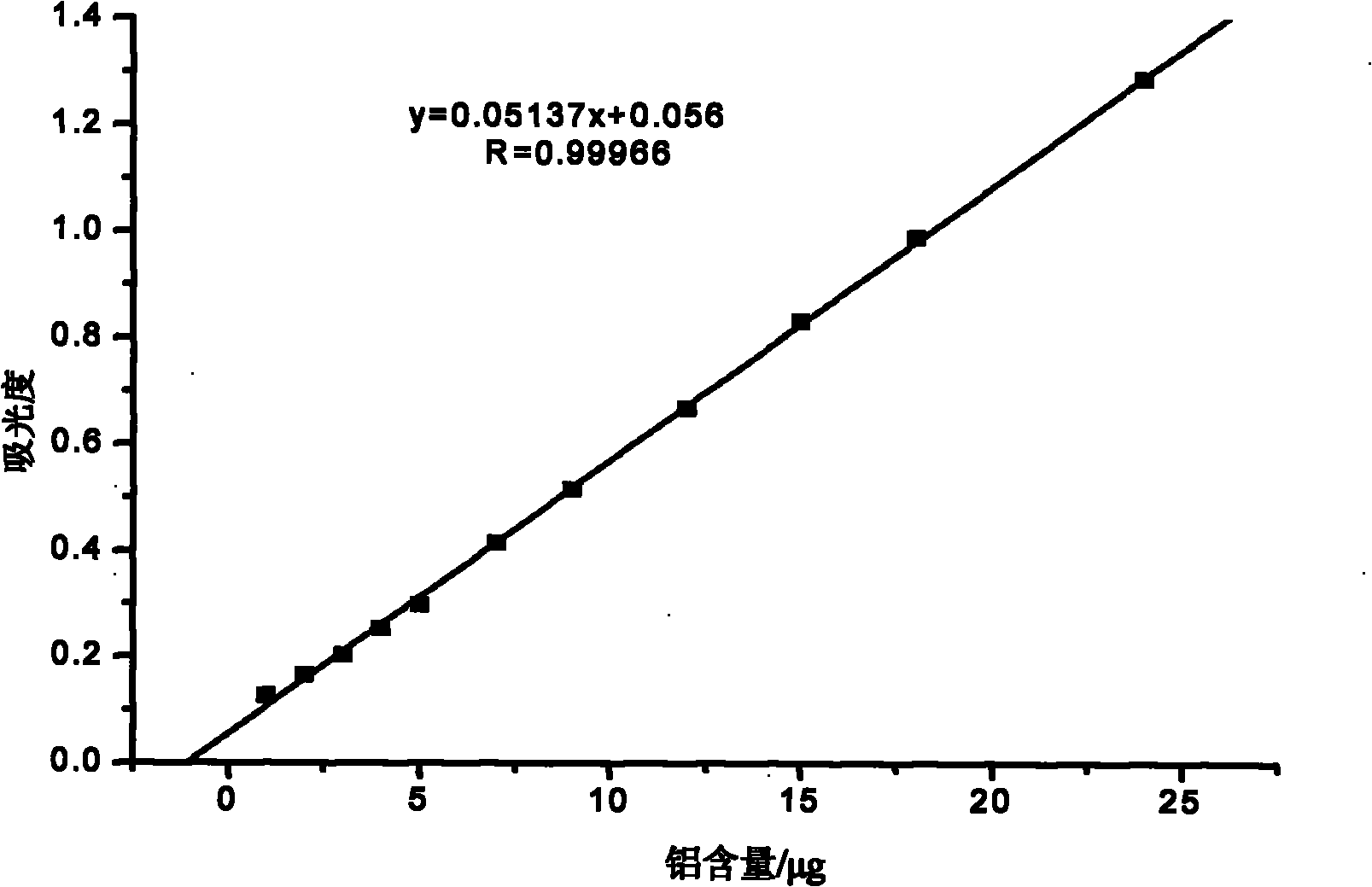

Method for detecting activity of metakaolin by using spectrophotometer

A spectrophotometer, metakaolin technology, applied in the measurement of color/spectral properties, etc., can solve the problems of inconvenient detection, inconspicuous color change, and difficulty in judging the titration end point, achieving less sample volume, fast analysis speed, and low equipment cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

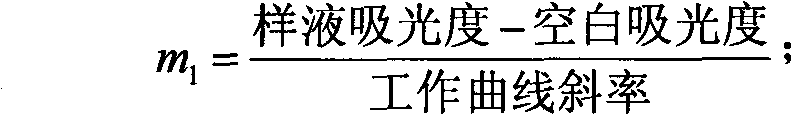

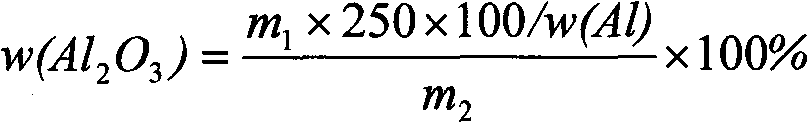

Method used

Image

Examples

Embodiment 1

[0042] 1) Zhangzhou iron dyed kaolin is used as raw material. where Al 2 o 3 The content is 38.24%, Fe 2 o 3 The content is 0.94%. The main mineral composition is kaolinite and a small amount of quartz, and the mineral structure is flake and a large number of tubes.

[0043] 2) Calcining Zhangzhou iron-dyed kaolin in a high-temperature energy-saving electric furnace. Kaolin is finely ground and passed through a 100-mesh sieve. The heating rate was 7.5°C / min, the calcination temperatures were 500°C, 600°C, 700°C, 800°C, 900°C, 1000°C, and the calcination time was 2h. After the calcination, the kaolin was cooled to room temperature with the furnace, and the metakaolin sample was taken out.

[0044] 3) Weigh about 1g of metakaolin sample and pour it into a 250mL three-necked flask. Then pour 20mL of 15% hydrochloric acid, heat to 80°C in a constant temperature water bath, and stir for 2h. The liquid-solid mixture in the three-necked flask was cooled, filtered and washed....

Embodiment 2

[0050] Raw material and analysis test process are with embodiment 1. Kaolin is passed through a 100-mesh sieve. When calcining kaolin, the heating rate is 7.5°C / min, the calcining temperature is 700°C, and the calcining time is 2h, 4h, 6h, 8h, and 10h respectively. The measured activated alumina contents are respectively: 17.84%, 18.72%, 19.02%, 19.56%, 19.86%. The compressive strengths of the prepared geopolymeric cementitious materials are 55.26MPa, 57.59MPa, 58.02MPa, 58.96MPa, 59.46MPa respectively. It has a good correspondence with the determined active alumina content.

Embodiment 3

[0052] Raw material and analysis test process are with embodiment 1. Kaolin is passed through a 100-mesh sieve. When calcining kaolin, the heating rates were 2.5°C / min, 5°C / min, 7.5°C / min, and 10°C / min. The calcination temperature is 700° C., and the calcination time is 2 hours respectively. The measured activated alumina contents are respectively: 16.32%, 17.13%, 17.84%, and 18.26%. The compressive strengths of the prepared geopolymeric cementitious materials are 54.78MPa, 54.92MPa, 55.26MPa and 55.56MPa respectively. It has a good correspondence with the determined active alumina content.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com