Preparation method of punicalagin molecular imprinted polymer microspheres

A technology of punicalagin and molecular imprinting, which is applied in the field of bioengineering, can solve problems such as the preparation method of punicalagin molecularly imprinted polymer microspheres that have not yet been discovered, and achieve the effects of low cost, simple preparation process and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

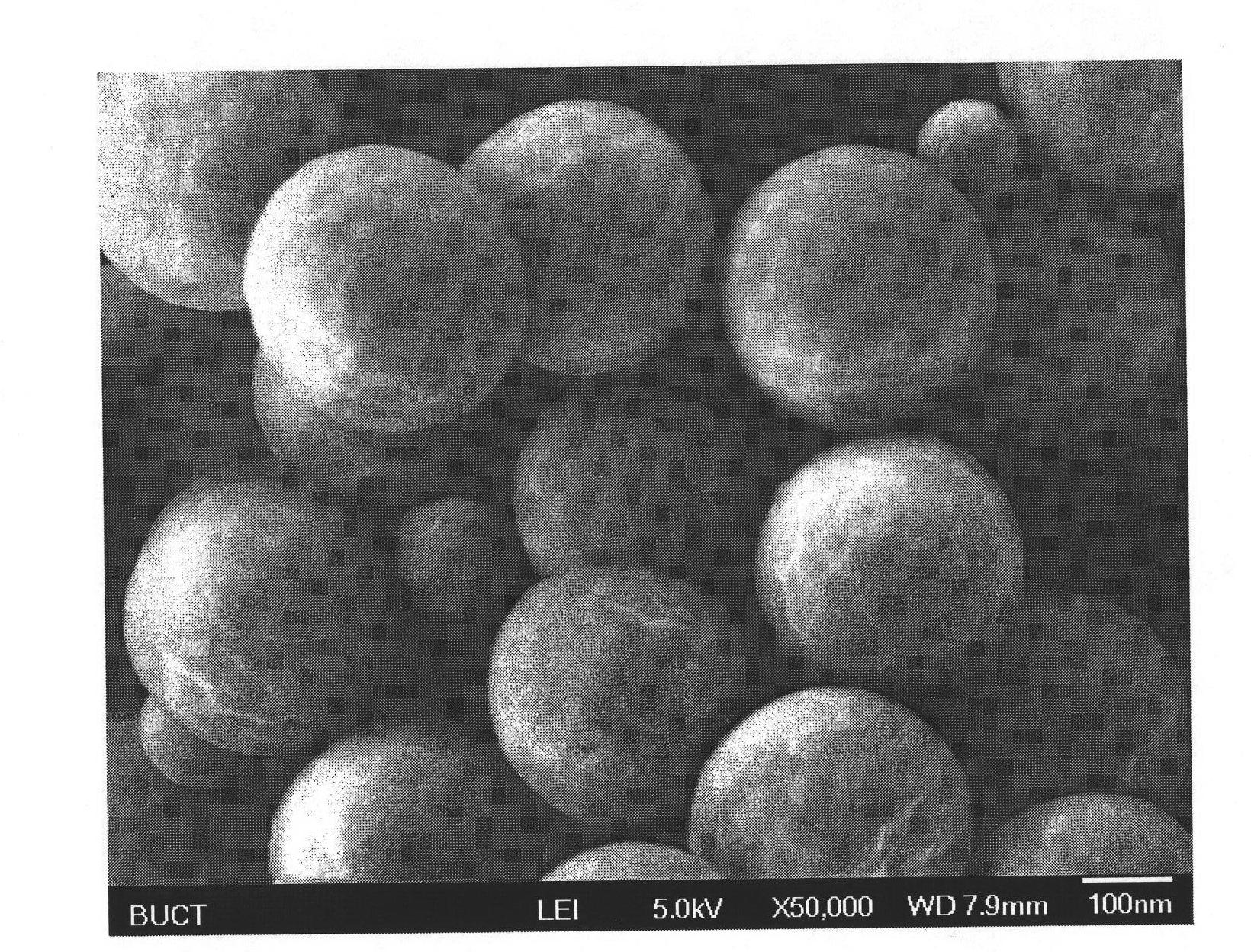

[0023] Weigh 0.1mmol of punicalagin template molecule, 1mmol of acrylamide, and 47.2ml of acetonitrile solution in a 100ml reaction flask, ultrasonically disperse at room temperature 25°C for 1h, then add 5mmolEDMA, initiator 0.0212g AIBN, ultrasonically disperse for 1h, and blow nitrogen Deoxygenate for 20 minutes, seal, and stir at 400 rpm for 24 hours at 60°C.

[0024] The resulting mixture was centrifuged at 4000 rpm for 20 min, and the supernatant was filtered off to obtain a polymer, which was dried at 50° C. for 24 h.

