Cross-linked polymer gel and preparation method thereof

A technology of cross-linked polymer and colloid, applied in the field of ground room-temperature cross-linked polymer jelly and its preparation, can solve the problem that the temperature resistance of surfactants is not ideal, it is difficult to increase the speed and reduce filtration, Liquid filtration is not easy to control and other problems, to achieve the effect of improving acid pressure and economic benefits, good temperature stability and shear resistance, and good temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

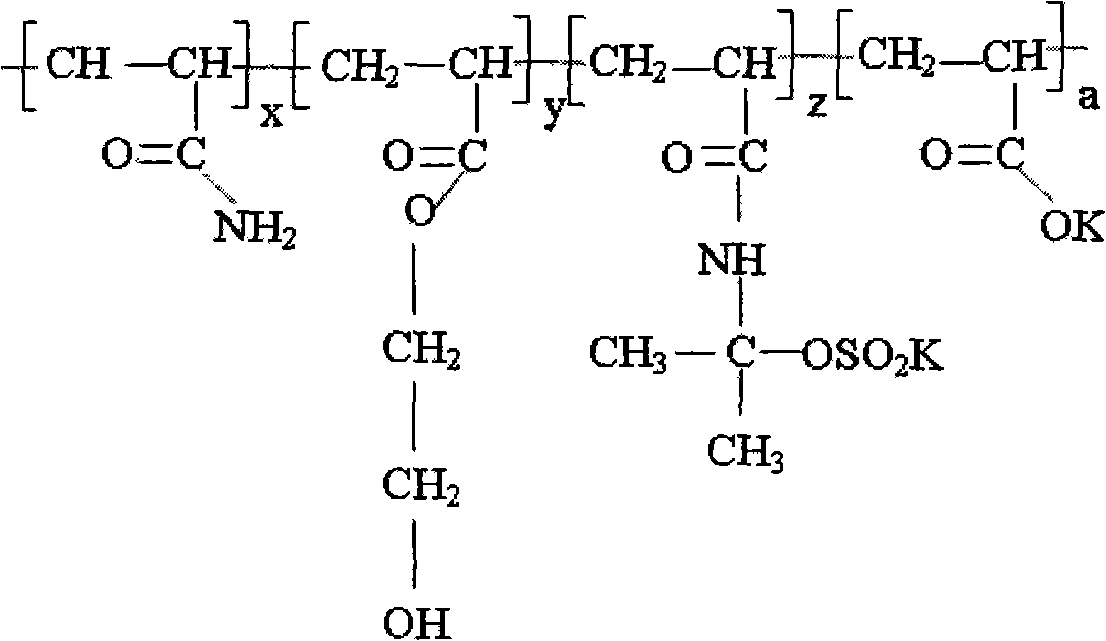

[0047] A cross-linked polymer jelly body, the system is composed of a cross-linked polymer and a cross-linking agent;

[0048] The steps of the preparation method of described cross-linked polymer jelly body are:

[0049] I. Synthesis of cross-linked polymers:

[0050] A. the synthesis of acrylate-2-hydroxyethyl ester: add acrylic acid, catalyzer, polymerization inhibitor in reactor, the pressure of reactor is raised to 0.4MPa, slowly feed oxyethane in this reactor; The temperature in the reactor is controlled at 60°C to 80°C, and the contents in the reactor are stirred and reacted for 8 to 12 hours; then the reactor is cooled to normal temperature, and the product in the reactor is subjected to vacuum distillation , at a pressure of 1.6Kpa, the fraction with a boiling point between 90 and 92°C was collected to obtain a colorless transparent liquid, which was the target product;

[0051] The weight ratio of described acrylic acid and ethylene oxide is 1.46-1.80: 1.0-1.25;

...

Embodiment 2

[0085] This embodiment is a preferred scheme based on embodiment 1, and the quality of raw materials used, the type and source of the instrument used are the same as in embodiment 1;

[0086] The steps of the preparation method of the cross-linked polymer jelly body refer to Example 1, the difference is:

