Ketoconazole foaming agent and preparation method thereof

A technology for foaming agent and ketoconazole medicine, applied in the field of pharmacy, can solve the problems of hidden dangers in daily use, difficult to control, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

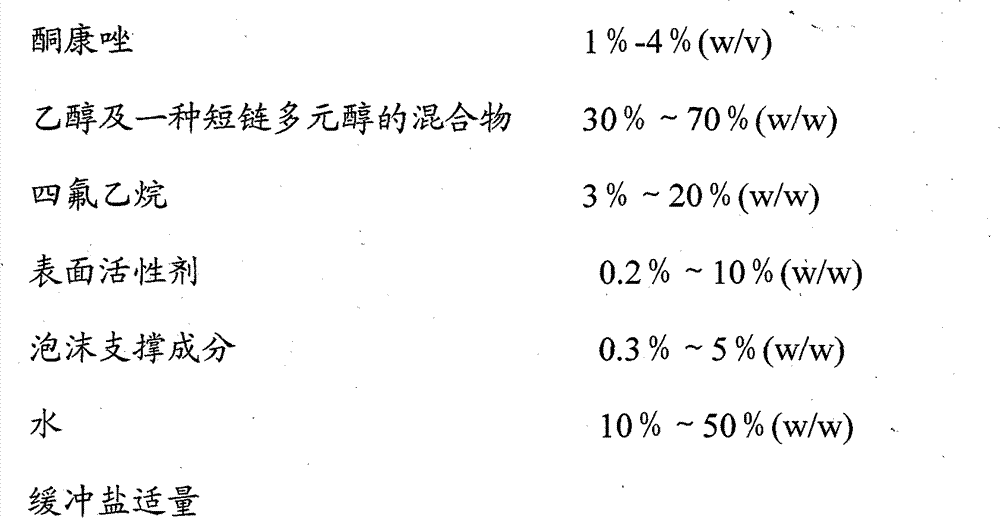

Method used

Image

Examples

Embodiment 1

[0029] Weigh and mix the absolute ethanol and propylene glycol as the solvent and keep the temperature at 50-60°C for use.

[0030] Add stearyl alcohol and stir at 60°C to complete the dissolution. Keep the temperature at 50-60°C for use.

[0031] Weigh the ketoconazole and add it to the above solvent to make the dissolution complete and make the alcohol phase.

[0032] Weigh Tween 60 and citrate buffer solution into the prescribed amount of water to make the dissolution completely, and make the water phase.

[0033] Keep the temperature at 50-60°C, and slowly add the water phase to the alcohol phase.

[0034] Keep the temperature at 50°C, stir for 30 minutes, stop heating, and continue stirring to about 40°C. Filling, sealing, capping.

[0035] Fill with propellant.

[0036] Citrate buffer preparation method: take 10% potassium citrate solution, use 10% citric acid solution, adjust the pH value to 7.0.

Embodiment 2

[0039] Weigh and mix the absolute ethanol and propylene glycol as the solvent and keep the temperature at 40°C for use.

[0040] Add stearyl alcohol, stir at 60°C to make the dissolution complete, keep the temperature at 40°C, and set aside.

[0041] Weigh the ketoconazole and add it to the above solvent to make the dissolution complete and make the alcohol phase.

[0042] Weigh Tween 60 and citrate buffer solution into the prescribed amount of water to make the dissolution complete and prepare the water phase.

[0043] Keep the temperature at 40°C and slowly add the water phase to the alcohol phase.

[0044] Keep the temperature at 40°C and stir for 1 hour.

[0045] Filling, sealing, capping.

[0046] Fill with propellant.

[0047] Citrate buffer preparation method: the same as in Example 1.

[0048] The state of the sample prepared by the method in Example 2 is not significantly different from that of the sample prepared in Example 1.

Embodiment 3

[0051] Weigh and mix the absolute ethanol and propylene glycol as the solvent and keep the temperature at 40°C for use.

[0052] Add stearyl alcohol, stir at 60°C to make the dissolution complete, keep the temperature at 40°C, and set aside.

[0053] Weigh the ketoconazole and add it to the above solvent to make the dissolution complete and make the alcohol phase.

[0054] Weigh Tween 60 and citrate buffer solution into the prescribed amount of water to make the dissolution complete and prepare the water phase.

[0055] Keep the temperature at 40°C and slowly add the water phase to the alcohol phase.

[0056] Keep the temperature at 40°C and stir for 1 hour.

[0057] Filling, sealing, capping.

[0058] Fill with propellant.

[0059] Citrate buffer preparation method: the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com