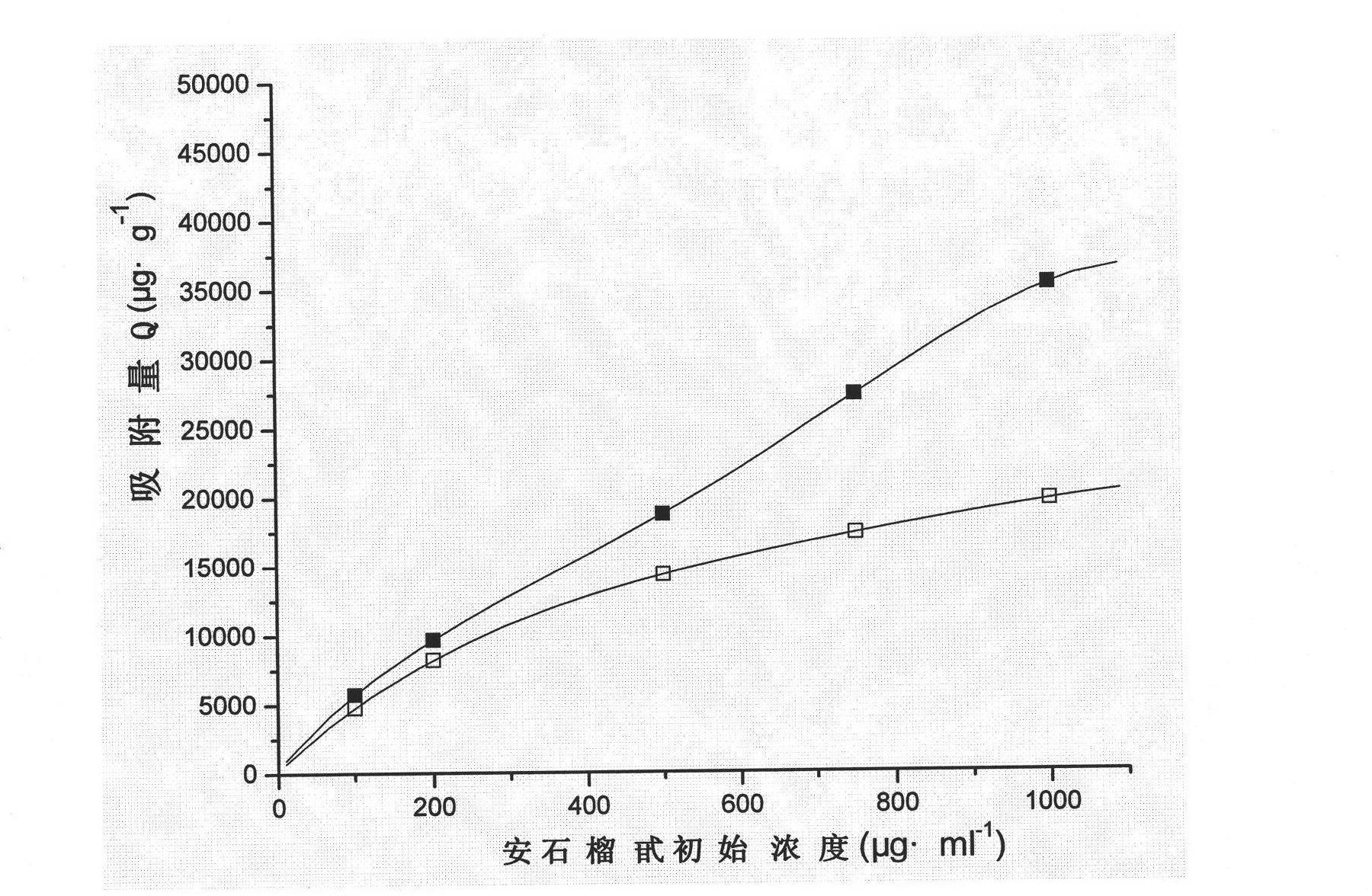

[0025] The polymer was subjected to Soxhlet extraction with methanol:acetic acid (80:20, V / V) for 48 hours to remove template molecules, and was detected with a UV-Vis spectrophotometer until no template molecules were detected. The polymer obtained after the extraction was dried at 50° C. for 24 hours to finally obtain the molecularly imprinted polymer of punicalagin. The effect of its invention is as figure 1 shown.

[0026] Prepare a blank polymer ...

