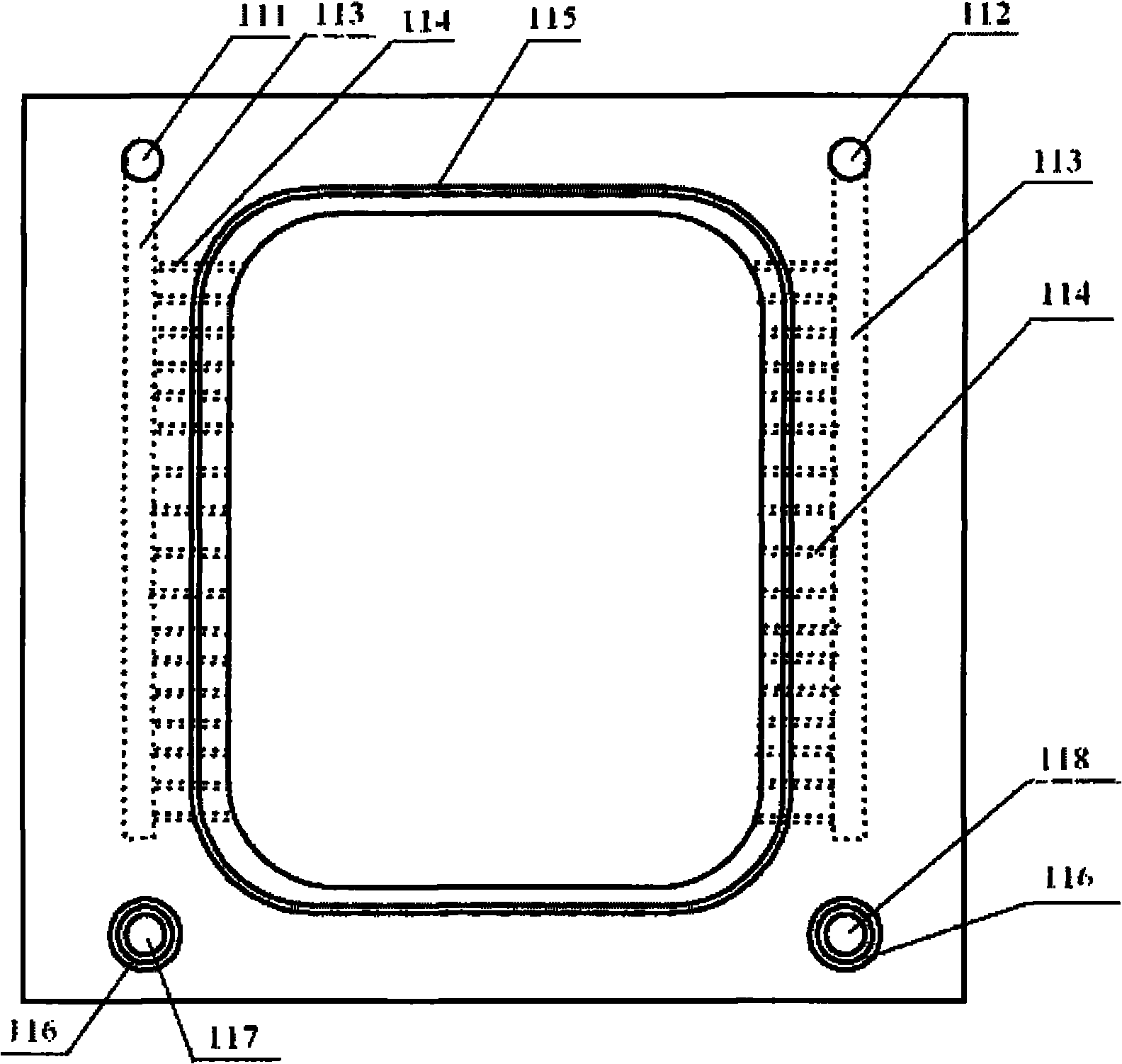

[0094] Upper electrode frame (11): The material is polyvinyl chloride, the length is 200 mm, the width is 200 mm, the thickness is 5 mm, the sealing groove is 3 mm wide, and the depth is 1.6 mm. The diameter of the first O-ring (115A) is 146 mm. Wire diameter 2.65 mm.

[0095] Bipolar plates (2): liquid-impermeable graphite, length 200 mm, width 200 mm, thickness 4 mm

[0096] The lower electrode frame (12): the material is polyvinyl chloride, the length is 200 mm, the width is 200 mm, the thickness is 5 mm, the sealing groove is 3 mm wide, and the depth is 1.6 mm. The diameter of the second O-ring (125A) is 132 mm. Wire diameter 2.65 mm.

[0097] The upper electrode frame, the lower electrode frame, and the liquid-impermeable graphite were bonded using polyvinyl chloride plastic adhesive. The bonded bipolar plate frame is used ...

Embodiment 2

[0103]The bipolar frame structure of the flow battery according to the present invention is further described as follows.

[0104] Upper electrode frame (11): material is polyvinylidene fluoride, length 850 mm, width 450 mm, thickness 4 mm, the first sealing groove (115) is 3 mm wide and 1.6 mm deep.

[0105] Bipolar plate (2): a bipolar plate made of conductive plastic, with a length of 850 mm, a width of 450 mm, a thickness of 2 mm, and a conductivity greater than 45 S / cm.

[0106] Lower electrode frame: the material is polyvinylidene fluoride, the length is 850 mm, the width is 450 mm, and the thickness is 4 mm. The second sealing groove (125) is 3 mm wide and 1.6 mm deep.

[0107] The upper electrode frame (11), the lower electrode frame (12) and the bipolar plate (2) made of conductive plastic are welded, and the integrated bipolar plate frame is used as a part.

[0108] O-ring C (7): use a neoprene O-ring with a wire diameter of 2.65 and a diameter of 18 mm for sealing....

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com