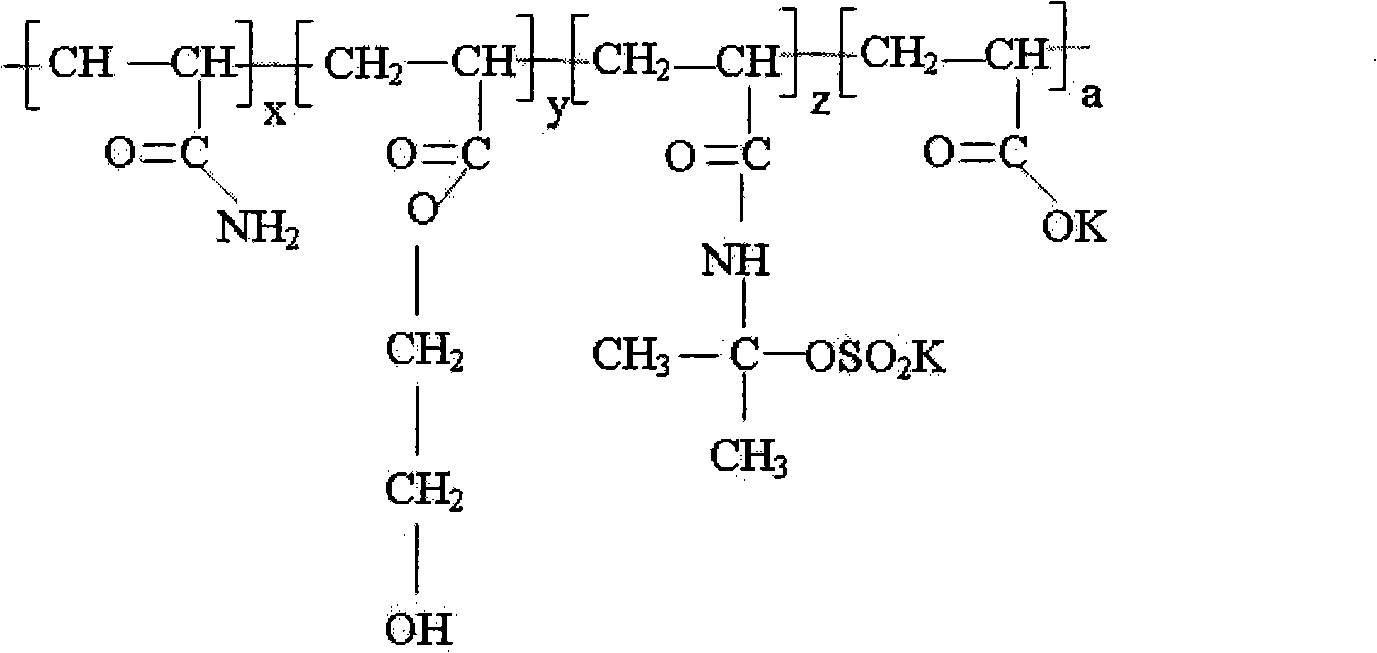

[0087] I. Synthesis of cross-linked polymers:

[0088] In step A:

[0089] The weight ratio of described acrylic acid and oxirane is 1.46: 1.0;

[0090] The catalyst is an iron catalyst catalyst, and its weight accounts for 1% of the weight of acrylic acid;

[0091] Described polymerization inhibitor is p-hydroxyanisole, and weight accounts for 400ppm of the total weight of described acrylic acid, described catalyst, described polymerization inhibitor;

[0092] In step B:

[0093] The weight ratio of the 2-acrylamido 2-methylpropanesulfonic acid (AMPS), acrylic acid (AA), and deionized water is 18:1:55;

[0094] Described carbonate is the one in potassium carbonate, pot...

Embodiment 3

[0115] This embodiment is a preferred scheme based on embodiment 1, and the quality of raw materials used, the type and source of the instrument used are the same as in embodiment 1;

[0116] The steps of the preparation method of the cross-linked polymer jelly body refer to Example 1, the difference is:

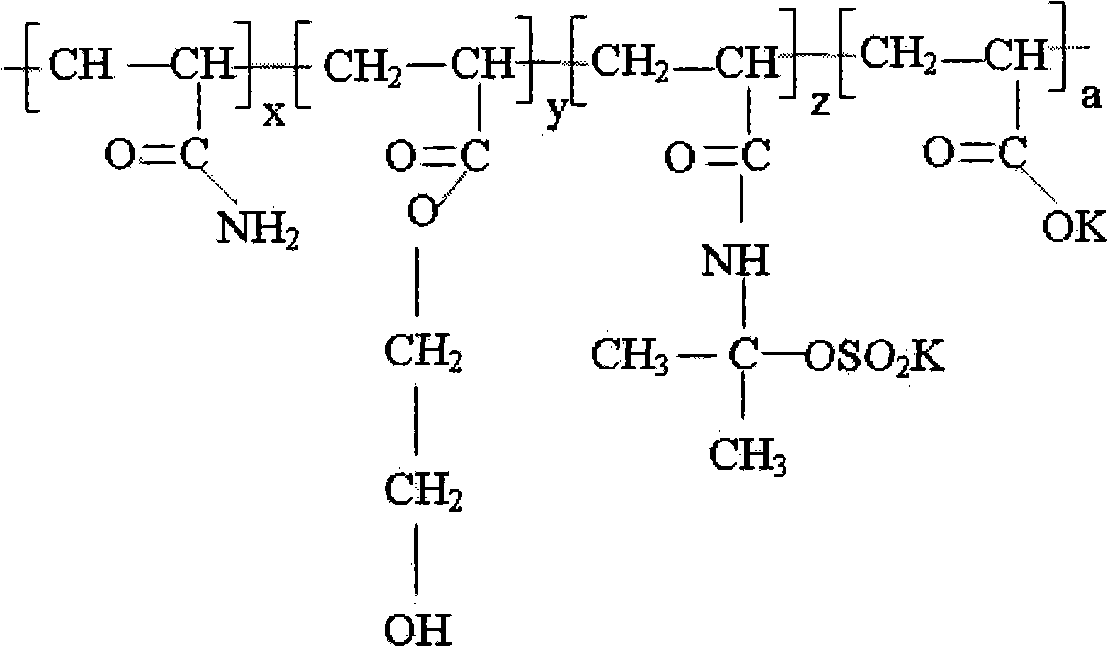

[0117] I. Synthesis of cross-linked polymers:

[0118] In step A:

[0119] The weight ratio of described acrylic acid and oxirane is 1.80: 1.25;

[0120] The catalyst is an iron catalyst catalyst, and its weight accounts for 3% of the weight of acrylic acid;

[0121] Described polymerization inhibitor is p-hydroxyanisole, and weight accounts for 1000ppm of the total weight of described acrylic acid, described catalyst, described polymerization inhibitor;

[0122] In step B:

[0123] The weight ratio of the 2-acrylamido 2-methylpropanesulfonic acid (AMPS), acrylic acid (AA), and deionized water is 25:1.5:40;

[0124] Described carbonate is a kind of in sodium carbonate, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com