Embodiment 2

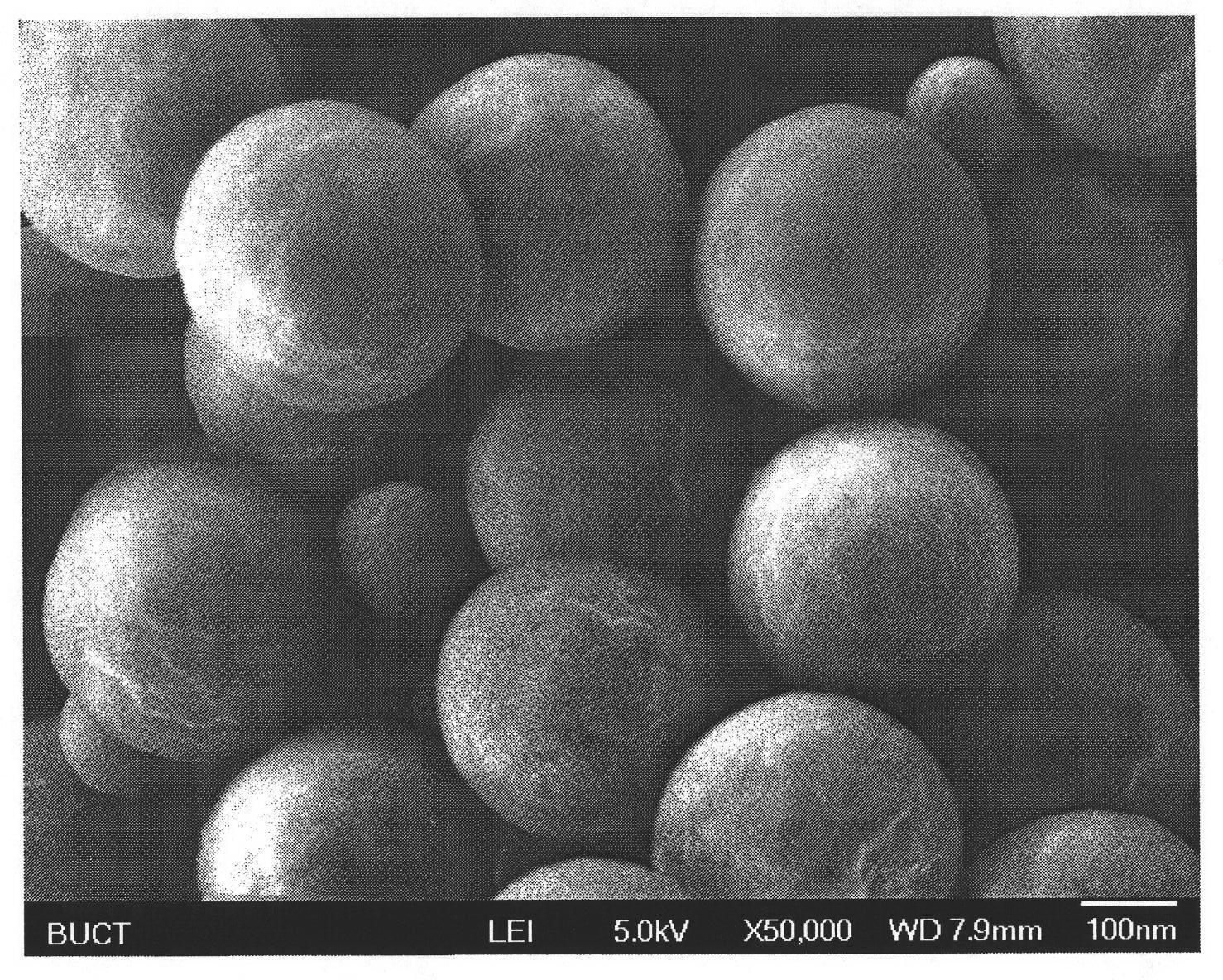

[0031] Weigh 0.1 mmol of punicalagin template molecule, 0.5 mmol of acrylamide, and 23.6 ml of acetonitrile solution in a 100 ml reaction flask for ultrasonic dispersion at room temperature 25°C for 1 hour, then add 5 mmol of EDMA, 0.0212 g of AIBN as an initiator, ultrasonic dispersion for 1 hour, and nitrogen gas Deoxygenate for 20 minutes, seal, and stir at 400 rpm for 24 hours at 60°C.

[0032] The resulting mixture was centrifuged at 4000 rpm for 20 min, and the supernatant was filtered off to obtain a polymer, which was dried at 50° C. for 24 h.

[0033] The polymer was subjected to Soxhlet extraction with methanol:acetic acid (80:20, V / V) for 48 hours to remove template molecules, and was detected with a UV-Vis spectrophotometer until no template molecules were detected. The polymer obtained after the extraction was dried at 50° C. for 24 hours to finally obtain the molecularly imprinted polymer of punicalagin. Its invention effect is basically equal to as figure 1 sh...

Embodiment 3

[0039] Weigh 0.05mmol of punicalagin template molecule, 1mmol of acrylamide, and 47.2ml of acetonitrile solution in a 100ml reaction flask, ultrasonically disperse at room temperature 25°C for 1h, then add 5mmol of EDMA, 0.0212g of AIBN as an initiator, ultrasonically disperse for 1h, and blow in nitrogen Deoxygenate for 20 minutes, seal, and stir at 400 rpm for 24 hours at 60°C.

[0040] The resulting mixture was centrifuged at 4000 rpm for 20 min, and the supernatant was filtered off to obtain a polymer, which was dried at 50° C. for 24 h.

[0041] The polymer was subjected to Soxhlet extraction with methanol:acetic acid (80:20, V / V) for 48 hours to remove template molecules, and was detected with a UV-Vis spectrophotometer until no template molecules were detected. The polymer obtained after the extraction was dried at 50° C. for 24 hours to finally obtain the molecularly imprinted polymer of punicalagin. The effect of its invention is basically equivalent to figure 1 sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com